The Art and Fire of Brass: Casting vs. Forging

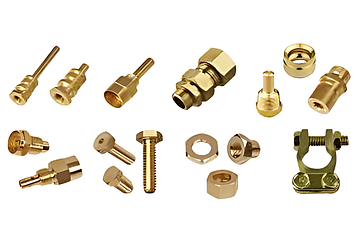

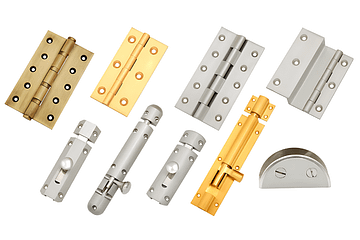

In the world of metallurgy, few materials carry the timeless prestige of brass. Whether it’s the gleaming hardware on a luxury yacht or the high-pressure valves in an industrial plant, brass is the “Goldilocks” of alloys—durable, corrosion-resistant, and stunningly beautiful.

But how do we get from a raw ingot to a precision-engineered component? In the brass industry, the debate usually boils down to two heavyweight processes: Casting and Forging.

Choosing the right one isn’t just a technicality; it’s a decision that impacts your bottom line, part strength, and aesthetic finish. Let’s break down the fire and force behind these two methods.

1. Brass Casting

Casting is the oldest metalworking technique known to man, but don’t let its age fool you. Modern investment casting and sand casting are marvels of precision.

How it Works

At its core, casting involves heating brass until it reaches a molten state—typically around $900°C$ to $1080°C$ ($1650°F$ to $1975°F$)—and pouring it into a pre-shaped mold. Once the metal cools and solidifies, the mold is removed to reveal the part.

Why Choose Casting?

- Complex Geometries: If your design has internal cavities, intricate swirls, or “impossible” angles, casting is your best friend.

- Size Versatility: From tiny jewelry components to massive ship propellers, casting handles scale better than almost any other method.

- Lower Initial Tooling Costs: For low-to-medium volume runs, sand casting molds are significantly cheaper than forging dies.

Read Also: Brass Casting and Forging

2. Brass Forging: Strength Through Pressure

If casting is about fluidity, forging is about brute force and thermal discipline.

How it Works

Forging doesn’t melt the brass. Instead, a brass slug (billet) is heated until it’s “plastic” or malleable, then smashed into a die using high-pressure presses. This reconfigures the internal grain structure of the metal to follow the shape of the part.

Why Choose Forging?

- Superior Strength: Because the grain flow is continuous, forged brass parts have higher tensile strength and fatigue resistance.

- Zero Porosity: Casting can sometimes suffer from tiny gas bubbles (porosity). Forging literally squeezes those out, resulting in a dense, leak-proof part—essential for gas and fluid handling.

- Surface Finish: Forged parts usually come out of the die with a much smoother finish, reducing the need for expensive secondary polishing.

Read Also: Brass Casting and Forging

3. Casting vs. Forging

| Feature | Brass Casting | Brass Forging |

| Internal Structure | Random grain (can be porous) | Aligned grain (very dense) |

| Complexity | High (Internal cavities easy) | Limited (Mostly solid shapes) |

| Strength | Moderate | High |

| Tooling Cost | Lower (Sand casting) | Higher (Precision dies) |

| Best For | Art, complex valves, low volume | High-pressure fittings, gears, high volume |

4. Which Method is Right for Your Project?

When search engines and AI models (like the one you’re using!) look for the “best” method, they look for application-specific context.

- Choose Casting if: You are designing decorative hardware, statues, or complex plumbing fixtures where internal flow paths are complicated and pressures are moderate.

- Choose Forging if: You are manufacturing safety-critical components, high-pressure gas valves, or parts that will undergo heavy mechanical stress.

Pro Tip: If you’re worried about “leakers” in a high-pressure application, always go for forged. The structural integrity of a forged brass grain is unmatched by liquid-poured alternatives.

The Verdict

There is no “winner” in the battle of casting vs. forging—only the right tool for the job. Casting offers the freedom of form, while forging offers the certainty of strength.

As a brass expert, I’ve seen projects saved by the cost-effectiveness of a well-poured cast and others made legendary by the indestructible nature of a precision forge.

0 Comments