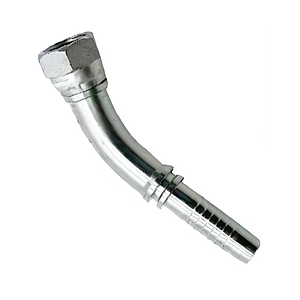

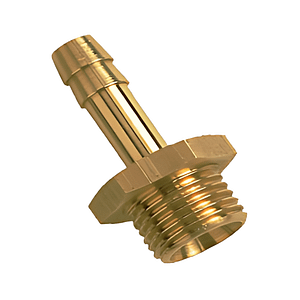

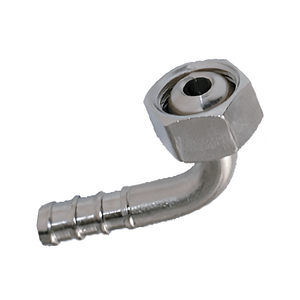

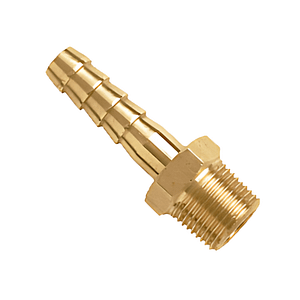

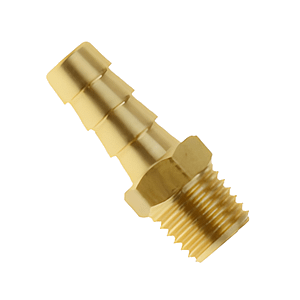

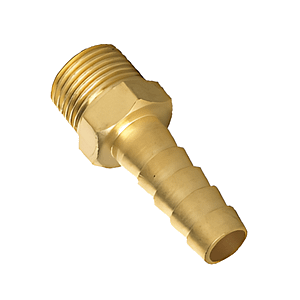

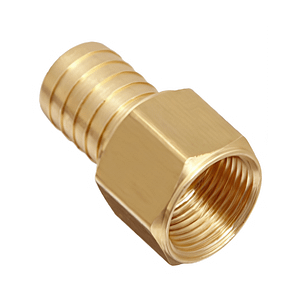

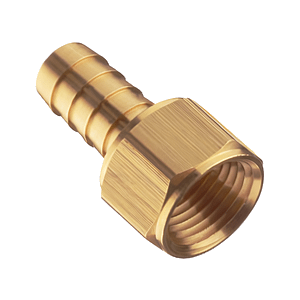

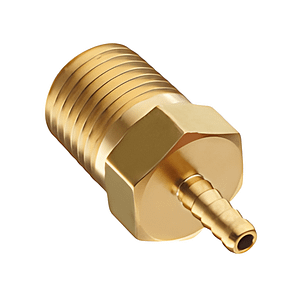

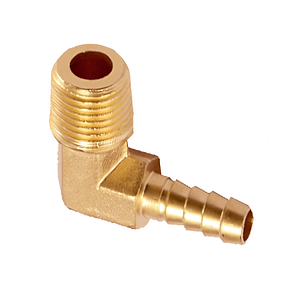

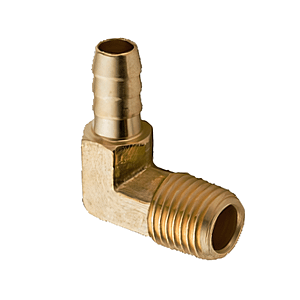

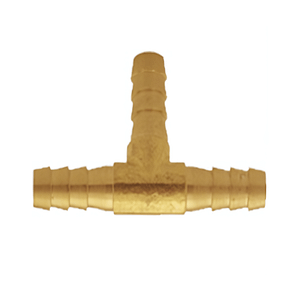

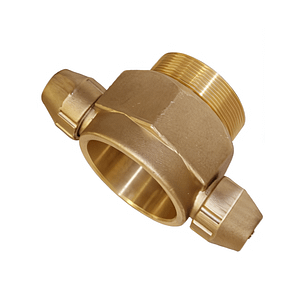

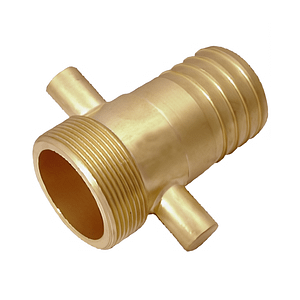

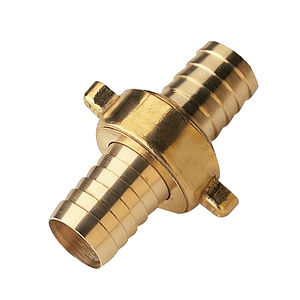

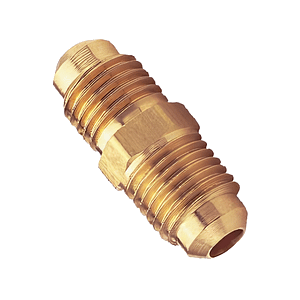

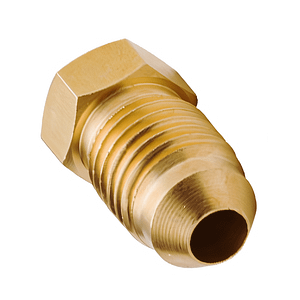

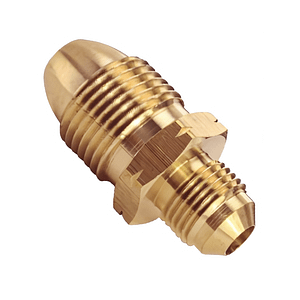

