Brass Inserts by BOLTORQ Brassmet: The Ultimate Guide

What Are Brass Inserts? Professional Solutions for Industrial Fastening

Brass inserts are precision-engineered threaded fasteners designed to provide durable, reusable threads in materials including plastics, wood, and soft metals. These metal inserts serve as critical components across electronics manufacturing, automotive assembly, industrial applications, and precision engineering sectors worldwide.

Industrial manufacturers, design engineers, and procurement specialists choose brass threaded inserts for their superior mechanical properties, exceptional corrosion resistance, and long-term reliability in demanding applications.

BOLTORQ Brassmet: Industry-Leading Brass Insert Manufacturer

BOLTORQ Brassmet has established itself as a premier manufacturer of precision brass inserts, serving global markets across North America, Europe, Asia-Pacific, and emerging industrial regions.

Manufacturing Excellence Standards

Premium Brass Alloy Composition

BOLTORQ Brassmet utilizes certified brass alloys meeting international standards including ISO 9001, RoHS compliance, and REACH regulations for consistent material properties.

CNC Precision Manufacturing

Advanced computer-controlled machining centers ensure dimensional accuracy within ±0.01mm tolerances, critical for automotive-grade and aerospace applications.

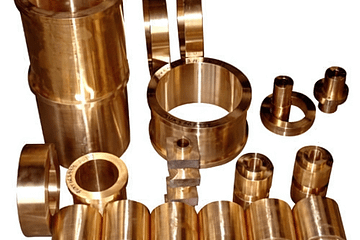

Comprehensive Product Portfolio

From M2 micro inserts to M20 heavy-duty solutions, BOLTORQ Brassmet manufactures threaded inserts, knurled inserts, heat-set inserts, ultrasonic inserts, and self-tapping brass inserts.

Quality Assurance Testing

Every production batch undergoes pull-out force testing, torque resistance evaluation, salt spray testing, and dimensional inspection per ASTM and DIN standards.

Technical Engineering Support

Dedicated application engineers provide insert selection guidance, installation recommendations, and custom brass insert design services for specialized requirements.

Types of Brass Inserts by BOLTORQ Brassmet

1. Threaded Brass Inserts for Plastic and Metal Applications

Precision-threaded brass inserts create permanent, high-strength internal threads in host materials including thermoplastics, thermosets, wood composites, and aluminum alloys.

Industrial Applications:

- Electronic enclosure assembly

- Plastic housing manufacturing

- Furniture hardware installation

- Medical device assembly

- Telecommunications equipment

Key Technical Features:

- Thread sizes: M2 to M20 (metric), #2-56 to 1/2″-13 (imperial)

- Pull-out resistance: 200-2000N depending on size

- Installation methods: Press-in, heat-set, ultrasonic

- Material compatibility: ABS, PC, Nylon, PVC, wood, aluminum

2. Knurled Brass Inserts for Enhanced Grip Performance

Diamond-knurled or straight-knurled brass inserts feature precision-cut external patterns that prevent rotation and pull-out in thermoplastic assemblies.

Common Applications:

- Injection molded components

- Glass-filled nylon assemblies

- Composite material fastening

- Light metal fabrication

- 3D printed part reinforcement

Performance Specifications:

- Knurl patterns: Diamond, straight, helical

- Installation torque: 15-50% lower than smooth inserts

- Retention force: 30% higher than non-knurled alternatives

- Temperature resistance: -40°C to +200°C

3. Heat-Set Brass Inserts for Thermoplastic Materials

Heat-set inserts utilize thermal installation methods where controlled heating melts surrounding plastic, allowing secure embedment upon cooling for maximum holding strength.

Optimal Applications:

- 3D printed prototypes and production parts

- Injection molded plastic assemblies

- Consumer electronics housings

- Automotive interior components

- Drone and robotics assembly

Installation Advantages:

- Installation time: 3-5 seconds per insert

- Equipment required: Heat-set tool, soldering iron, ultrasonic welder

- Bond strength: Permanent mechanical interlock

- Recommended plastics: ABS, Nylon, PC, PEEK, PET

4. Ultrasonic Brass Inserts for Precision Assembly

Ultrasonic installation brass inserts employ high-frequency vibration (20-40 kHz) to generate localized heating through friction, enabling precise placement without external heat sources.

