Brass Fitting Parts

When it comes to plumbing, gas systems, and various industrial applications, brass fittings are often the go-to choice. Their durability, versatility, and corrosion resistance make them an essential component in numerous systems. In this article, we will explore what brass fittings are, their types, benefits, applications, and how to choose the right brass fitting for your needs.

Benefits of Brass Fittings

Brass fittings are highly valued in plumbing, gas systems, and various industrial applications due to their numerous benefits. One of the primary advantages is their exceptional resistance to corrosion. Brass is impervious to damage from water, chemicals, and environmental elements, making it an excellent choice for both indoor and outdoor applications. This resistance ensures longevity and reliability, even in harsh environments.

Durability is another significant benefit of brass fittings. They are robust and can withstand high pressure and extreme temperature variations without cracking or deforming. This makes them suitable for a wide range of demanding applications, ensuring long-lasting performance. Additionally, brass’s malleability allows it to be easily shaped and manufactured into complex fittings with precise specifications. This property is particularly useful in creating custom designs to meet specific needs.

Furthermore, brass has excellent thermal conductivity, which is advantageous in applications involving heat exchange, such as HVAC systems. This property enhances the efficiency of heating and cooling processes. Aesthetically, brass offers a gold-like appearance, making it a popular choice for visible installations in home decor and fixtures, where visual appeal is important alongside functionality.