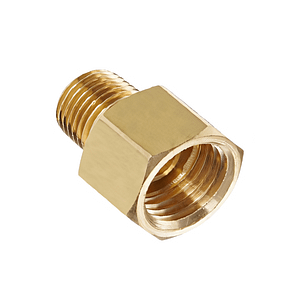

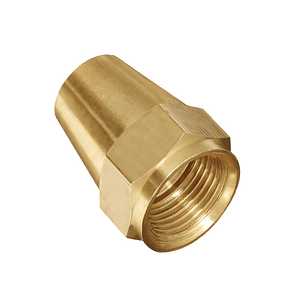

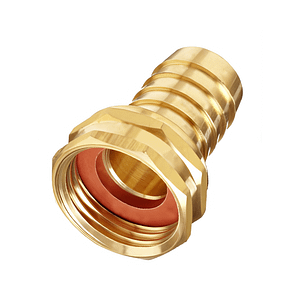

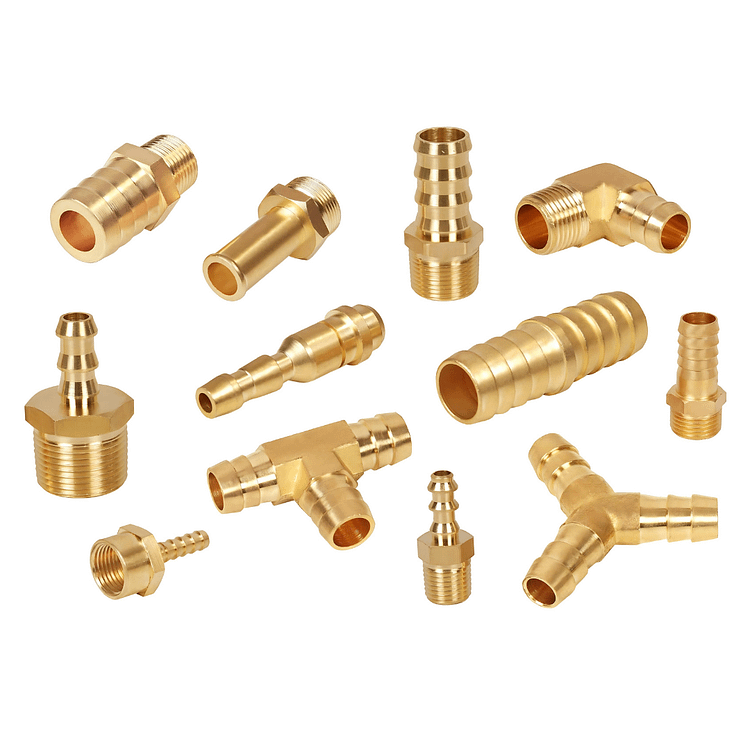

Brass Hose Fittings

Brass hose fittings are essential components used to connect hoses to various equipment, fixtures, and piping systems for fluid transfer applications. These fittings play a crucial role in ensuring leak-free connections, controlling fluid flow, and adapting hoses to different configurations and requirements. Crafted from high-quality brass alloys, these fittings offer durability, corrosion resistance, and versatility, making them a preferred choice for industries such as plumbing, automotive, irrigation, and pneumatic systems.

