Why Brass Cable Glands are the Gold Standard for Industrial Wiring Safety

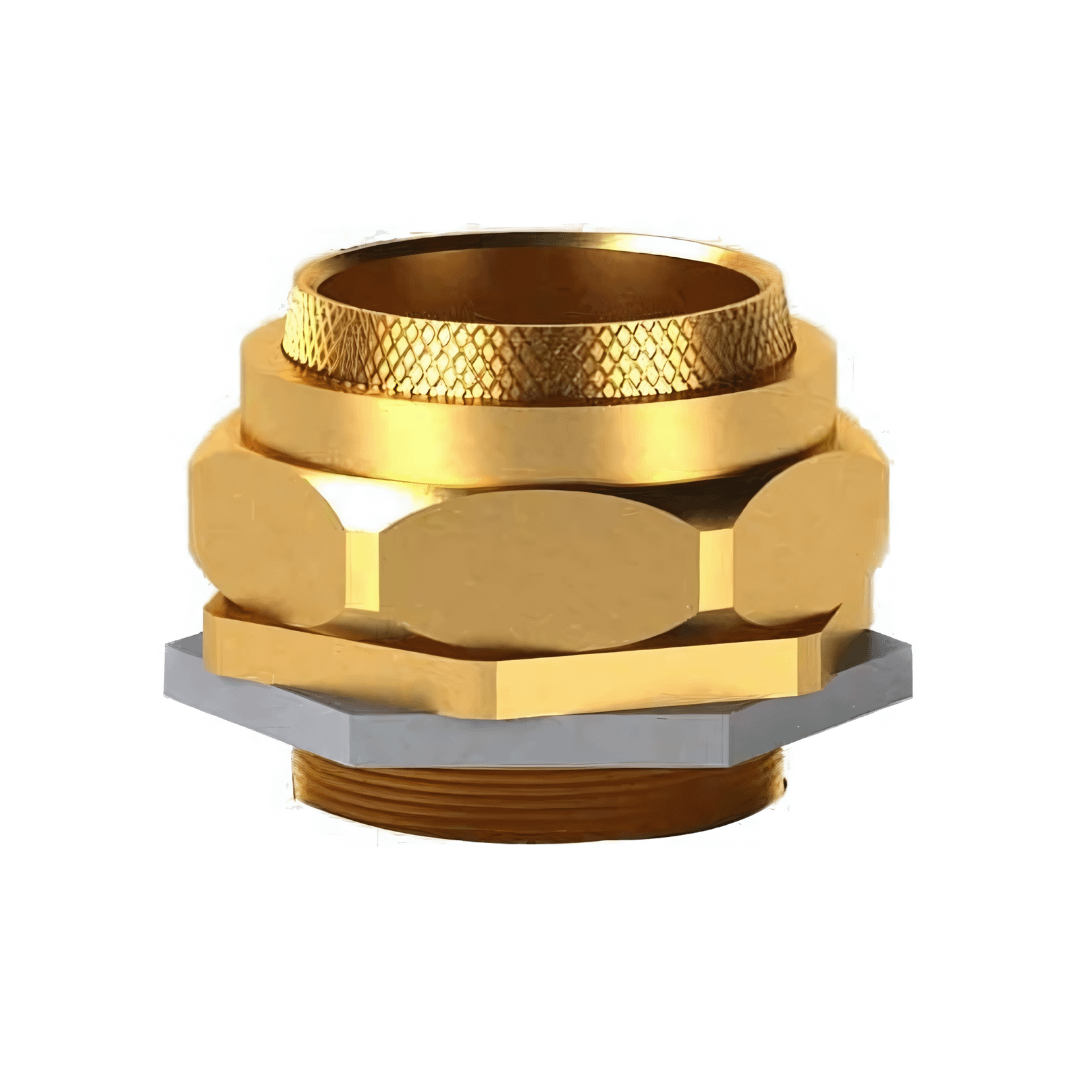

In the world of electrical engineering, a cable gland is much more than a simple connector. It is a critical safety device designed to provide strain relief, sealing, and grounding for electrical cables.

When it comes to high-stakes environments—ranging from oil refineries to renewable energy plants—Brass Cable Glands are the preferred choice. Here is an in-depth look at why brass remains the superior material for cable management and why sourcing from Jamnagar is the strategic choice for Indian businesses.

What Makes Brass the Ideal Material for Cable Glands?

While plastic (nylon) and stainless steel glands exist, brass occupies the most versatile position in the industry due to its unique mechanical properties.

- Superior Mechanical Strength: Brass glands can withstand significant physical impact and mechanical stress without cracking, unlike plastic alternatives.

- EMI/RFI Shielding: Brass is naturally conductive, making it excellent for Electromagnetic Interference (EMI) shielding—a must-have for sensitive data and power cables.

- Environmental Resilience: Brass thrives in extreme temperatures and is highly resistant to the corrosive effects of moisture and industrial chemicals.

- Longevity: A brass cable gland is a “fit and forget” solution, often outlasting the equipment it is installed on.

