Brass Turned Components by BOLTORQ Brassmet: Precision, Quality, and Reliability

Brass Turned Components – Introduction

In the world of manufacturing and engineering, precision components are crucial for the successful operation of machinery and equipment. Brass turned components are among the most sought-after parts due to their excellent mechanical properties, durability, and versatility. BOLTORQ Brassmet, a leading manufacturer of brass components, offers a wide array of high-quality brass turned components that cater to various industries. This blog explores the features, benefits, types, applications, and manufacturing excellence of BOLTORQ Brassmet’s brass turned components.

Why Brass Turned Components?

Brass turned components are preferred for several compelling reasons:

- Corrosion Resistance: Brass is inherently resistant to corrosion, making it ideal for components exposed to moisture and chemicals.

- Durability: Brass components offer excellent strength and longevity, ensuring reliable performance in demanding environments.

- Machinability: Brass is easily machined to precise dimensions, allowing for the production of complex and intricate parts.

- Thermal Conductivity: Brass has superior thermal conductivity, which is essential in applications requiring heat dissipation.

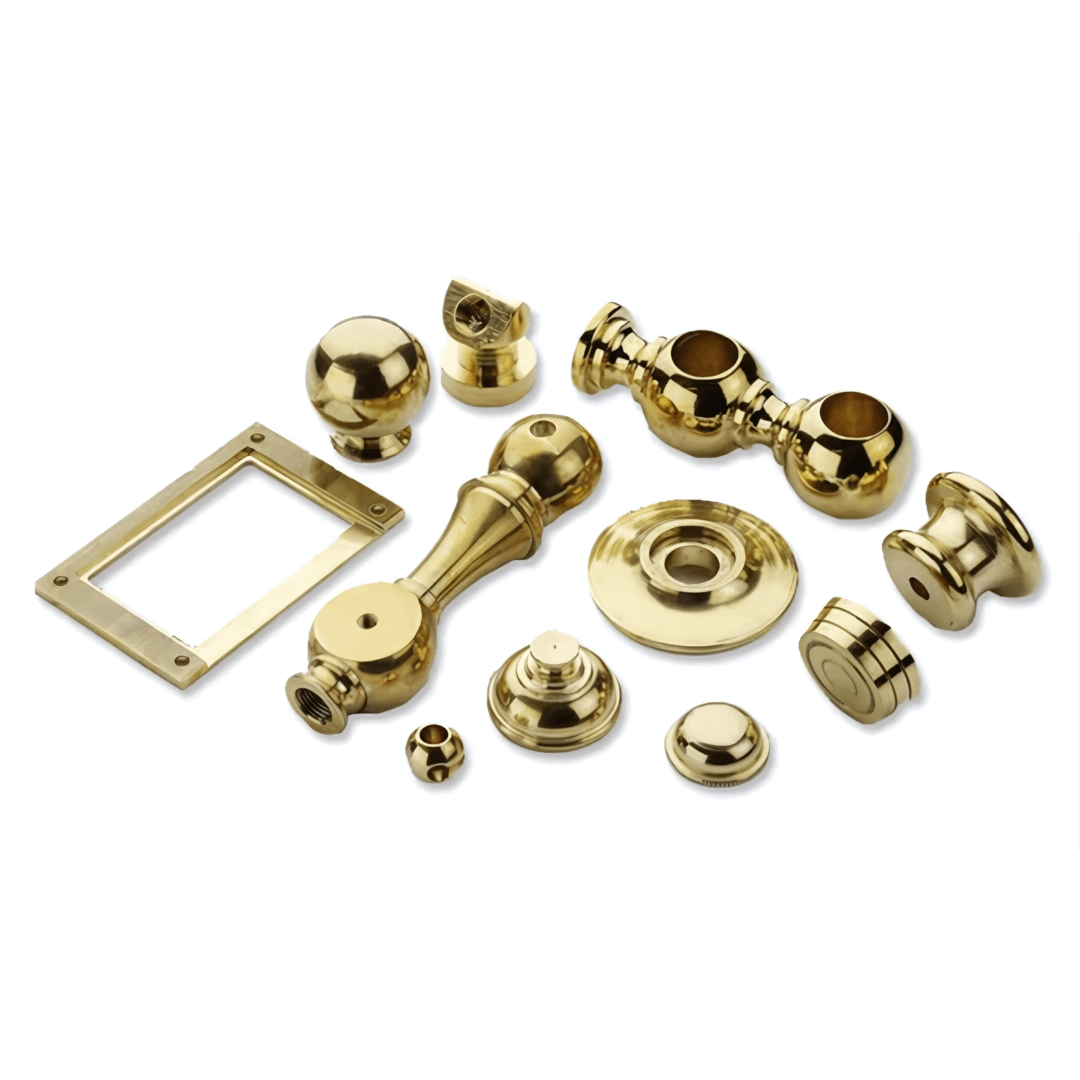

- Aesthetic Appeal: Brass components have a polished, attractive appearance, suitable for both functional and decorative purposes.

BOLTORQ Brassmet: A Leader in Brass Turned Components

BOLTORQ Brassmet is renowned for its commitment to quality and precision in manufacturing brass components. Here’s why BOLTORQ Brassmet stands out in the industry:

- High-Quality Materials: BOLTORQ Brassmet uses premium-grade brass to ensure the durability and reliability of their turned components.

- State-of-the-Art Manufacturing: Advanced machining techniques and equipment are employed to produce components with exacting precision.

- Comprehensive Range: BOLTORQ Brassmet offers a wide variety of brass turned components tailored to different industrial applications.

- Stringent Quality Control: Each component undergoes rigorous testing to meet or exceed industry standards for performance and safety.

- Exceptional Customer Support: BOLTORQ Brassmet provides expert assistance to help clients select the right components for their specific needs.