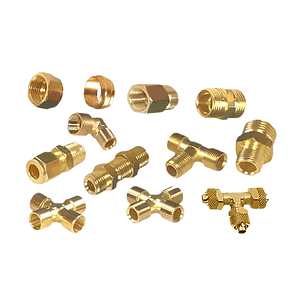

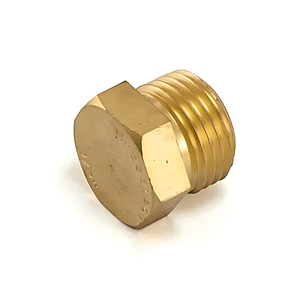

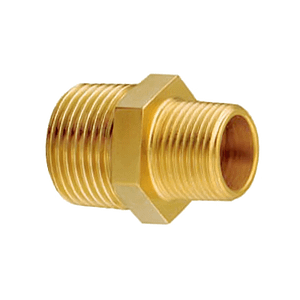

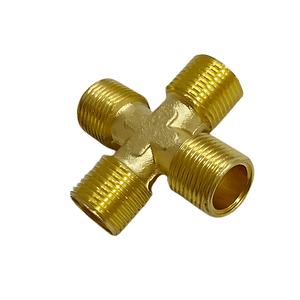

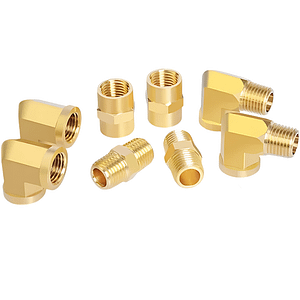

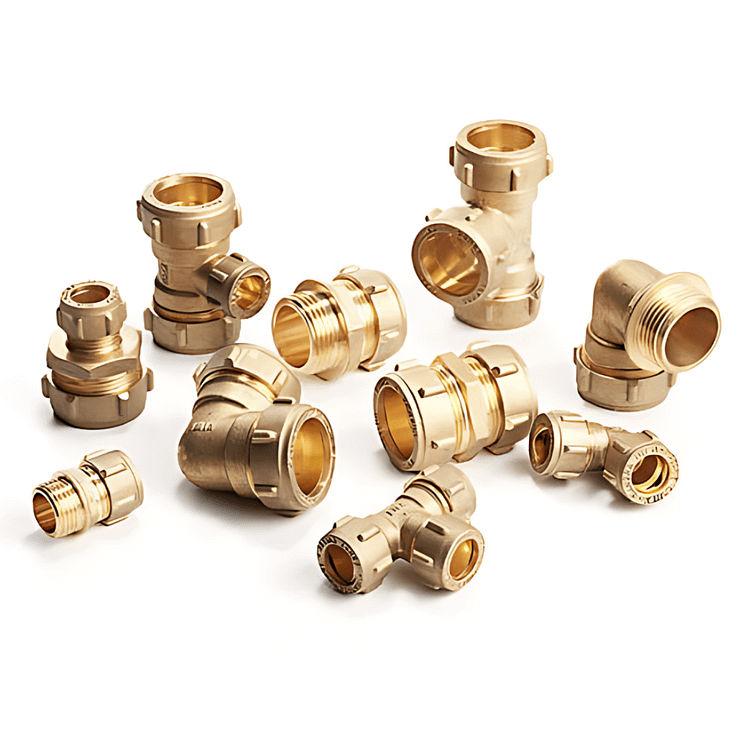

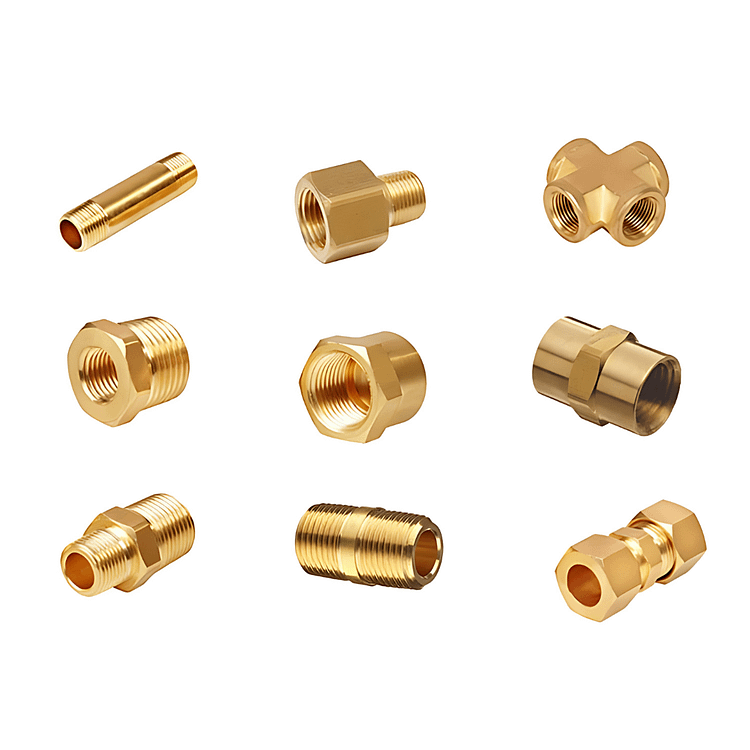

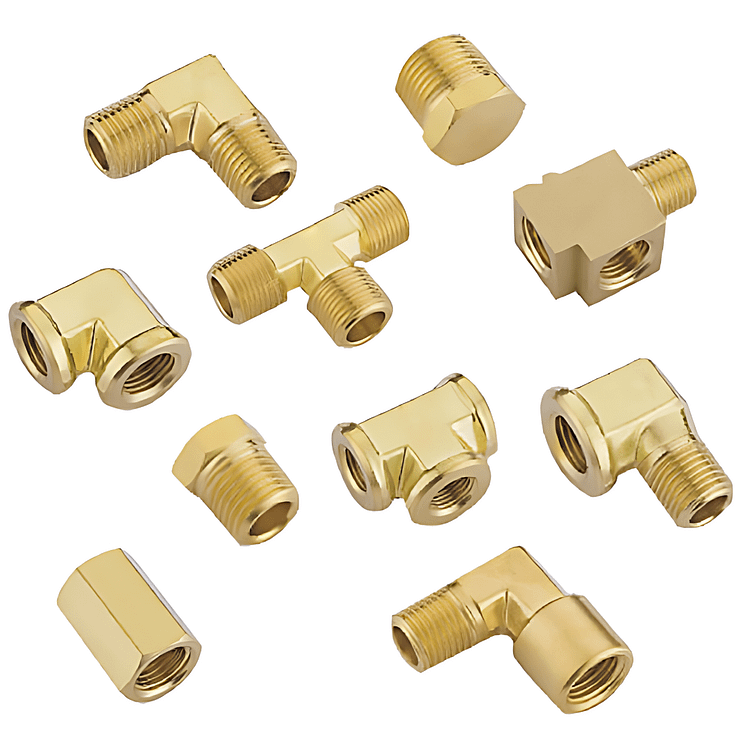

Different Kinds of Brass Fittings

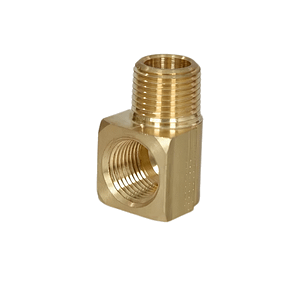

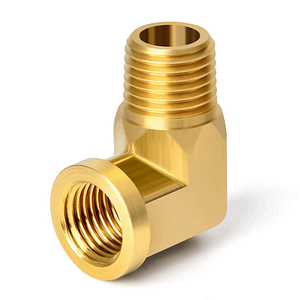

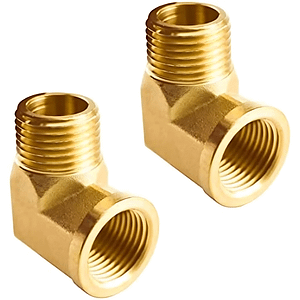

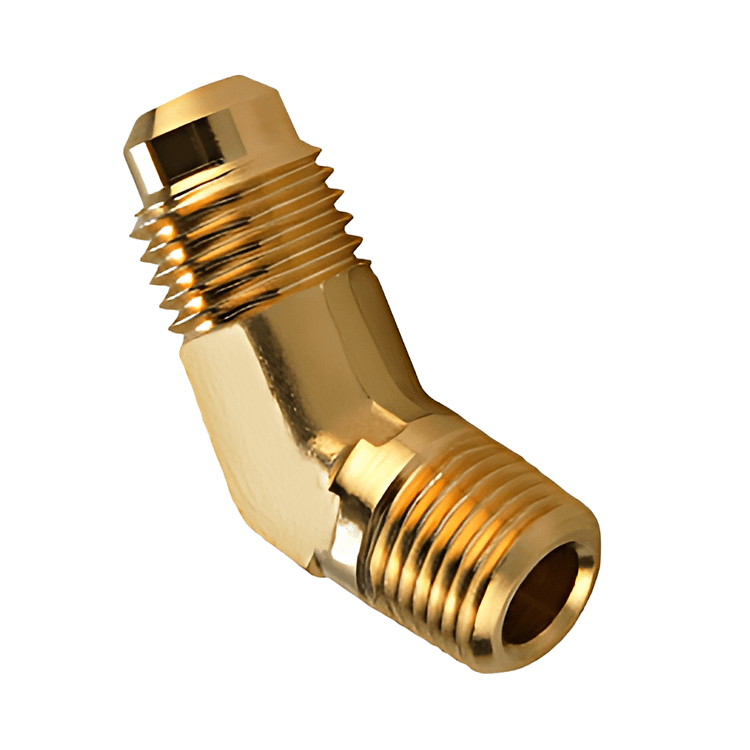

Brass fittings come in various types, each designed for specific purposes in different systems. Elbows are one of the most common types, used to change the direction of flow in a piping system. They are available in several angles, including 45 degrees and 90 degrees, to accommodate different routing needs.

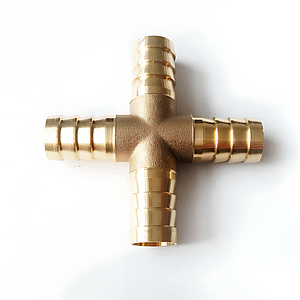

Tee fittings are essential for splitting or combining flow. Shaped like the letter T, they have one inlet and two outlets, or vice versa, allowing for efficient distribution or collection of fluids. Couplings are used to connect two pipes of the same diameter. They can be straight, connecting pipes of the same size, or reducing, which connects pipes of different diameters, making them versatile for various connection requirements.

Adapters are crucial when there is a need to connect pipes or fittings with different end types or sizes. They can convert connections from male to female, threaded to non-threaded, or adapt different fitting types, ensuring compatibility within the system. Unions are similar to couplings but are designed to allow easy disconnection and reconnection of pipes, which is particularly useful in systems requiring regular maintenance.

