Why Brass is the Ultimate Choice for Precision Smoking Accessories

In the world of premium lifestyle accessories, the material is just as important as the design. While glass and silicone have their place, brass smoking parts have stood the test of time, evolving from traditional cultural artifacts to modern, precision-engineered components.

Whether you are a wholesaler in Delhi’s busy markets or an export house in Moradabad, understanding the “why” behind brass is essential for anyone in the high-end metalware industry.

Why Brass? The Science of a Superior Session

Brass isn’t just chosen for its royal golden hue. As an alloy of copper and zinc, it offers a unique set of physical properties that make it safer and more durable than cheaper alternatives like aluminum or “pot metal” (zinc alloys).

1. Thermal Management & Even Heating

One of the biggest advantages of brass is its heat resistance. Unlike aluminum, which can overheat quickly and affect the flavor profile, brass distributes heat evenly. This prevents the component from warping and ensures a consistent experience for the user.

2. Natural Antimicrobial Properties

Inherited from its copper content, brass possesses a natural oligodynamic effect. It can neutralize many pathogens on its surface within hours—a critical hygiene benefit for accessories that are handled frequently.

3. Rugged Durability

Glass breaks. Silicone tears. Brass lasts a lifetime. For travelers and outdoor enthusiasts, a brass component is virtually indestructible, making it a “buy it once” investment.

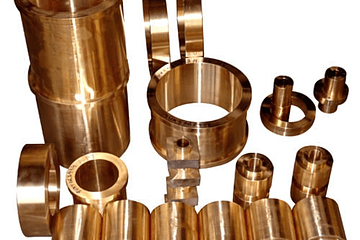

The Anatomy of High-Quality Brass Smoking Components

| Part Type | Manufacturing Process | Key Requirement |

| Precision Chillums | CNC Turning | Mirror-smooth internal bore |

| Metal Pipe Stems | Threading & Boring | Air-tight seals and high-grade threads |

| Custom Grinders | Diamond-cut Milling | Razor-sharp teeth & friction-free rotation |

| Screen Filters | Fine Mesh Stamping | Heat-resistant & non-corrosive |

“In the heart of Moradabad’s industrial clusters, the transition from traditional sand casting to high-precision CNC machining has redefined what ‘export-quality’ means for the global smoking accessory market.”

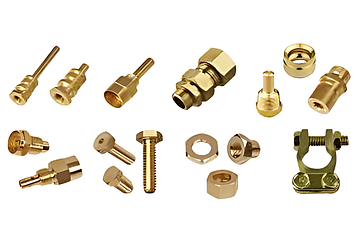

The Indian Manufacturing Edge

India—specifically Jamnagar (The Brass Capital of India)—is the global epicenter for high-quality brassware. By combining centuries-old metalworking heritage with modern CNC (Computer Numerical Control) technology, Indian manufacturers like Boltorq Brassmet are producing parts that meet the strict tolerances required by international luxury brands.

Why Source from India?

- Customization: Ability to create bespoke designs via CNC Swiss machining.

- Lead-Free Alloys: Compliance with international safety standards (RoHS/REACH).

- Cost-Efficiency: Competitive wholesale pricing without compromising on the weight and “feel” of premium brass.

Frequently Asked Questions

Does brass affect the flavor of smoking accessories?

High-quality, medical-grade brass is non-reactive. Unlike cheaper plated metals, solid brass does not peel or release harmful fumes when heated, preserving the purity of the experience.

How do you clean brass smoking parts?

Because brass is non-porous and rugged, it can be cleaned with a simple solution of isopropyl alcohol and salt, or traditional lemon and salt for a polished shine.

Is brass better than stainless steel?

While both are durable, brass is often preferred for its classic aesthetic, superior machinability for intricate designs, and its natural antimicrobial properties.

The Future is Precision

As the global market shifts toward sustainable and long-lasting products, the demand for metal-based lifestyle accessories is skyrocketing. For businesses looking to scale, the focus must remain on material purity and engineering precision.

If you are ready to elevate your inventory with components that define durability and class, exploring the world of brass smoking parts is your next logical step. From design to delivery, quality brass engineering is what separates the leaders from the rest.

0 Comments