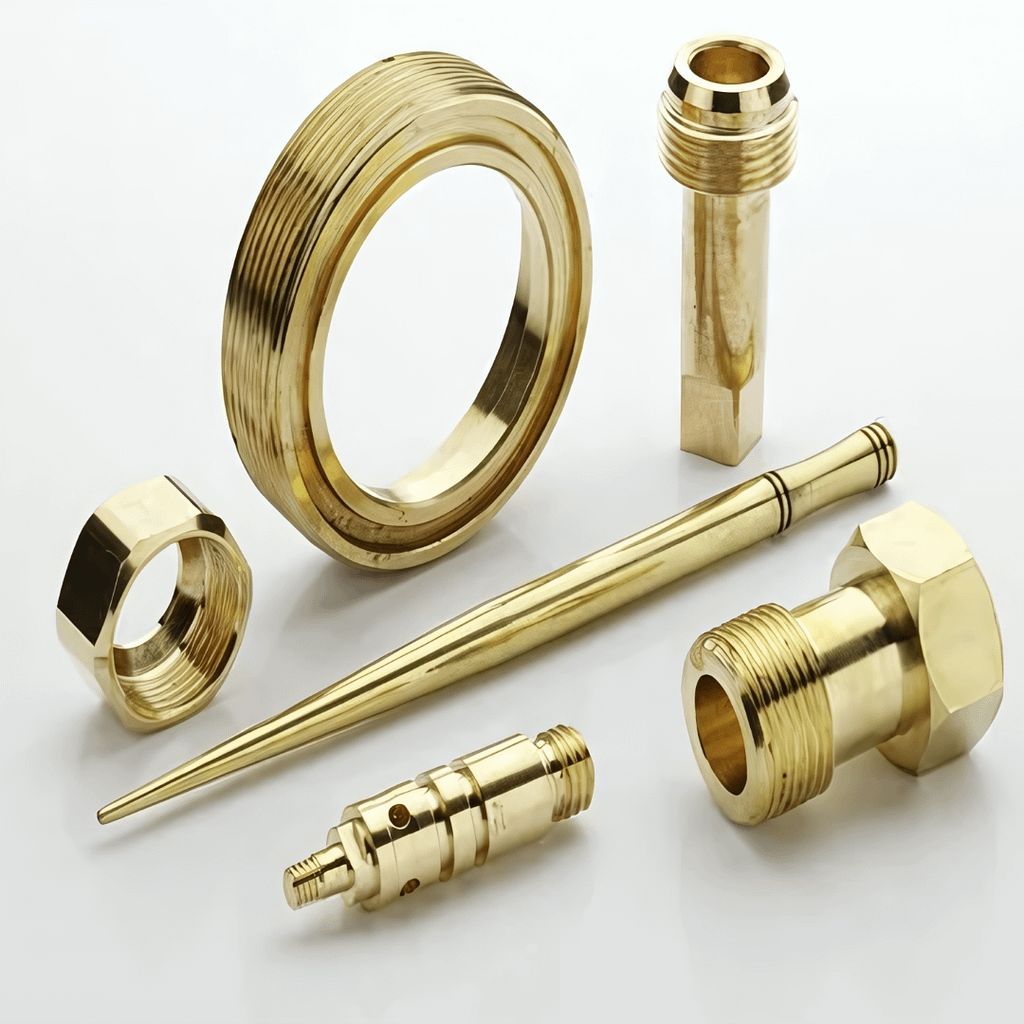

Types of Brass Turned Components by BOLTORQ Brassmet

1. Brass Shafts

Brass shafts are essential in various mechanical systems where rotational motion and torque transfer are required. They are known for their strength and durability.

Applications:

- Motors and generators

- Gear assemblies

- Precision instruments

Features:

- High tensile strength

- Excellent corrosion resistance

- Precision machining for accurate dimensions

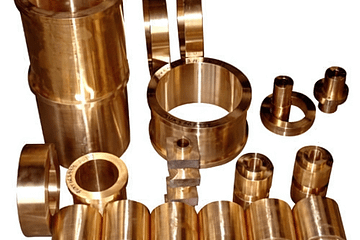

2. Brass Bushings

Brass bushings are used to reduce friction between moving parts. They are crucial in ensuring smooth operation and longevity of machinery.

Applications:

- Automotive engines

- Industrial machinery

- Marine equipment

Features:

- Low friction

- High wear resistance

- Long service life

3. Brass Spacers

Brass spacers are used to maintain a specified distance between components. They are critical in assembly processes where precise alignment is necessary.

Applications:

- Electronics

- Mechanical assemblies

- Aerospace

Features:

- Precision dimensions

- Durable and corrosion-resistant

- Easy to install

4. Brass Fittings

Brass fittings are used to connect pipes, tubes, and hoses in fluid systems. They ensure leak-proof connections and reliable fluid transfer.

Applications:

- Plumbing systems

- Hydraulic systems

- Gas lines

Features:

- Leak-proof connections

- High pressure resistance

- Durable construction

5. Brass Connectors

Brass connectors are used in electrical and electronic applications to ensure secure and reliable connections. They provide excellent conductivity and durability.

Applications:

- Electrical wiring

- Circuit boards

- Automotive electrical systems

Features:

- High electrical conductivity

- Corrosion resistance

- Secure connections

6. Brass Nuts and Bolts

Brass nuts and bolts are essential fastening components used in various applications. They provide strong and durable connections that can withstand significant stress.

Applications:

- Construction

- Machinery

