The Vital Role of Brass Auto Parts: Why Jamnagar Leads the Indian Automotive Supply Chain

In the high-stakes world of automotive engineering, the choice of material isn’t just a technical detail—it’s a performance mandate. Among the various alloys used in modern vehicle manufacturing, brass stands out as an unsung hero. From the bustling industrial lanes of Jamnagar, Gujarat, to global assembly lines, brass auto parts are the backbone of vehicle reliability.

Whether you are an OEM procurement manager or an automotive enthusiast, understanding the specific use cases of brass components is essential for optimizing vehicle lifespan and safety.

Why Brass? The Engineering Edge

Before diving into specific applications, it is important to understand why the automotive industry prefers brass over aluminum or steel in critical zones.

- Corrosion Resistance: Unlike steel, brass does not rust. It withstands exposure to road salt, moisture, and engine fluids.

- High Thermal Conductivity: Essential for heat exchange systems, brass dissipates heat faster than many alternative metals.

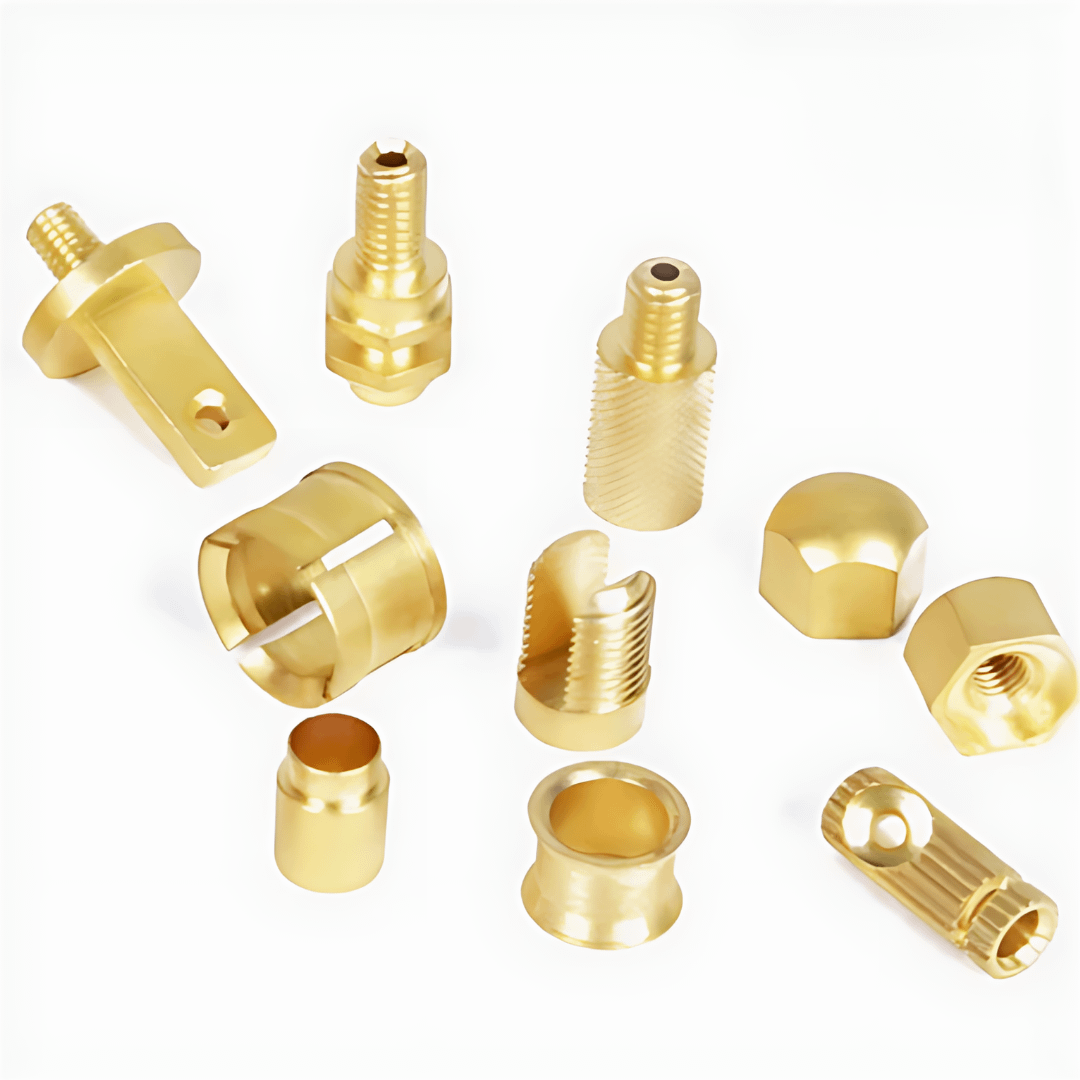

- Superior Machinability: Brass can be precision-machined into complex shapes (like sensor housings and micro-terminals) with micron-level accuracy.

- Durability and “Seating”: In plumbing and fuel lines, brass is soft enough to create a perfect, leak-proof seal but hard enough to withstand high pressure.

Key Use Cases of Brass Auto Parts

1. Fuel and Gas Systems

Precision is non-negotiable in fuel delivery. Brass fuel nozzles, fittings, and connectors are used because they are non-sparking and resistant to the chemical degradation caused by modern fuels and additives.

- Components: Fuel injectors, banjo parts, and gas regulators.

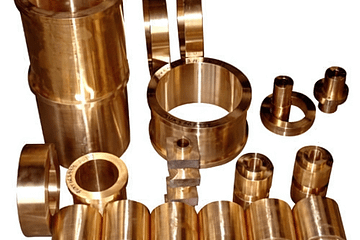

2. Cooling and Heat Exchange

Because of its excellent thermal properties, brass has been a legacy material for radiator cores and heater cores. While aluminum is used for weight reduction in some areas, brass remains the choice for heavy-duty radiators and high-pressure tanks due to its ability to be easily repaired and its resistance to “fatigue.”

- Components: Radiator valves, thermostats, and coolant sensor housings.

3. Electrical and Sensor Components

Modern vehicles are essentially computers on wheels. Brass provides the electrical conductivity needed for stable signal transmission without the high cost of silver or the oxidation issues of copper.

