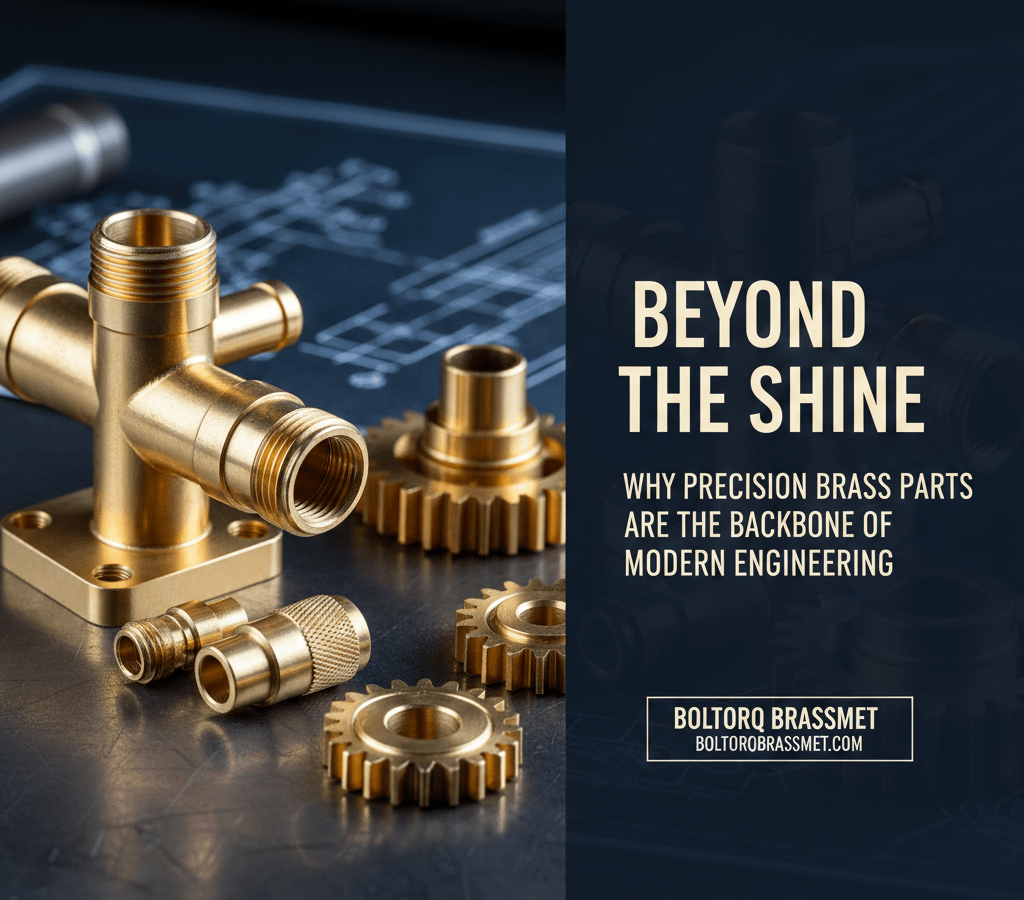

Why Precision Brass Parts are the Backbone of Modern Engineering

In the world of industrial manufacturing, the “best” material isn’t always the strongest or the cheapest—it’s the one that performs most reliably under pressure. If you are an engineer, a procurement head, or a product designer, you know that a single faulty fitting can halt an entire production line.

That is why brass parts remain the gold standard. While stainless steel has its place, the unique synergy of copper and zinc in brass creates a material that doesn’t just “work”—it excels in environments where precision is non-negotiable.

The Engineer’s Choice: Why Brass Wins the Specs Race

When we talk about high-performance components, we aren’t just looking at a piece of metal; we are looking at machinability, conductivity, and durability. Here is why seasoned professionals choose brass over alternatives:

- Zero-Fail Machinability: High-grade brass (like C360) is known as “free-cutting” for a reason. It allows for incredibly tight tolerances—often down to +-0.001″—without the tool wear or material warping common with stainless steel.

- Thermal & Electrical Superiority: With electrical conductivity up to 15 times higher than stainless steel, brass is the essential choice for connectors, terminals, and switchgear.

- Natural Corrosion Resistance: Unlike ferrous metals, brass does not rust. Its inherent resistance to moisture and salt makes it the primary choice for marine hardware and underground plumbing systems.

- The “Sealing” Factor: Brass is slightly softer than steel, which is actually a strategic advantage. It allows threaded brass parts to create a tighter, leak-proof seal in hydraulic and gas applications without the risk of galling.

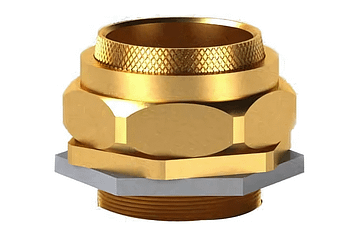

Read Also: Why Brass Cable Glands are the Gold Standard for Industrial Wiring Safety

Versatility Across Critical Industries

The true value of a brass component lies in its ability to adapt. At Boltorq Brassmet, we see these parts driving innovation across four key sectors:

1. Electrical & Electronics

From miniature pins in consumer electronics to heavy-duty neutral links in power distribution, brass ensures low resistance and high reliability. It’s the silent partner in every circuit that stays cool under load.

2. Automotive & Aerospace

Modern vehicles require sensors and fuel system components that can withstand constant vibration and temperature shifts. Brass inserts and forged parts provide the structural integrity needed for safety-critical systems.

3. Plumbing & HVAC

Because it resists mineral buildup and handles high-pressure water delivery without degrading, brass is the only logical choice for valves, manifolds, and fittings that are meant to last decades, not years.

4. Marine Engineering

Naval-grade brass is specifically alloyed to withstand the harshest saltwater environments, preventing the “dezincification” that causes lesser metals to crumble.

Quality is Not an Accident

As a professional in this space, you know that “cheap” brass is often the most expensive mistake you can make. Subpar alloys lead to brittle parts and inconsistent dimensions.

High-value manufacturing requires spectroscopy analysis to verify alloy composition and CNC precision to ensure every part in a 10,000-unit run is identical to the first. When you source brass products, you aren’t just buying metal; you are buying the assurance that your assembly will perform exactly as designed.

Secure Your Supply Chain with Precision

Whether you are designing a new medical instrument or upgrading an industrial HVAC system, the components you choose define your brand’s reputation for quality. Don’t settle for “good enough” when you can have precision-engineered reliability.

Explore our full range of high-performance brass components and custom-machined solutions:

0 Comments