Durability and Corrosion Resistance

One of the primary advantages of brass hose fittings is their exceptional durability and resistance to corrosion. Brass, an alloy of copper and zinc, offers excellent mechanical properties, including high tensile strength and toughness, making it ideal for use in demanding fluid transfer applications. Additionally, brass is inherently resistant to rust, oxidation, and chemical corrosion, ensuring long-lasting performance even in harsh environments. This durability and corrosion resistance make brass hose fittings suitable for both indoor and outdoor applications, including plumbing systems, irrigation systems, and marine environments.

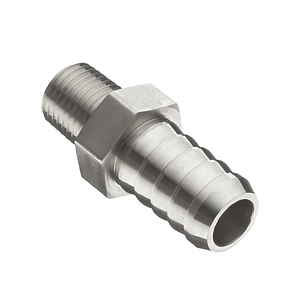

Versatility in Applications

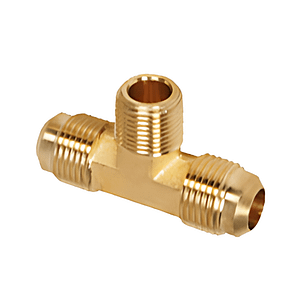

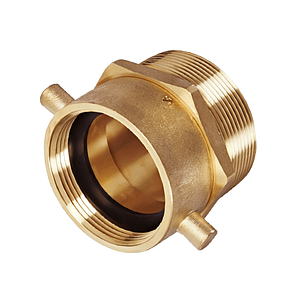

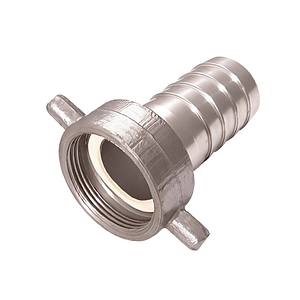

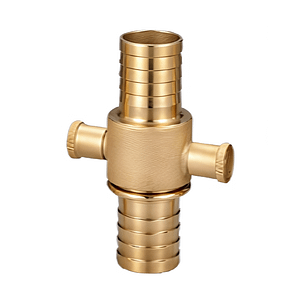

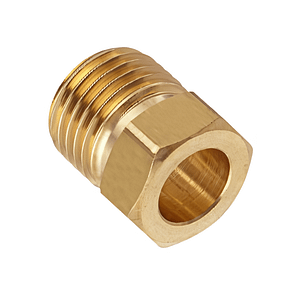

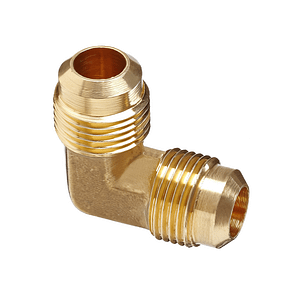

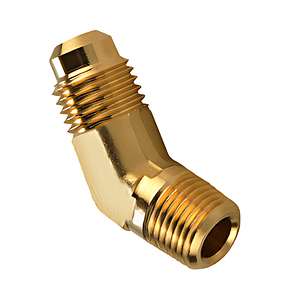

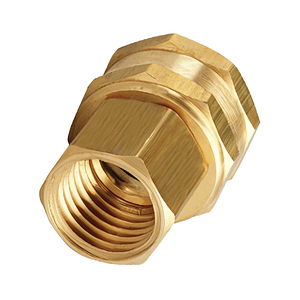

Brass hose fittings are highly versatile and find application across various industries and fluid transfer systems. Whether used in hydraulic systems, pneumatic equipment, HVAC (heating, ventilation, and air conditioning) systems, or garden irrigation, brass fittings provide reliable connections and efficient fluid flow control. They are available in a wide range of configurations, including straight, elbow, tee, and cross fittings, as well as adapters, couplings, and reducers, to accommodate different hose sizes, thread types, and connection methods.