- Components: Battery terminals, spark plug connectors, and temperature sensor bodies.

4. Braking and Hydraulic Systems

Hydraulic systems operate under extreme pressure. Brass brake line fittings and valves ensure that the hydraulic fluid remains contained without leaking, even under the stress of emergency braking.

- Components: Brake connectors, hydraulic sleeves, and air brake fittings.

Jamnagar: The “Brass City of India” Hub

If you are sourcing brass auto parts in India, all roads lead to Jamnagar. As the global hub for brass manufacturing, Jamnagar houses over 5,000 units specializing in precision-turned components.

| Feature | Why Source from Jamnagar? |

| Manufacturing Scale | Over 60% of India’s brass components originate here. |

| Technology | State-of-the-art CNC and VMC machining facilities for tight tolerances. |

| Compliance | Most exporters follow ISO 9001, RoHS, and REACH standards. |

| Cost-Efficiency | Integrated ecosystem from foundries to plating units reduces lead times and costs. |

Choosing the Right Manufacturer in India

When searching for a partner in the Indian market, look for manufacturers who provide:

- Material Certification: Ensure the brass alloy (e.g., C36000 or CZ121) matches your technical requirements.

- Surface Finishing: Options like Nickel, Tin, or Chrome plating for added wear resistance.

- Customization: The ability to manufacture parts based on specific CAD drawings or OEM samples.

Pro Tip: For buyers in Jamnagar, visiting the GIDC (Gujarat Industrial Development Corporation) zones is the best way to vet suppliers and witness the quality control processes firsthand.

Partner with Excellence: Boltorq BrassMet

When quality and precision cannot be compromised, you need a manufacturing partner that understands the nuances of the automotive industry.

At Boltorq BrassMet, we specialize in high-precision brass components that meet the rigorous demands of Indian and international automotive standards. Based in the heart of Jamnagar, we combine traditional craftsmanship with modern CNC technology to deliver parts that drive performance.

The Future: Electric Vehicles (EVs) and Brass

The shift to EVs isn’t making brass obsolete; it’s changing its role. EVs require more sensors, complex busbars, and high-voltage connectors—all of which rely on the unique conductivity and durability of brass alloys.

0 Comments