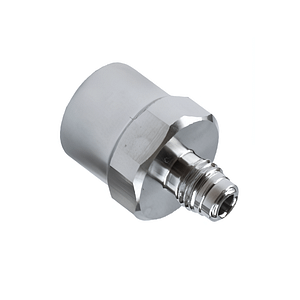

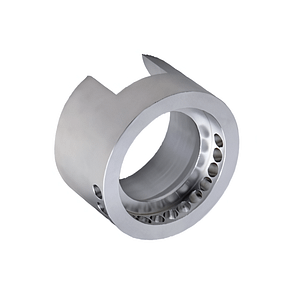

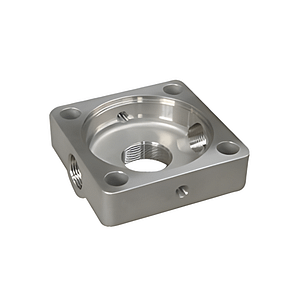

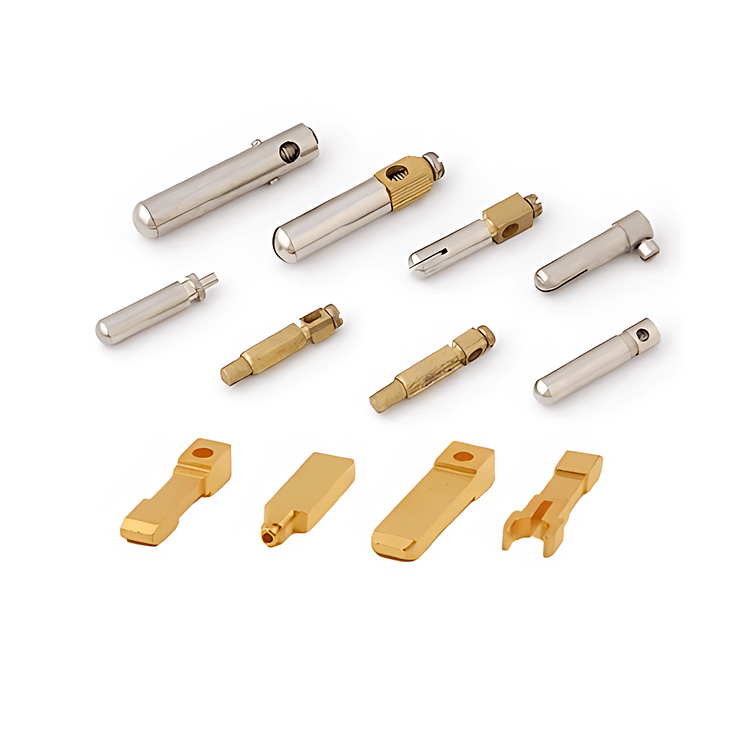

CNC Machining Parts for Precision Manufacturing

CNC machining parts are precision components produced using computer numerical control machines that follow digital instructions to cut, mill, turn and shape materials into exact specifications. These parts serve automotive, aerospace, electronics, medical, industrial and consumer applications requiring tight tolerances and repeatable quality.

Precision Engineering and Tight Tolerances

CNC machining delivers exceptional dimensional accuracy through automated tool paths and control systems. Key capabilities include:

- Tolerances to ±0.01mm or better for critical features

- Complex 3D contours, undercuts and internal geometries

- Consistent quality across prototypes to high-volume production

- Multi‑axis machining (3, 4, 5‑axis) for single‑setup complexity

This precision eliminates manual errors and supports assemblies where fit and function are critical.

Versatile Material Compatibility

CNC machines process a broad range of engineering materials:

- Metals: Brass, stainless steel, aluminum, titanium, copper alloys

- Plastics and composites: Delrin, nylon, PEEK, carbon fiber, acrylic

- Exotics: Tool steels, Inconel, Hastelloy for extreme conditions

Material selection matches mechanical, thermal, corrosion and electrical requirements of each application.

Complex Geometries in Single Operations

Unlike traditional methods, CNC machining creates intricate features efficiently:

- Internal and external threads, splines and helical features

- Cross holes, ports and intersecting passages

- Thin walls, ribs and micro‑details

- Surface finishes from rough stock removal to mirror polishing

Multi‑tool operations reduce setups, improve accuracy and lower per‑part costs.

Production Efficiency and Scalability

Once programmed, CNC machining offers:

- 24/7 unattended operation for high productivity

- Quick changeovers between part numbers

- Programming reuse for design revisions and repeat orders

- Scalable capacity from one‑offs to 100,000+ piece runs

Automation reduces labor costs while maintaining precision across volumes.

Cost‑Effective for Prototypes and Production

CNC machining balances upfront programming costs with per‑part efficiency:

- No expensive tooling for low to medium volumes

- Rapid iteration for design validation and optimization

- Flexible response to engineering changes

- Competitive economics versus casting or molding for complex parts

Optimal for bridge production, custom components and market testing.

Customization from Customer Specifications

CNC machining supports full customization:

- Parts produced directly from STEP files, drawings or 3D models

- Secondary operations: plating, heat treatment, assembly

- First article inspection (FAI) and SPC quality control

- Reverse engineering from physical samples

Tailored solutions for OEMs, contract manufacturers and R&D projects.

Conclusion

CNC machining parts provide unmatched precision, material versatility and production flexibility for modern engineering applications. From prototype development to high‑volume manufacturing, CNC machining delivers complex, high‑quality components that meet exacting dimensional and performance requirements across automotive, aerospace, medical, electronics and industrial sectors.