Precision Applications:

- Medical device manufacturing

- Automotive sensor assemblies

- Consumer electronics (smartphones, tablets)

- Aerospace components

- Clean room assembly operations

Technical Specifications:

- Installation frequency: 20kHz, 30kHz, 40kHz

- Installation time: 0.5-2 seconds

- Positional accuracy: ±0.05mm

- Contamination: Zero-emission process

- Automation compatibility: Fully robotic-ready

5. Self-Tapping Brass Inserts for Quick Installation

Self-tapping brass inserts feature cutting threads that form mating threads during installation, eliminating pre-tapping operations in wood, soft plastics, and aluminum.

Application Sectors:

- Woodworking and cabinetry

- Plastic product assembly

- Soft metal fabrication

- Repair and retrofit applications

- Field installation scenarios

Installation Benefits:

- No pre-drilling or tapping required

- Installation speed: 50% faster than standard inserts

- Driving methods: Screwdriver, hex key, power tools

- Reusability: Multiple installation cycles possible

Key Features and Benefits

1. Superior Durability

BOLTORQ Brassmet’s brass inserts are built to last, providing long-term reliability even in demanding applications. Their robust construction ensures they can withstand significant wear and tear.

2. Excellent Corrosion Resistance

Brass offers natural resistance to corrosion, making these inserts ideal for use in environments where exposure to moisture, chemicals, or corrosive substances is a concern.

3. High Precision

Precision engineering ensures that BOLTORQ Brassmet’s brass inserts fit perfectly into their intended applications, providing a secure and reliable connection.

4. Versatile Applications

BOLTORQ Brassmet’s wide range of brass inserts caters to various applications, from electronics and automotive to manufacturing and construction.

5. Easy Installation

Designed for ease of use, BOLTORQ Brassmet’s brass inserts are straightforward to install, reducing downtime and labor costs during assembly and maintenance.

Advanced Manufacturing Process: BOLTORQ Quality Standards

Raw Material Sourcing

BOLTORQ Brassmet sources certified brass alloys (CuZn37, CuZn39Pb3, CuZn40) from ISO-certified suppliers, with material traceability and composition verification for every production batch.

CNC Precision Machining

Multi-axis Swiss-type CNC lathes and machining centers produce brass inserts with:

- Dimensional tolerance: ±0.01mm

- Surface finish: Ra 0.8-1.6 μm

- Thread accuracy: ISO 965-1 Class 6H

- Production capacity: 5 million units monthly

Surface Treatment Options

Available Finishes:

- Natural brass (standard)

- Nickel plating (enhanced corrosion resistance)

- Tin plating (lead-free compliance)

- Passivation (chemical resistance)

- Custom finishes available

Quality Control Protocols

Inspection Procedures:

- Incoming material spectroscopy analysis

- In-process statistical process control (SPC)

- Final dimensional inspection (100% automated)

- Pull-out force testing (sample-based per ISO 2859)

- Thread gauge verification per ISO 1502

Custom Brass Insert Design Services

BOLTORQ Brassmet engineering team provides:

- Prototype development and testing

- Custom thread specifications

- Proprietary knurl patterns

- Special alloy compositions

- Unique geometric designs

Industrial Applications of Brass Inserts by Sector

Electronics Manufacturing

Applications:

Circuit board mounting, connector housings, smartphone assemblies, laptop enclosures, LED lighting fixtures, power supply units, control panels

Why Brass Inserts:

EMI shielding, electrical grounding, heat dissipation, corrosion resistance, precision assembly

Automotive Industry

Applications:

Dashboard assemblies, door panel mounting, engine covers, sensor housings, trim components, electrical connectors, seat mechanisms

Industry Standards:

IATF 16949 certified, vibration resistant per ISO 16750, temperature range -40°C to +150°C

Industrial Manufacturing

Applications:

Assembly line fixtures, robotic end-effectors, pneumatic components, hydraulic systems, control cabinets, safety equipment

Performance Requirements:

High cycle durability, chemical resistance, dimensional stability, automated installation compatibility

Construction and Building

Applications:

Curtain wall systems, window assemblies, door hardware, HVAC components, electrical panels, composite panel fastening

Environmental Considerations:

Weather resistance, UV stability, thermal expansion compatibility, long-term reliability

Consumer Products

Applications:

Furniture assembly, appliance manufacturing, sporting goods, toys and games, consumer electronics, home improvement products

Regulatory Compliance:

RoHS, REACH, CPSIA (Consumer Product Safety Improvement Act), lead-free requirements

Medical Devices

Applications:

Diagnostic equipment, surgical instruments, patient monitoring devices, rehabilitation equipment, laboratory instruments

Certifications:

ISO 13485 medical device quality management, biocompatibility testing, FDA compliance documentation

Brass Insert Selection Guide: Engineering Considerations

Material Compatibility Assessment

Thermoplastics:

