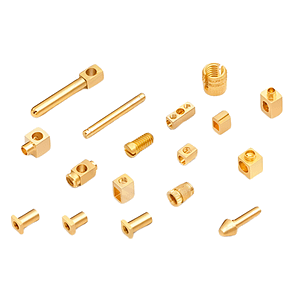

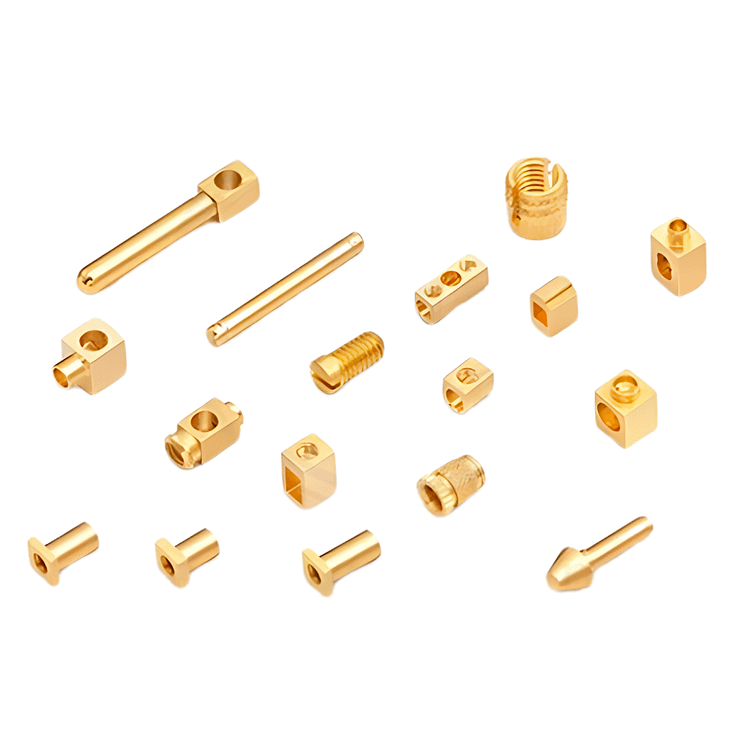

Brass Precision Components for High‑Accuracy Industrial Applications

Brass precision components are key elements in automotive, aerospace, electronics, medical and industrial equipment, where exact dimensions and reliable performance are essential. Produced using advanced CNC machining and precision turning, these components deliver the accuracy, durability and consistency required in modern high‑performance systems.

Precision and Accuracy with Advanced CNC Machining

The defining feature of brass precision components is their ability to meet tight tolerances and complex geometries. Using technologies such as CNC milling, CNC turning and multi‑axis machining, these parts can be produced with:

- Very fine dimensional accuracy and repeatability

- Clean surface finishes and precise threads or features

- Complex shapes tailored to demanding assemblies

This level of precision ensures that parts fit correctly, reduce assembly issues and support stable, long‑term operation in critical applications.

Material Advantages of Brass for Precision Parts

Brass, a copper‑zinc alloy, is widely chosen for precision components because it combines mechanical performance with excellent machinability and stability. Key advantages include:

- Good strength and wear resistance for moving or load‑bearing parts

- Outstanding machinability, enabling efficient production of intricate designs

- Corrosion resistance in many environments, including moisture and common industrial media

- Reliable thermal and electrical conductivity for electronic and electromechanical components

These properties make brass an ideal material for small, complex parts that must perform accurately over time.

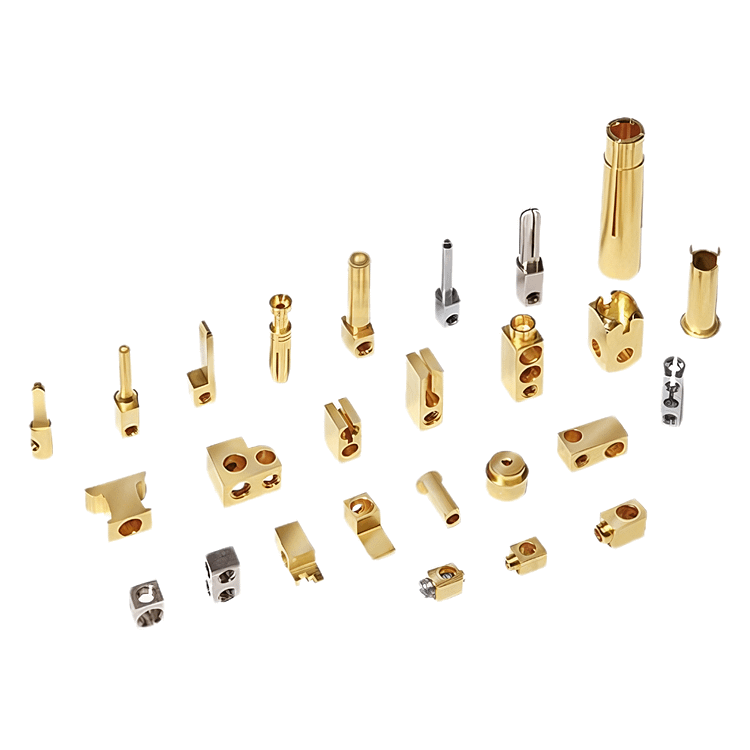

Versatile Use Across Global Industries

- Brass precision components are used in many sectors where safety, accuracy and reliability are non‑negotiable. Typical applications include:

- Automotive: Fuel and fluid system parts, sensor housings, braking and control components

- Aerospace: Precision fittings, connectors and small mechanisms that must perform under extreme conditions

- Electronics and electrical: Connectors, terminals, contact parts and shielding components requiring tight tolerances and stable conductivity

- Medical devices: Precision parts for diagnostic equipment, monitoring systems and non‑implantable medical instruments

- Industrial machinery: Custom fittings, valve components, instrumentation parts and control elements

- This breadth of usage underscores brass’s role as a core material in high‑precision engineering.

Cost‑Effective High‑Precision Manufacturing

Brass precision components offer an attractive balance of performance and cost. Thanks to brass’s machinability and predictable cutting behavior:

- Cycle times can be optimized for both small and large production runs

- Tool wear is manageable, supporting consistent quality and better economics

- Scrap can be efficiently recycled back into the production stream

Combined with long component life in service, these factors make brass precision parts a cost‑effective option for OEMs and contract manufacturers.

Customization and Design Flexibility

Modern CNC and precision machining allow brass components to be tailored precisely to customer requirements. Customization options can include:

- Dimensions and tolerances based on drawings or 3D models

- Specific profiles, threads, slots, ports and internal features

- Integrated multi‑function designs that reduce part count in assemblies

This flexibility supports product differentiation and innovation, enabling engineers to design components that match exact functional and packaging constraints.

Sustainability and Recycling Benefits

Brass is fully recyclable, which helps manufacturers and end users reduce environmental impact without sacrificing performance. Using brass precision components supports:

- Lower demand for virgin raw materials

- Efficient recovery and reuse of machining scrap

- Alignment with sustainability and ESG goals in supply chains

- This recyclability, combined with long service life, makes brass a responsible choice for precision parts in global markets.

Conclusion

Brass precision components provide the accuracy, stability and durability that modern technologies demand, from automotive and aerospace systems to electronics, industrial machinery and medical devices. With excellent machinability, corrosion resistance, electrical and thermal performance, and strong support for customization, they offer a robust and cost‑effective solution for high‑precision applications worldwide. As expectations for reliability and dimensional accuracy continue to rise, brass precision components remain a trusted foundation for advanced engineering and manufacturing.