Read Also: Brass Cable Glands by BOLTORQ Brassmet: A Comprehensive Guide

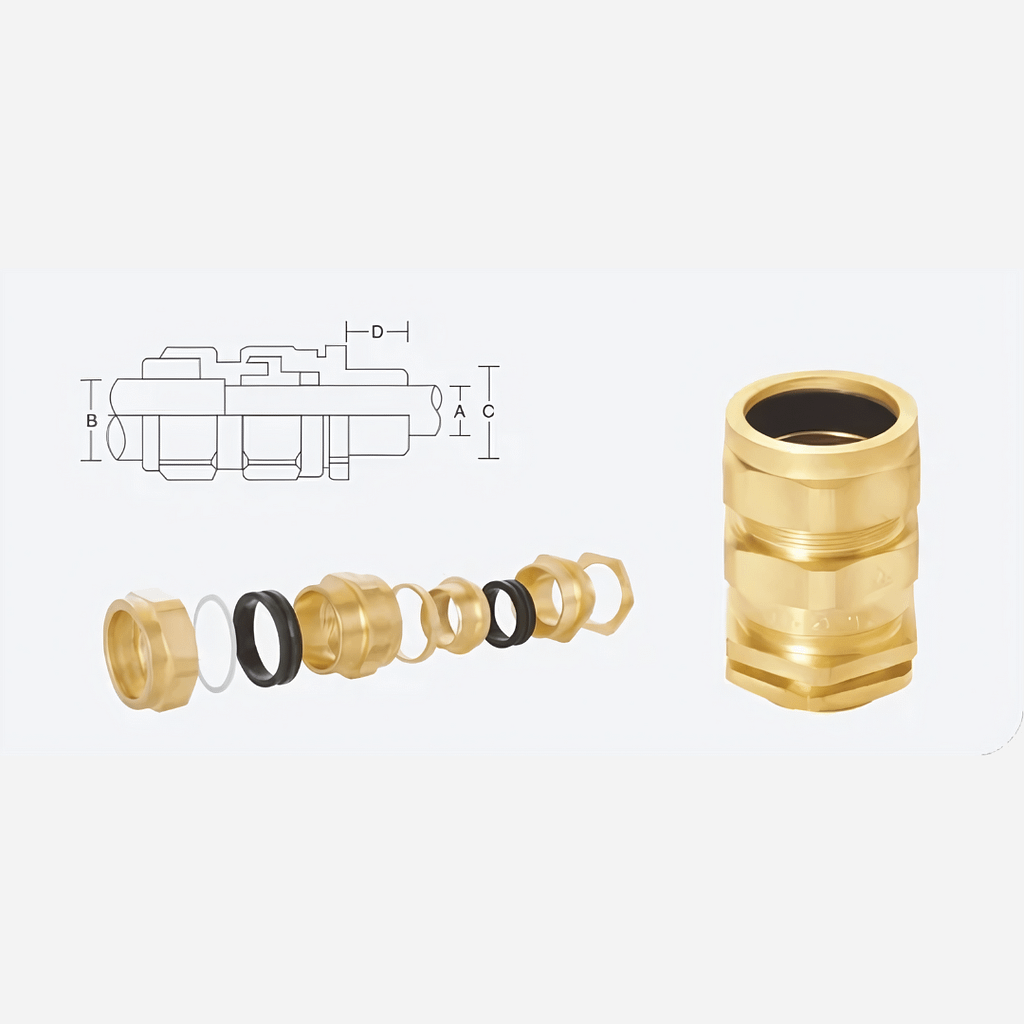

Types of Brass Cable Glands and Their Applications

Choosing the right gland depends on the environment and the cable type (Armoured vs. Unarmoured).

| Gland Type | Application | Key Feature |

| A2 Glands | Unarmoured Cables | Ideal for indoor/outdoor use where a basic seal is needed. |

| BW Glands | Armoured Cables (SWA) | Used in dry, indoor conditions to provide mechanical cable retention. |

| CW Glands | Armoured Cables (Outdoor) | Provides a dual seal (outer and inner) for waterproof protection. |

| E1W Glands | Heavy-Duty Outdoor | Features a weatherproof seal and an extra layer of protection for the cable armour. |

The Jamnagar Manufacturing Advantage

As a professional in the Indian market, sourcing your brass cable glands from Jamnagar gives you a distinct competitive edge. Jamnagar is globally recognized for its precision-turned brass components.

By partnering with a manufacturer like Boltorq BrassMet, you ensure that your cable glands meet the rigorous IP66, IP67, and IP68 ingress protection ratings. This ensures your electrical enclosures remain dust-tight and protected against powerful water jets or immersion.

Secure Your Infrastructure with Boltorq BrassMet

At Boltorq BrassMet, we understand that electrical failure is not an option. Our brass cable glands are engineered for precision and safety.

Why choose Boltorq BrassMet?

- Precision Threading: Available in Metric, NPT, and BSP threads for a perfect fit.

- High-Quality Plating: We offer Nickel and Chrome plating for enhanced corrosion resistance in marine and chemical environments.

- Compliance: Our parts are designed to meet international safety and quality standards, ensuring your projects are audit-ready.

Frequently Asked Questions

Can brass cable glands be used in hazardous (Ex) areas?

Yes, but they must be specifically certified as “Flameproof” or “Increased Safety” (ATEX/IECEx). Always check the certification before installing in explosive atmospheres.

Is nickel plating necessary for brass glands?

While natural brass is corrosion-resistant, nickel plating provides an extra layer of protection against oxidation and chemical wear, especially in coastal or offshore environments.

What is the difference between an indoor and outdoor cable gland?

Indoor glands (like BW) focus on mechanical grip, while outdoor glands (like CW or E1W) include rubber seals to prevent moisture from entering the cable and the electrical box.

1 Comment

Precision Brass Parts: The Backbone of Modern Engineering - BOLTORQ Brassmet Industries · February 10, 2026 at 5:04 am

[…] Read Also: Why Brass Cable Glands are the Gold Standard for Industrial Wiring Safety […]