Regular Inspection of Brass Fittings in Industrial Plumbing Systems

Why Brass Fittings Demand Proactive Inspection

Industrial plumbing systems in manufacturing, chemical plants, oil & gas facilities, and water treatment units depend heavily on precision brass fittings for safe, leak‑free operations. Regular inspection of brass pipe couplings, valve brass components, and plumbing pipes and fittings is critical to prevent sudden failures, downtime, and safety incidents in high‑pressure and high‑temperature environments.

What Makes Brass Fittings Ideal for Industrial Plumbing?

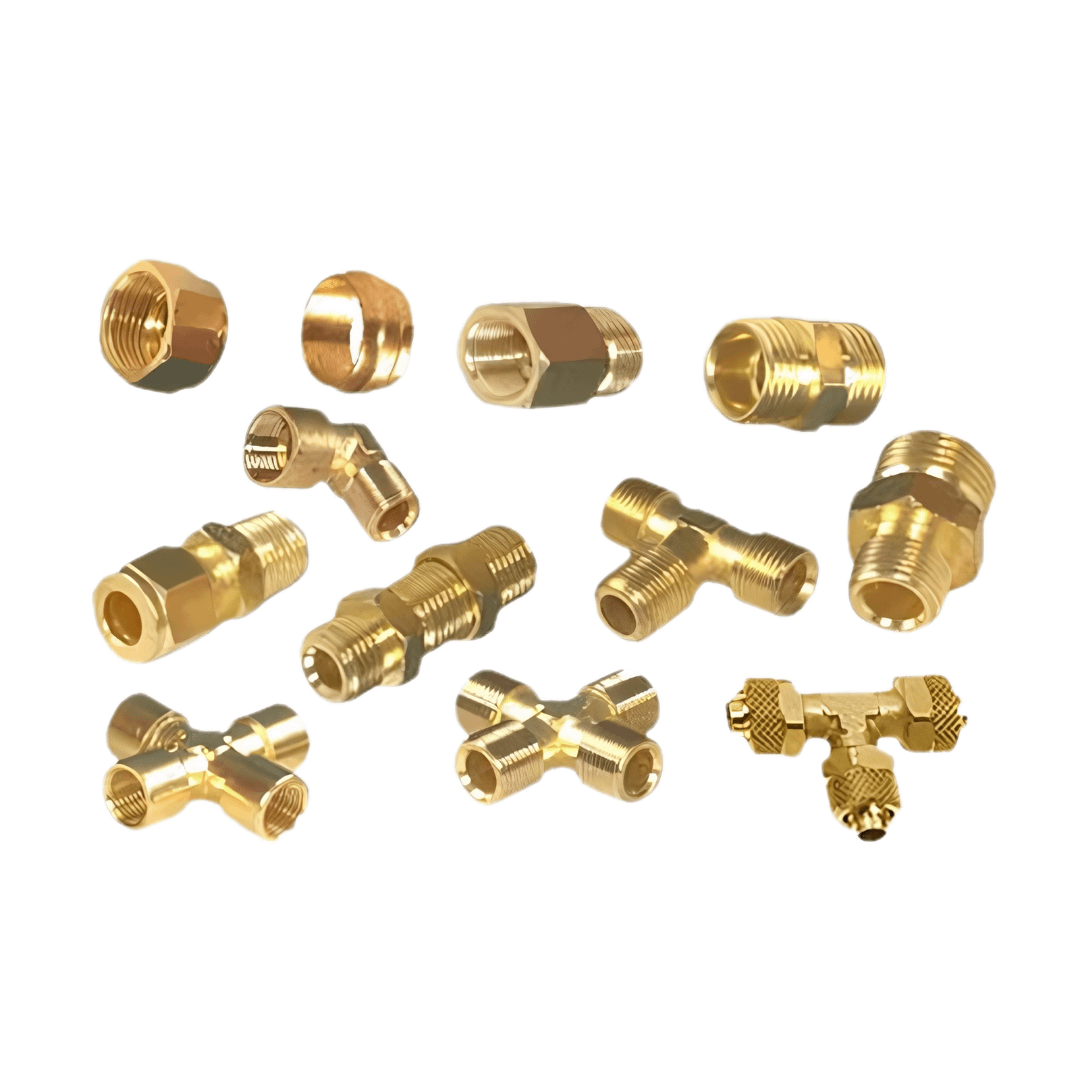

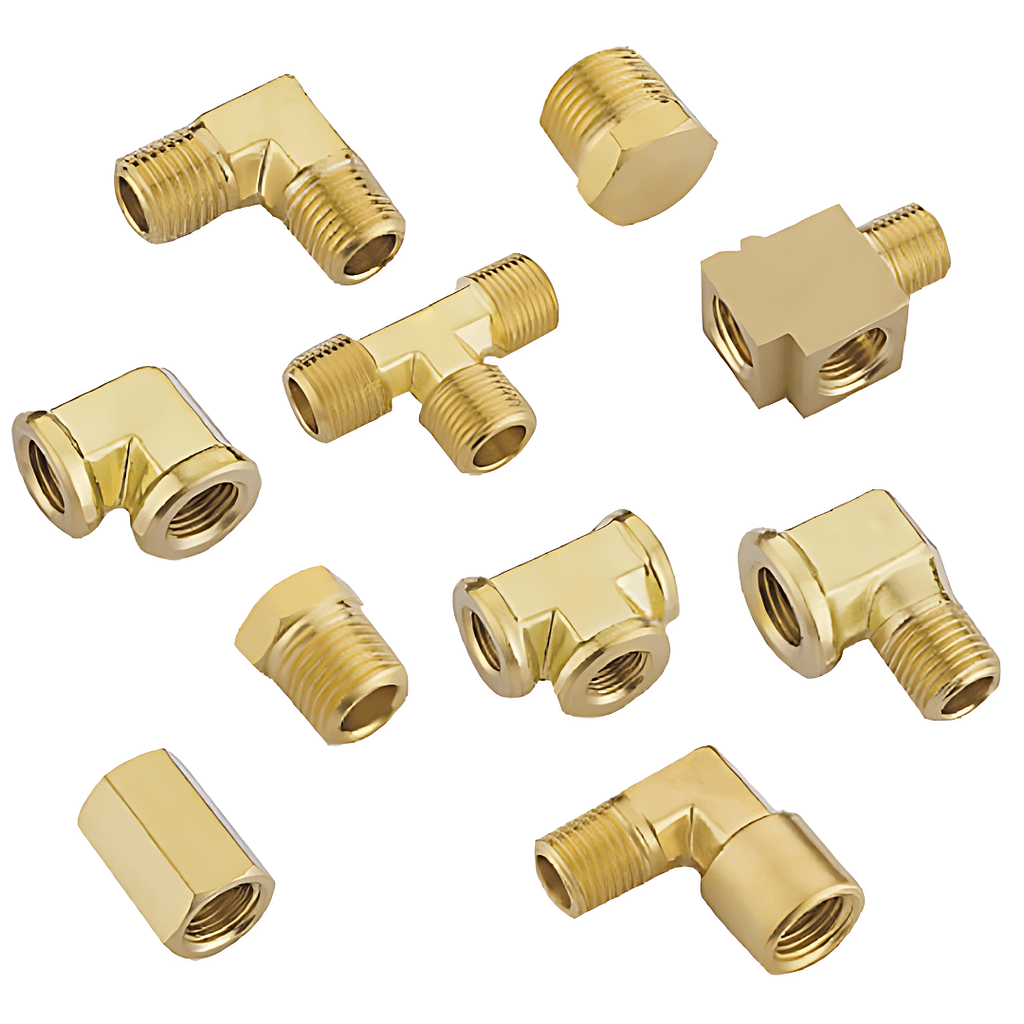

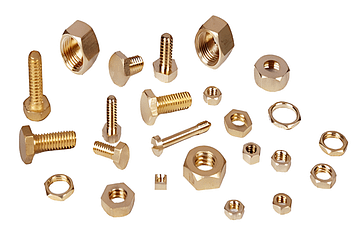

Brass is a copper‑zinc alloy known for its excellent machinability, corrosion resistance, and strength, which makes it a preferred material for industrial brass fittings and couplings. Common brass components in industrial plumbing systems include elbows, tees, unions, reducers, adapters, and brass pipe couplings used to connect complex pipe networks.