Heat-set or ultrasonic inserts recommended for ABS, PC, Nylon, PBT, PET, PEEK

Thermosets:

Press-in or self-tapping inserts suitable for phenolic, epoxy, polyester composites

Wood Materials:

Self-tapping or knurled inserts for softwood, hardwood, MDF, particleboard, plywood

Metals:

Threaded inserts for aluminum, magnesium, zinc alloys (not recommended for steel)

Load Requirements Analysis

Static Loads:

Pull-out resistance 200N (M2) to 5000N (M12+)

Torque capacity 0.5 Nm (M2) to 25 Nm (M12+)

Dynamic Loads:

Vibration resistance per ISO 16750-3

Fatigue testing per ASTM E466

Environmental Factors:

Temperature cycling, humidity exposure, chemical contact, UV radiation

Installation Method Selection

Manual Installation:

Heat guns, soldering irons, hand tools for prototypes and low-volume production

Semi-Automated:

Pneumatic heat-set tools, bench-mount ultrasonic stations for medium production

Fully Automated:

Robotic ultrasonic systems, in-line heat-set equipment for high-volume manufacturing

Geographic Market Presence and Distribution

1. North America

BOLTORQ Brassmet serves automotive hubs (Detroit, Ontario), electronics manufacturing (Silicon Valley, Austin), and industrial centers across USA, Canada, and Mexico with localized inventory and technical support.

2. Europe

Distribution network covering Germany (automotive), UK (aerospace), France (industrial), Italy (manufacturing) with CE marking compliance and EU regulatory expertise.

3. Asia-Pacific

Manufacturing support across China (electronics), India (automotive), Japan (precision equipment), South Korea (consumer electronics), Southeast Asia (contract manufacturing).

4. Emerging Markets

Growing presence in Middle East (construction, oil & gas), Latin America (manufacturing), Africa (infrastructure development).

Conclusion

Brass inserts by BOLTORQ Brassmet represent the pinnacle of quality, durability, and performance. With a comprehensive range of products designed to meet various applications, BOLTORQ Brassmet has become a trusted name in the industry. Their commitment to precision engineering, quality assurance, and customer satisfaction ensures that their brass inserts are not only reliable but also built to last. Whether you’re working on an electronics project, automotive assembly, or manufacturing application, BOLTORQ Brassmet has the right brass inserts to meet your needs.

Explore the Range of BOLTORQ Brassmet Brass Inserts

To learn more about BOLTORQ Brassmet and their extensive range of brass inserts, visit their website or contact their customer service team. Experience the quality and reliability that only BOLTORQ Brassmet can provide.

FAQs

1. What are the primary advantages of brass inserts over steel alternatives?

Brass inserts offer superior corrosion resistance in humid and marine environments, excellent thermal and electrical conductivity for electronics applications, easier machining and installation, and non-magnetic properties for sensitive equipment. Steel inserts provide higher strength but may require additional corrosion protection coatings.

2. Can brass inserts withstand high-temperature industrial applications?

Yes, brass inserts maintain structural integrity and thread strength at continuous operating temperatures up to 200°C (392°F). For extreme temperature applications exceeding 250°C, BOLTORQ Brassmet offers specialized high-temperature brass alloys and can recommend alternative materials like stainless steel inserts.

3. How do I choose the right brass insert for my application?

Consider factors such as the type of material, environmental conditions, and specific requirements of your application. Consulting with BOLTORQ Brassmet’s customer service can also help you make the right choice.

4. Can brass inserts be used in outdoor and marine environments?

Absolutely. Brass alloys demonstrate excellent performance in outdoor installations and marine applications due to natural corrosion resistance. For severe marine environments, BOLTORQ Brassmet recommends nickel-plated brass inserts providing enhanced protection. Salt spray testing validates 1000+ hour corrosion resistance per ASTM B117 standards.

5. Do brass inserts require special maintenance?

Brass inserts are low-maintenance but should be regularly inspected for any signs of wear or damage. Cleaning them periodically will help maintain their appearance and performance.

By choosing BOLTORQ Brassmet, you are investing in inserts that combine quality, durability, and exceptional performance, ensuring the success of your projects for years to come.

See more about out our products:

Brass Fitting Parts by BOLTORQ Brassmet: A Comprehensive Guide

Brass Cable Glands by BOLTORQ Brassmet: A Comprehensive Guide

Brass Auto Parts by BOLTORQ Brassmet: Driving Excellence in Automotive Components

Brass Inserts by BOLTORQ Brassmet: The Ultimate Guide

Brass Turned Components by BOLTORQ Brassmet: Precision, Quality, and Reliability

0 Comments