Precision & Hygiene: The Critical Role of Brass Medical Parts in 2026

In the modern healthcare landscape, the difference between a successful procedure and a medical complication often hinges on the quality of the smallest components. While high-tech software and robotics garner headlines, the foundational hardware—specifically brass medical parts—remains the unsung hero of the operating room.

“The antimicrobial properties of copper-based alloys like brass are no longer just a benefit; they are a standard in the fight against hospital-acquired infections (HAIs).” — Industry Insights 2026

Why Brass is the Gold Standard for Medical Components

Medical device manufacturers prioritize materials that offer a balance of machinability, durability, and biological safety. Brass, an alloy of copper and zinc, excels in all three.

Key Benefits of Brass in Healthcare:

- Antimicrobial Efficacy: Brass surfaces naturally kill 99.9% of bacteria within two hours of contact.

- Corrosion Resistance: Essential for components exposed to bodily fluids and harsh sterilization chemicals.

- Non-Magnetic Nature: Critical for parts used in proximity to MRI machines and sensitive diagnostic imaging.

- High Precision Machining: Brass allows for extremely tight tolerances ( +- 0.0001 inches), vital for surgical nozzles and valves.

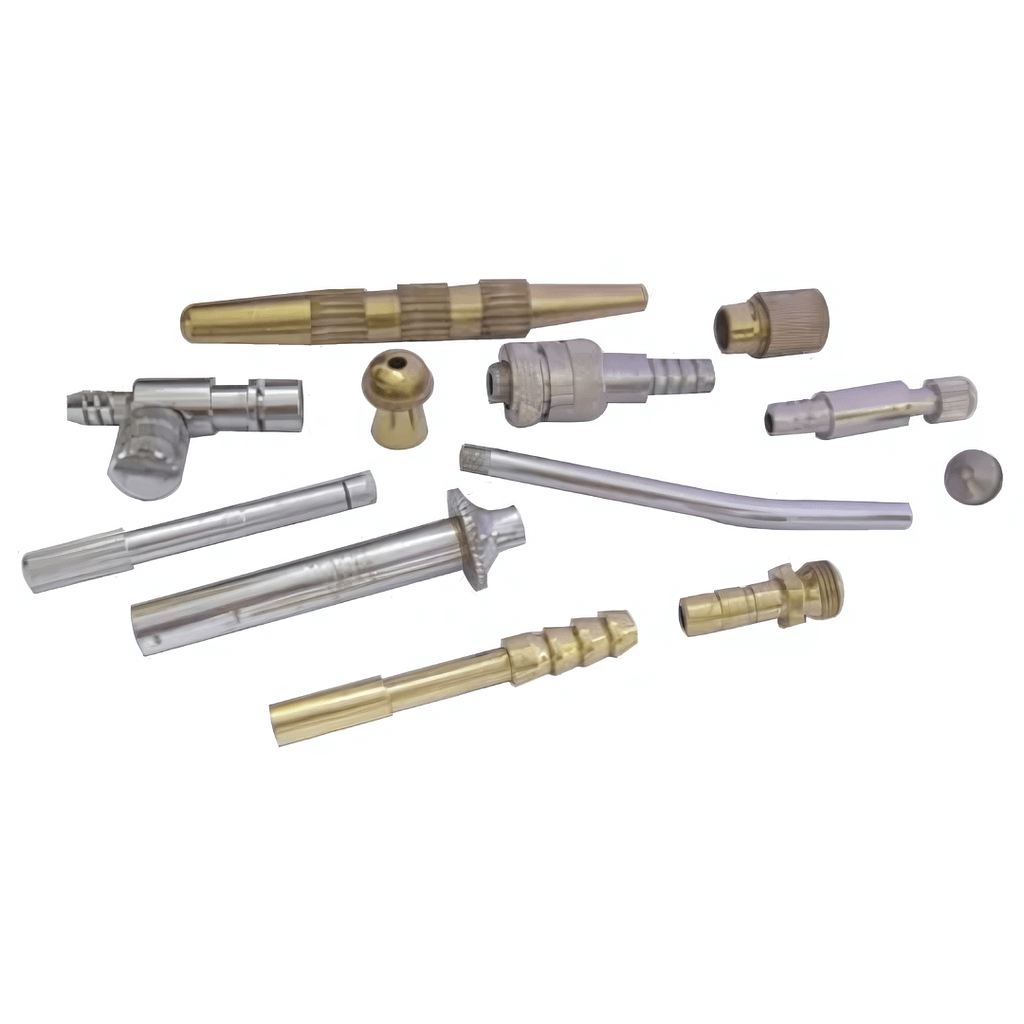

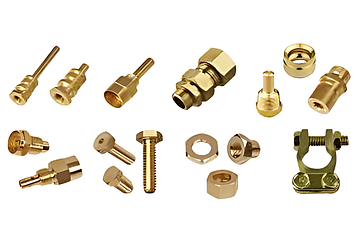

Common Applications of Brass Medical Parts

From life-saving respiratory equipment to surgical instruments, brass is integrated into various medical technologies.

| Component Type | Primary Application | Key Feature |

| Oxygen Flow Meter Parts | Respiratory Support | Gas-tight sealing & durability |

| Surgical Nozzles & Valves | Precision Fluid Control | Corrosion-free performance |

| Diagnostic Connectors | Imaging (MRI/CT Scanners) | Non-magnetic & high conductivity |

| Dental Handpiece Parts | Dentistry | Lightweight & high-speed stability |

The Lead-Free Revolution

As global health regulations tighten, the shift toward Low-Lead and Lead-Free Brass Alloys has become a primary market driver. Modern manufacturing processes, such as CNC Swiss Machining, allow for the creation of intricate parts that meet both FDA and EU medical device standards without compromising on structural integrity.

Frequently Asked Questions

Is brass safe for internal medical use?

Brass is primarily used for external instruments, fluid handling systems, and diagnostic equipment. While it is biocompatible for short-term contact, internal implants typically utilize titanium or specialized stainless steel.

How does brass contribute to hospital hygiene?

Brass is a copper-based alloy. Copper ions create oxidative stress in bacteria, destroying their DNA and preventing the spread of germs on touch surfaces and equipment handles.

Can brass parts be sterilized repeatedly?

Yes. High-quality brass components are designed to withstand autoclaving and chemical sterilization without degrading or losing dimensional accuracy.

The Future of Medical Manufacturing

As we look toward 2030, the integration of Industry 4.0 and smart manufacturing is allowing for even greater customization of medical hardware. The demand for reliable, antimicrobial, and cost-effective materials ensures that brass will remain a cornerstone of medical engineering for decades to come.

Whether you are designing the next generation of ventilators or upgrading surgical hardware, choosing the right manufacturing partner is essential for maintaining patient safety and regulatory compliance.

For those seeking high-precision engineering and export-quality reliability, exploring specialized brass medical parts is the first step toward superior performance in the healthcare sector.

0 Comments