- Corrosion resistance: Brass offers strong resistance to rust and many industrial fluids, making it suitable for aggressive and humid environments.

- High‑temperature and pressure capability: Brass fittings can handle significant thermal and pressure loads, which is essential in steam lines, compressed air systems, and process pipelines.

- Precision machinability: High machinability allows precision brass components with tight tolerances, ensuring reliable sealing and repeatable assembly in industrial installations.

Why Regular Inspection of Brass Fittings Is Non‑Negotiable

Even high‑quality brass fittings and couplings degrade over time due to mechanical stress, vibration, temperature cycling, fluid chemistry, and installation errors. Skipping routine inspections increases the risk of leaks, unplanned shutdowns, and safety non‑compliance in industrial setups.

Key consequences of poor or irregular inspection:

- Hidden leaks leading to pressure drops and reduced system efficiency.

- Localized corrosion or dezincification that weakens industrial brass components over time.

- Pipe bursts or catastrophic failures in high‑pressure sections.

- Contamination of process fluids or gases, especially in chemical and food applications.

Proactive inspections of brass plumbing fittings transform maintenance from reactive firefighting to planned reliability management.

Critical Areas to Inspect in Industrial Brass Fitting Networks

Not all sections of an industrial plumbing system carry the same risk; some zones require more frequent and detailed inspection of brass plumbing pipes and fittings. Focusing on high‑stress, high‑exposure, and high‑consequence areas ensures better reliability with less effort.

Key inspection points:

- Joint connections: Interfaces where brass pipe couplings join two lines are prime locations for leaks, stress concentration, and misalignment.

- Valve brass assemblies: Seats, stems, bodies, and connections in valve brass components control flow and pressure and are critical for safety and process control.

- Threaded fittings and adapters: Threads are prone to loosening, galling, and seal failure, especially under vibration.

- Corrosion‑prone zones: Areas exposed to chemicals, salt‑laden air, moisture, or cleaning agents need closer monitoring for dezincification and pitting in brass fittings.

Recommended Inspection Frequency for Brass Fittings

Inspection intervals depend on process severity, media handled, temperature, and pressure, but industrial best practice is to treat brass fittings as safety‑critical components rather than consumables. Regular, documented inspection programs help facilities comply with internal standards and external regulations.

Suggested guidelines:

- Standard industrial services (water, air, non‑corrosive fluids): Inspect brass plumbing fittings every 12 months or during annual shutdowns.

- High‑pressure or high‑temperature lines: Shorten intervals to 6 months, with targeted checks on valves and couplings.

- Corrosive or aggressive media: Inspect every 3–6 months and combine visual checks with non‑destructive testing where failure risk is high.

Inspection Methods and Tools for Brass Fitting Integrity

An effective inspection program combines simple visual checks with more advanced diagnostic techniques to detect early damage in industrial brass fittings. Selecting the right tools and methods depends on system complexity, safety class, and accessibility.

Core inspection methods:

- Visual inspection: Look for discoloration, surface corrosion, cracks, seepage marks, and deformed threads on brass components and couplings.

- Pressure testing: Hydrostatic or pneumatic testing simulates operating conditions to reveal leaks or weak joints in brass pipe couplings and valves.

- Ultrasonic or radiographic testing: Useful for detecting internal flaws, wall thinning, or hidden cracks in critical sections without dismantling.

- Torque verification: Checking torque on threaded brass fittings ensures correct clamping and reduces the risk of loosening under vibration.

Benefits of Regular Inspection of Brass Plumbing Fittings

A structured maintenance and inspection routine for brass fittings and valves delivers measurable operational and financial benefits. Investing time in inspection directly pays back through improved uptime, safety, and asset life.

Key advantages:

- Prevention of unplanned downtime: Detecting early leakage or weakening avoids emergency shutdowns during peak production.