- Marine applications

Features:

- High strength

- Corrosion-resistant

- Precision threads

Key Features and Benefits of BOLTORQ Brassmet’s Brass Turned Components

1. Superior Durability

BOLTORQ Brassmet’s brass turned components are designed to withstand harsh conditions and maintain their performance over time. Their robust construction ensures longevity and reliability.

2. Excellent Corrosion Resistance

Brass’s natural resistance to corrosion makes these components ideal for use in environments where exposure to moisture, chemicals, or corrosive substances is common.

3. High Precision

Advanced machining processes ensure that BOLTORQ Brassmet’s brass turned components meet exacting specifications. This precision is critical for the reliable operation of complex systems.

4. Versatile Applications

BOLTORQ Brassmet’s extensive range of brass turned components caters to a wide variety of applications across different industries, ensuring that clients can find the right part for their needs.

5. Easy Installation

Designed for ease of use, BOLTORQ Brassmet’s brass turned components are straightforward to install, reducing downtime and labor costs during assembly and maintenance.

The Manufacturing Excellence of BOLTORQ Brassmet

Material Selection

BOLTORQ Brassmet begins with high-quality brass, ensuring that their components possess the necessary mechanical and physical properties. The alloy composition is carefully controlled to achieve the desired balance of strength, corrosion resistance, and machinability.

Precision Machining

Utilizing state-of-the-art CNC machines and other advanced machining technologies, BOLTORQ Brassmet manufactures brass turned components with precise dimensions and tolerances. This ensures a perfect fit and reliable performance in their intended applications.

Surface Finishing

Surface finishing techniques such as polishing, plating, and coating are employed to enhance the appearance and corrosion resistance of the components. This not only improves their aesthetic appeal but also extends their service life.

