The Ultimate Guide to Bronze Alloy Casting: India’s Industrial Backbone

From the massive shipyards of Visakhapatnam to the precision machine shops of Jamnagar, bronze alloy casting is the silent engine driving Indian infrastructure. Known for its incredible corrosion resistance and “non-sparking” properties, bronze remains the gold standard for heavy-duty industrial components.

But with so many grades—Gunmetal, Phosphor Bronze, and Aluminum Bronze—how do you choose the right casting process for your project?

1. Popular Bronze Alloys in the Indian Market

In India, the choice of alloy is often dictated by the specific environmental challenges, such as high humidity in coastal regions or extreme heat in industrial belts.

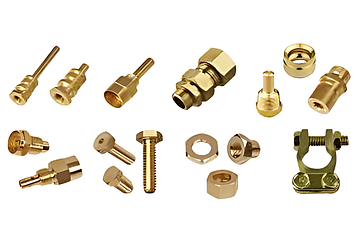

- Gunmetal (Leaded Tin Bronze): Extremely popular in India for plumbing and pump parts. It’s prized for being “pressure-tight” and easy to machine.

- Phosphor Bronze (PB1/PB2): The go-to for heavy-duty gears and worm wheels. It offers superior wear resistance, making it a staple in Indian textile and paper mills.

- Aluminum Bronze (AB1/AB2): Essential for the Indian Navy and Marine industry. It resists seawater corrosion better than almost any other non-ferrous alloy.

2. Choosing the Right Casting Process

Indian foundries typically specialize in three core methods. Your choice depends on your volume and required precision.

Sand Casting (Best for Large Parts)

Commonly used in hubs like Rajkot and Ahmedabad, sand casting is cost-effective for large components like pump casings or valve bodies.

- Pros: Low tooling cost; handles parts from 500g up to 500kg.

- Best for: Industrial valves and heavy machinery.

Investment Casting (Lost Wax Process)

For intricate designs that require “near-net-shape” accuracy, investment casting is the winner. This process reduces the need for expensive CNC machining later.

- Pros: Exceptional surface finish (Ra 3.2 to 6.3).

- Best for: Aerospace, defense, and high-end decorative hardware.

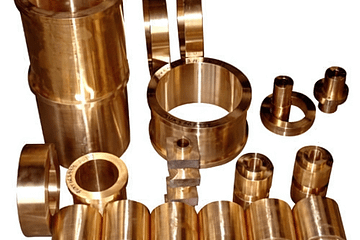

Centrifugal Casting

Used extensively for manufacturing bronze bushes and bearings. By spinning the mold at high speeds, impurities are forced to the center, leaving a dense, defect-free outer shell.

3. Understanding Bronze Casting Prices in India

Pricing in India is usually quoted on a per kilogram (₹/kg) basis, plus a “pattern charge” or “tooling cost.”

As of 2026, the price of bronze casting in India typically ranges from ₹750 to ₹1,200 per kg, depending on:

- LME Copper Prices: Since bronze is 80-90% copper, global market shifts hit Indian prices fast.

- Alloy Grade: Phosphor bronze and High-Nickel Aluminum bronze carry a premium over standard gunmetal.

- Complexity: Thin-walled or high-precision parts have higher rejection rates, increasing the cost.

4. Why Source Bronze Castings from India?

India has emerged as a global hub for non-ferrous castings for three reasons:

- Compliance: Top foundries now hold ISO 9001:2015 and AS9100 (Aerospace) certifications.

- Strategic Clusters: Regions like Jamnagar offer a complete ecosystem—from raw material ingots to advanced electroplating and NDT (Non-Destructive Testing).

- Customization: Indian manufacturers are highly flexible with small-to-medium batch sizes compared to large-scale Chinese factories.

Conclusion: Quality is Non-Negotiable

Whether you are sourcing for a chemical plant in Gujarat or a marine project in Kochi, the quality of your bronze alloy casting determines the lifespan of your machinery. Always ask for a Material Test Certificate (MTC) and ensure your supplier follows IS (Indian Standards) or ASTM guidelines.

Are you looking for a verified list of Bronze Casting foundries in Jamnagar or Pune for your next project? I can help you compile one!

0 Comments