- Extended service life of brass components: Identifying wear, dezincification, and thread damage early allows timely replacement or repair.

- Improved energy and process efficiency: Tight, leak‑free systems maintain design pressure and flow, cutting energy consumption and product loss.

- Better safety and regulatory compliance: Documented inspections and maintenance records help demonstrate adherence to safety standards.

Common Challenges in Inspecting Brass Fittings – And How to Overcome Them

Industrial environments often make brass fitting inspections difficult due to accessibility constraints, production pressure, and documentation gaps. Overcoming these barriers is essential to sustain a high‑reliability culture.

Typical challenges:

- Limited access to fittings inside congested pipe racks or enclosed skids.

- Reluctance to shut down critical lines for detailed inspection or replacement.

- Incomplete or outdated records of previous inspections, torque values, or component changes.

- Minor issues such as hairline cracks or micro‑leaks getting overlooked under time pressure.

Practical solutions:

- Plan inspection routes with 3D models and layout drawings to prioritize high‑risk zones.

- Combine inspections with scheduled turnarounds or planned maintenance windows to minimize disruption.

- Implement digital logging for brass fitting inspection records, including dates, findings, and actions taken.

- Use portable NDT tools and leak detectors to quickly scan large networks of brass plumbing pipes and fittings.

Maintenance Best Practices After Inspection

Inspection is only effective when findings lead to timely corrective actions on brass couplings, valves, and fittings. Structured post‑inspection maintenance ensures that identified risks are resolved before they escalate into failures.

Recommended best practices:

- Replace worn, cracked, or heavily corroded brass pipe couplings and fittings immediately rather than deferring.

- Retighten or reseal threaded joints using appropriate sealants or tapes compatible with the service media.

- Apply corrosion‑resistant coatings or sleeves where fittings are exposed to aggressive atmospheres or splashes.

- Lubricate moving parts in valve brass assemblies as per manufacturer guidelines to reduce wear and sticking.

- Standardize inspection and maintenance intervals across departments to ensure consistency and traceability.

How Boltorq BrassMet Supports Reliable Brass Fitting Performance

As a specialized manufacturer of brass construction parts, brass plumbing fittings, and industrial brass components, Boltorq BrassMet partners with plant teams to improve both product selection and lifecycle performance. Precision‑machined brass couplings, adapters, and valve components are designed for demanding industrial conditions and undergo strict quality checks before dispatch.

Support offered to industrial users and OEMs includes:

- Application engineering help to select the right brass fittings and pipe couplings for pressure, media, and temperature conditions.

- Guidance on installation practices, torque recommendations, and sealant compatibility for brass plumbing pipes and fittings.

- Assistance in building inspection checklists and maintenance plans tailored to specific plants or process units.

- Capability to supply custom and CNC‑machined brass components for retrofits, upgrades, and high‑reliability applications.

By aligning product design with robust maintenance practices, Boltorq BrassMet helps industrial facilities achieve safer, more efficient, and longer‑lasting plumbing systems built around high‑performance brass fittings.

FAQs on Regular Inspection of Brass Fittings in Industrial Setups

How often should industrial brass fittings be inspected?

Inspection frequency depends on service conditions, but most industrial setups benefit from checking brass plumbing fittings at least every 6–12 months, with more frequent checks in corrosive or high‑pressure services.

What are early warning signs of brass fitting failure?

Common signs include dampness or staining around joints, pressure loss, visible corrosion or discoloration, distorted threads, and difficulty operating valve brass components.

Is visual inspection alone enough for brass fittings?

Visual checks are essential but may not reveal internal defects, so critical lines should also use pressure testing and, where justified, ultrasonic or radiographic methods.

What happens if brass fittings are not inspected regularly?

Lack of regular inspection increases the chances of sudden leaks, bursts, fluid contamination, environmental incidents, and costly unplanned shutdowns.

Are all brass fittings corrosion‑resistant in industrial environments?

Brass offers good general corrosion resistance, but factors such as fluid chemistry, temperature, and dezincification risk mean not all brass fittings behave identically in every service, so proper alloy selection and inspection are essential.

0 Comments