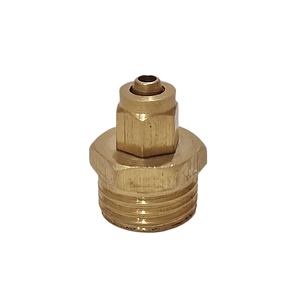

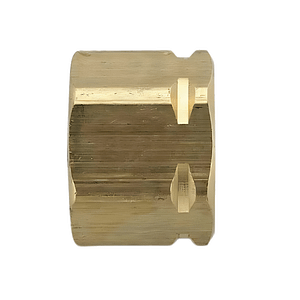

Bushings are another type of brass fitting used to reduce the size of a pipe opening to fit pipes of different diameters. This adaptability makes them useful in systems where piping dimensions need to be adjusted.

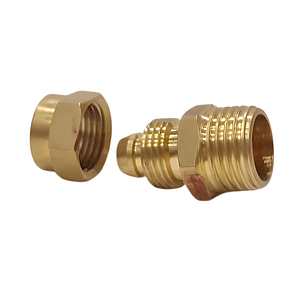

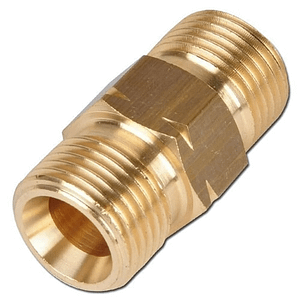

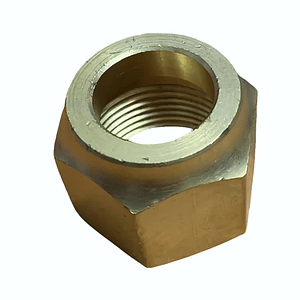

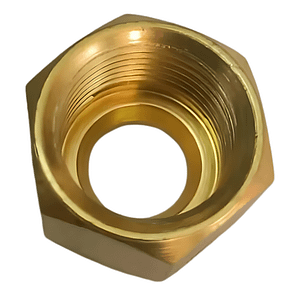

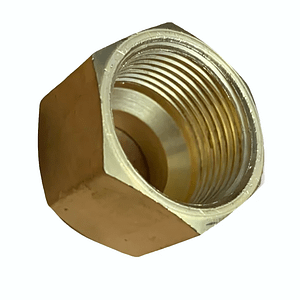

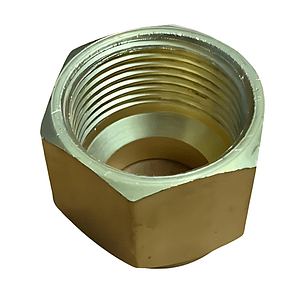

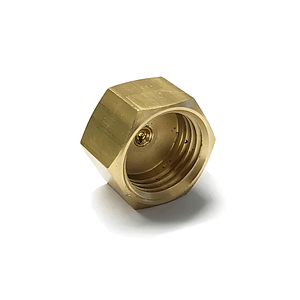

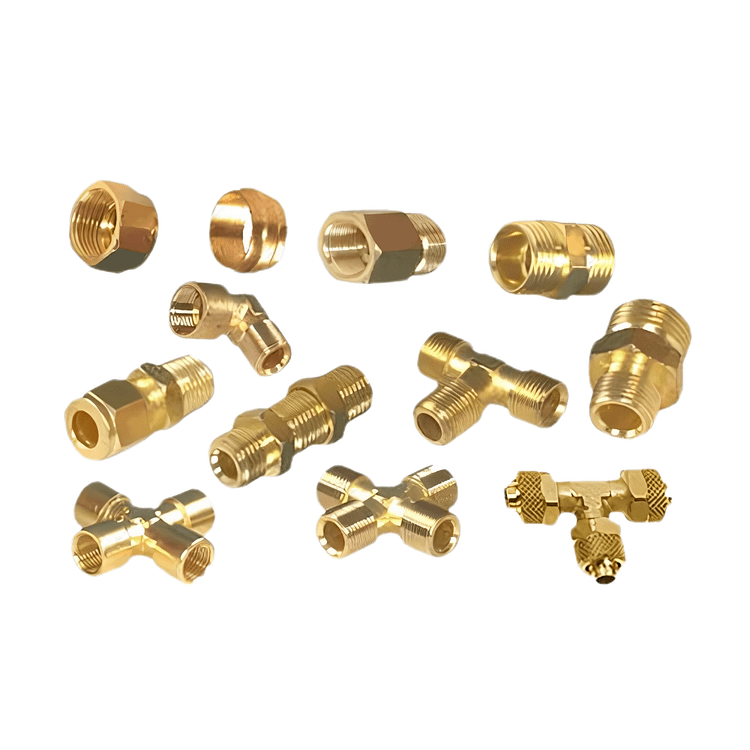

Brass Flare and Union Fittings

Brass flare fittings and union fittings are specialized types of brass fittings with unique applications. Flare fittings are typically used in high-pressure environments, such as refrigeration and gas systems. They create a robust seal by flaring the end of a pipe or tubing, which is then compressed against a fitting body, providing a leak-free connection that can withstand significant pressure.

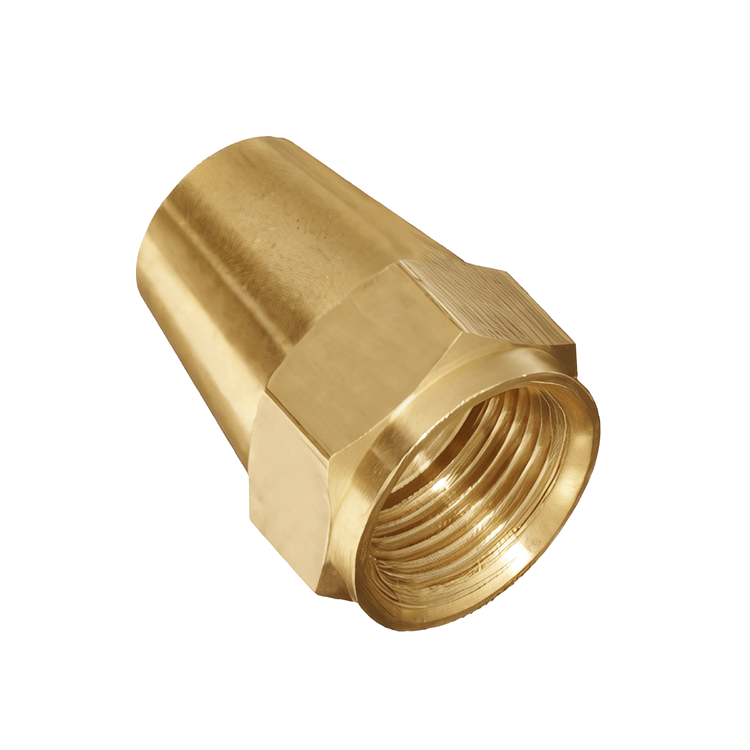

Union fittings, on the other hand, are designed for systems that require frequent disassembly and reassembly. They consist of three parts: a nut, a female end, and a male end. The nut tightens the female and male ends together, allowing for a secure connection that can be easily undone when necessary. This makes union fittings ideal for maintenance-heavy applications.