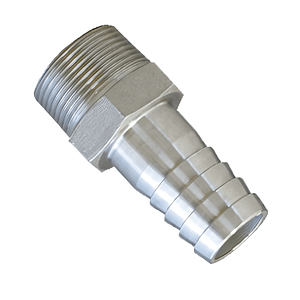

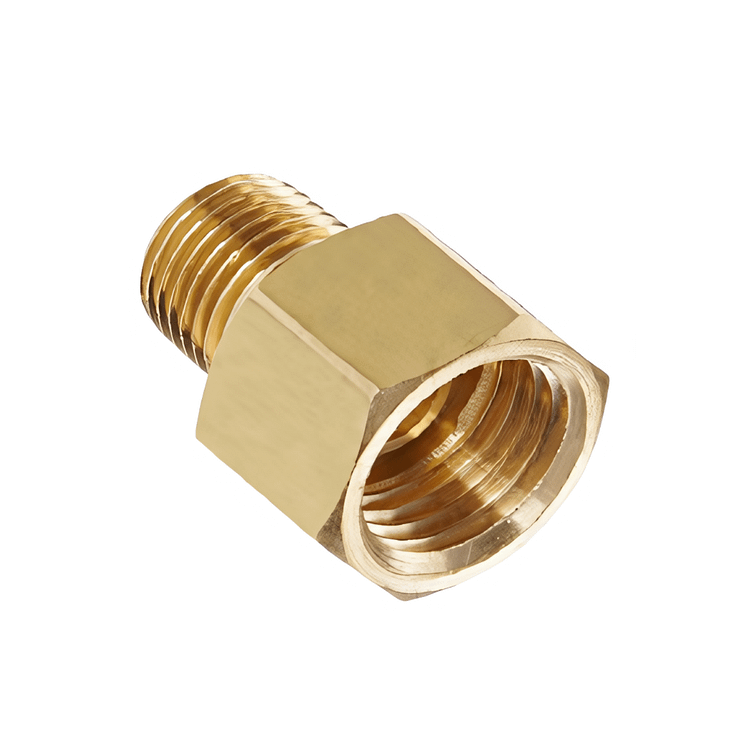

Ease of Installation and Maintenance

Installing brass hose fittings is a straightforward process that requires minimal tools and expertise. Most fittings feature threaded connections or compression fittings that can be easily tightened or secured using standard tools. Additionally, brass fittings are compatible with various types of hoses, including rubber, PVC (polyvinyl chloride), and thermoplastic hoses, allowing for seamless integration into existing systems. Routine maintenance of brass hose fittings typically involves inspecting for leaks, tightening connections, and replacing worn or damaged fittings as needed, ensuring optimal performance and reliability.

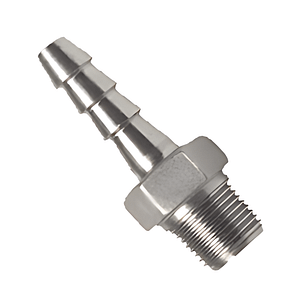

Temperature and Pressure Resistance

Brass hose fittings offer excellent temperature and pressure resistance, making them suitable for use in a wide range of operating conditions. Whether exposed to high temperatures in industrial applications or subjected to high pressures in hydraulic systems, brass fittings maintain their integrity and performance without deformation or failure. This temperature and pressure resistance ensure safe and reliable fluid transfer operations, minimizing the risk of leaks, spills, or accidents.

Environmental Sustainability

Brass is a sustainable material with excellent recyclability, making brass hose fittings an environmentally friendly choice for fluid transfer systems. Recycling brass reduces the need for virgin material extraction and minimizes waste, contributing to resource conservation and environmental protection. Additionally, brass fittings are durable and long-lasting, reducing the need for frequent replacements and minimizing environmental impact over time.

Conclusion

Brass hose fittings are indispensable components in fluid transfer systems, providing reliable connections, efficient fluid flow control, and durability in various applications. With their exceptional corrosion resistance, versatility, and ease of installation, brass fittings offer reliable solutions for industries ranging from plumbing and automotive to irrigation and pneumatic systems. As the demand for efficient and sustainable fluid transfer solutions continues to grow, brass hose fittings remain a preferred choice for engineers, contractors, and homeowners seeking high-quality and reliable fluid handling solutions.