Quality Control

Every brass turned component undergoes stringent quality control measures, including dimensional inspections, performance evaluations, and durability testing, to ensure they meet the highest industry standards.

Custom Solutions

BOLTORQ Brassmet is committed to innovation and offers custom solutions tailored to specific client requirements. Whether it’s a unique part design or a special alloy composition, BOLTORQ Brassmet can provide components that meet the most demanding applications.

Applications of Brass Turned Components

Automotive

In the automotive industry, brass turned components such as shafts, bushings, and connectors are used to ensure the reliable operation of engines, transmissions, and electrical systems. Their durability and corrosion resistance are crucial in this demanding environment.

Electronics

Brass turned components in electronics include connectors, spacers, and fittings that provide secure and reliable connections. Their excellent conductivity and precision are essential for the performance and longevity of electronic devices.

Industrial Machinery

Brass turned components are used in industrial machinery to reduce friction, provide secure connections, and maintain precise alignment of parts. This includes bushings, shafts, and fittings that enhance the efficiency and durability of the machinery.

Plumbing and Fluid Systems

In plumbing and fluid systems, brass fittings and connectors are essential for ensuring leak-proof connections and reliable fluid transfer. Their corrosion resistance and durability make them ideal for use in water, gas, and hydraulic systems.

Aerospace

The aerospace industry relies on brass turned components for their precision, strength, and reliability. These components, including spacers and bushings, are used in critical applications where performance and safety are paramount.

Environmental and Safety Considerations

Sustainability

BOLTORQ Brassmet is dedicated to sustainable manufacturing practices. Brass is a recyclable material, and the company ensures that waste is minimized during production. Their products are designed for long-term use, reducing the need for frequent replacements and contributing to environmental conservation.

Safety Standards

All brass turned components by BOLTORQ Brassmet comply with international safety standards, ensuring they provide reliable protection and performance in their intended applications. Their components are tested for durability and safety, making them a trustworthy choice for manufacturers.

Conclusion

Brass turned components by BOLTORQ Brassmet represent the pinnacle of quality, durability, and performance in the manufacturing industry. With a comprehensive range of products designed to meet various applications, BOLTORQ Brassmet has become a trusted name in the field. Their commitment to precision engineering, quality assurance, and customer satisfaction ensures that their brass turned components are not only reliable but also built to last. Whether you’re working on an automotive project, electronic device, or industrial machinery, BOLTORQ Brassmet has the right brass components to meet your needs.

Explore the Range of BOLTORQ Brassmet Brass Turned Components

To learn more about BOLTORQ Brassmet and their extensive range of brass turned components, visit their website or contact their customer service team. Experience the quality and reliability that only BOLTORQ Brassmet can provide.

FAQs

1. What are the main benefits of using brass turned components?

Brass turned components offer excellent durability, corrosion resistance, and high thermal and electrical conductivity. They provide reliable and long-lasting performance in various applications.

2. Can brass turned components be used in high-temperature environments?

Yes, brass has excellent thermal conductivity and can withstand high temperatures, making it suitable for use in applications requiring heat dissipation.

3. How do I choose the right brass turned component for my application?

Consider factors such as the type of material, environmental conditions, and specific requirements of your application. Consulting with BOLTORQ Brassmet’s customer service can also help you make the right choice.

4. Are BOLTORQ Brassmet components environmentally friendly?

Yes, brass is a recyclable material, and BOLTORQ Brassmet employs sustainable manufacturing practices to minimize waste and environmental impact.

5. Do brass turned components require special

maintenance?

Brass turned components are low-maintenance but should be regularly inspected for any signs of wear or damage. Cleaning them periodically will help maintain their appearance and performance.

By choosing BOLTORQ Brassmet, you are investing in components that combine quality, durability, and exceptional performance, ensuring the success of your projects for years to come.

See more about out our products:

Brass Fitting Parts by BOLTORQ Brassmet: A Comprehensive Guide

Brass Cable Glands by BOLTORQ Brassmet: A Comprehensive Guide

Brass Auto Parts by BOLTORQ Brassmet: Driving Excellence in Automotive Components

Brass Inserts by BOLTORQ Brassmet: The Ultimate Guide

Brass Turned Components by BOLTORQ Brassmet: Precision, Quality, and Reliability

0 Comments