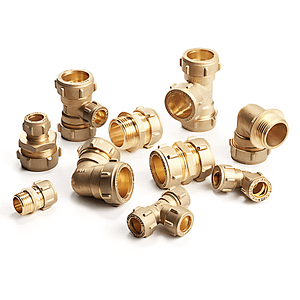

Brass Fittings Customization

Customization of brass fittings is an important aspect for many industries. Brass’s malleability and machinability make it an excellent material for custom fittings tailored to specific requirements. Custom brass fittings can be manufactured to precise specifications, accommodating unique shapes, sizes, and threading to meet the needs of specialized applications.

Industries such as automotive, manufacturing, and even home decor benefit from customized brass fittings. For example, in the automotive industry, custom fittings are used in fuel systems, brake systems, and cooling systems, ensuring optimal performance and compatibility. In manufacturing, custom brass fittings can be designed to handle specific chemical reactions or fluid dynamics, enhancing the efficiency and safety of industrial processes. In home decor, custom brass fittings add a touch of elegance and functionality to plumbing fixtures and decorative elements, aligning with aesthetic and practical requirements.

In conclusion, brass fittings offer numerous benefits, including corrosion resistance, durability, malleability, and thermal conductivity. They come in various types to meet different system requirements, and specialized fittings like flare and union fittings serve unique applications. The ability to customize brass fittings further enhances their versatility and functionality across diverse industries.