Bronze Casting for Durable Marine and Industrial Components

Bronze casting creates strong, corrosion‑resistant metal parts by pouring molten bronze into molds, producing components for marine hardware, valves, bearings, industrial machinery and architectural applications. This time‑tested process delivers reliable performance where strength and longevity are essential.

Bronze Alloy Composition

Bronze is primarily copper (88%) and tin (12%), with alloying elements added for specific properties:

- Tin bronze: High wear resistance for bearings and gears

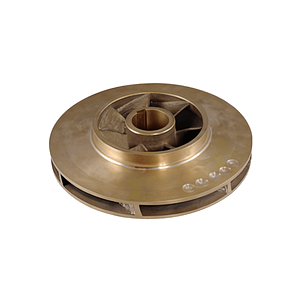

- Aluminum bronze: Exceptional strength for marine propellers and pump parts

- Silicon bronze: Good weldability for structural castings

- Leaded bronze: Enhanced machinability for precision components

Alloy choice matches mechanical, corrosion and service requirements.

Industrial and Marine Applications

Bronze castings excel in demanding environments:

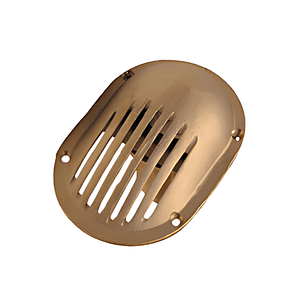

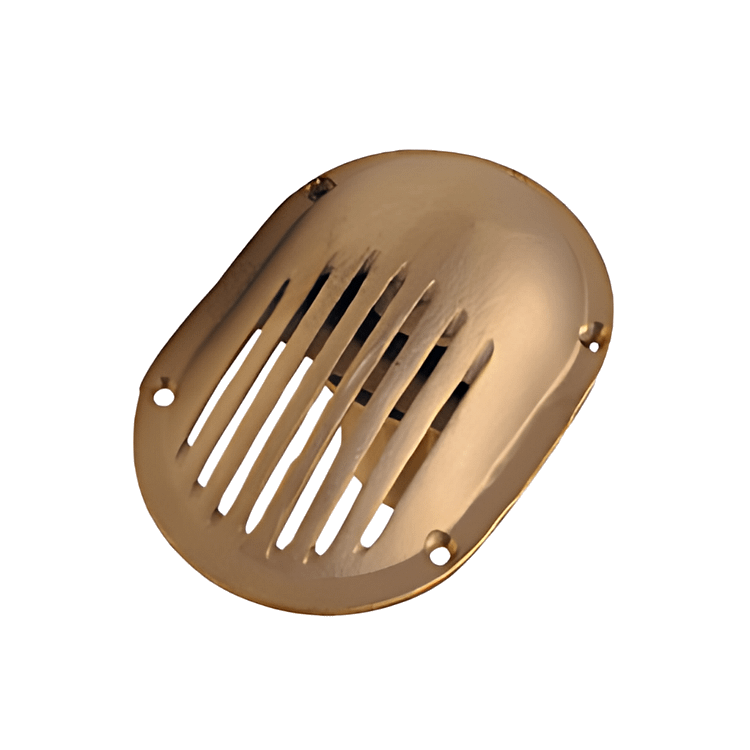

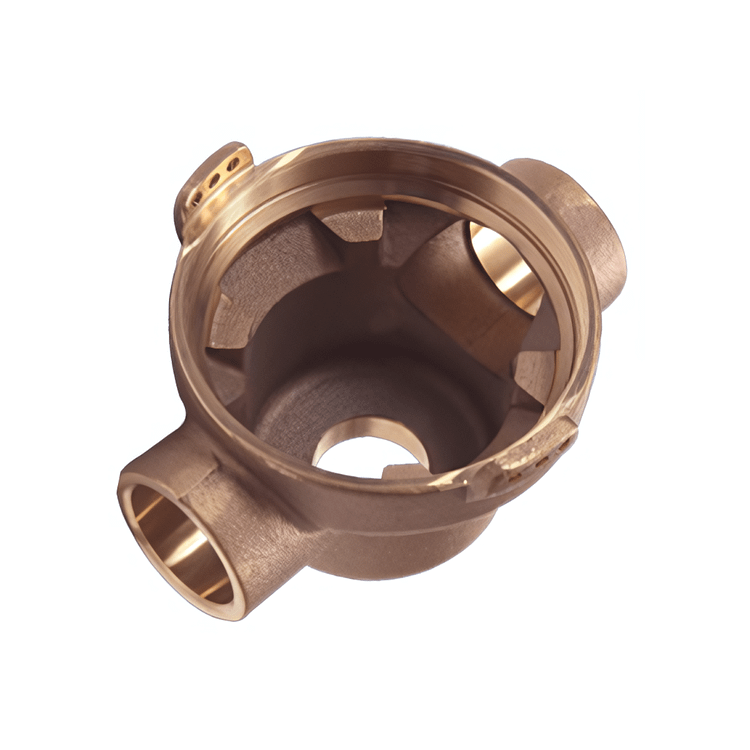

- Marine: Propellers, rudders, pump impellers, valve bodies

- Industrial: Bearings, bushings, gears, wear plates

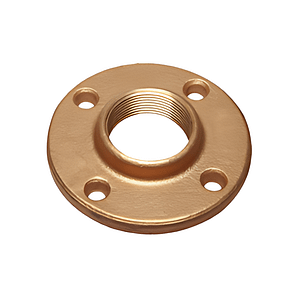

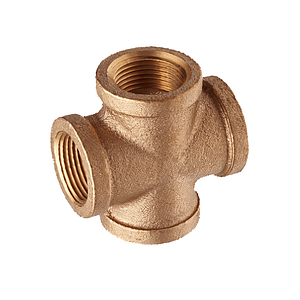

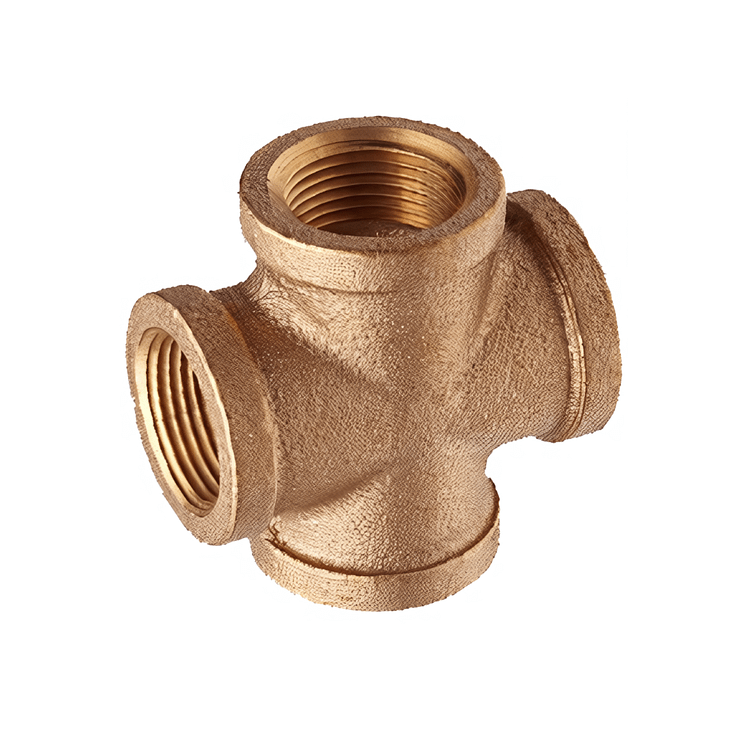

- Valves and fittings: Bodies, bonnets, seats for water, oil, gas

- Architecture: Door hardware, railings, sculptures

Cast bronze withstands seawater, industrial fluids and outdoor exposure.

Complex Geometries and Fine Details

Casting captures intricate shapes and internal features:

- Thin walls, cores and multi‑port designs

- Artistic textures and surface patterns

- Near‑net shapes minimizing machining

- Undercuts and complex passages

Sand casting and lost wax methods both support high design freedom.

Exceptional Durability and Corrosion Resistance

Bronze castings offer superior performance:

- Excellent seawater and chemical resistance

- High fatigue strength under dynamic loads

- Natural wear resistance in sliding applications

- Long service life with minimal maintenance

This longevity reduces replacement costs in marine and industrial service.

Custom Bronze Casting Solutions

Bronze casting supports bespoke production:

- Pattern design from drawings or 3D models

- Alloy selection for specific performance needs

- Controlled processes for consistent quality

- Secondary machining and finishing to spec

- Suitable for prototypes through production volumes.

Sustainable and Recyclable Material

Bronze retains properties after recycling:

- High scrap recovery from manufacturing

- Reduced virgin material requirements

- Long component life minimizes waste

Environmentally responsible engineering material.

Conclusion

Bronze casting produces durable, corrosion‑resistant components for marine, industrial valve, bearing and architectural applications. Combining proven casting techniques with modern alloy engineering, bronze castings deliver long‑life performance where mechanical reliability and environmental resistance matter most.