Brass Fasteners by BOLTORQ Brassmet: The Ultimate Guide

What Are Brass Fasteners? Professional Hardware for Superior Performance

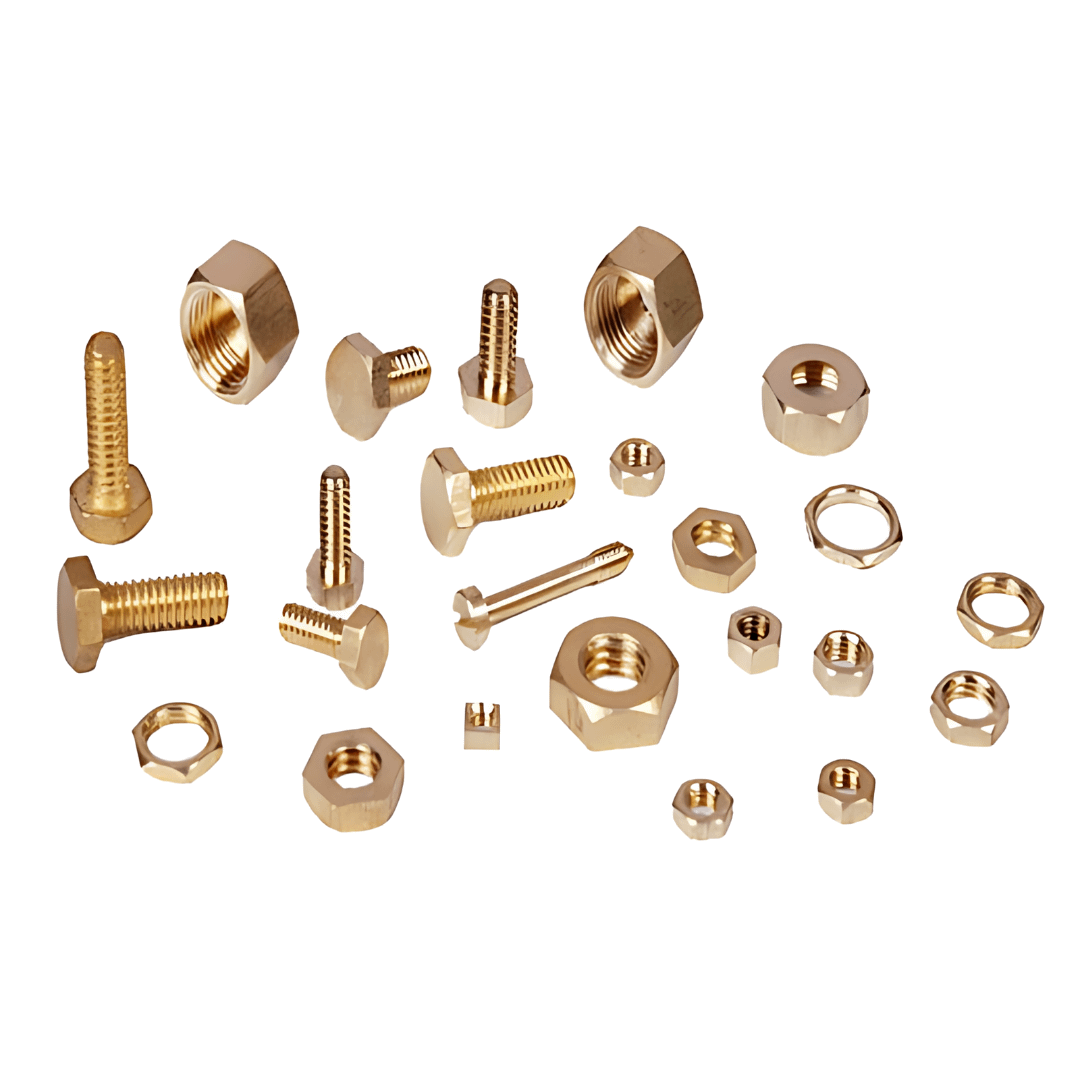

Brass fasteners are precision-engineered mechanical hardware components manufactured from copper-zinc alloys, designed to join, secure, and assemble materials across industrial, commercial, and residential applications. These corrosion-resistant fasteners include brass screws, bolts, nuts, washers, rivets, and anchors that deliver exceptional performance in demanding environments.

Engineers, contractors, manufacturers, and procurement specialists worldwide choose brass fasteners for their unique combination of mechanical strength, electrical conductivity, corrosion resistance, and aesthetic appeal in applications ranging from marine equipment to electrical assemblies.

Why Brass Fasteners Are Essential for Modern Applications

Superior Material Properties of Brass Fastening Hardware

Exceptional Corrosion Resistance

Brass fasteners demonstrate outstanding resistance to atmospheric corrosion, saltwater exposure, and chemical attack. The protective patina that forms on brass surfaces provides self-healing corrosion protection, making these fasteners ideal for marine environments, outdoor installations, coastal construction, and chemical processing facilities.

High Mechanical Strength and Durability

Engineering-grade brass alloys (CuZn37, CuZn39Pb3) provide tensile strengths ranging from 300-550 MPa, ensuring reliable load-bearing capacity and fatigue resistance through thousands of tightening cycles without thread degradation or mechanical failure.

Excellent Electrical and Thermal Conductivity

With electrical conductivity approximately 28% IACS (International Annealed Copper Standard) and thermal conductivity of 120 W/m·K, brass fasteners excel in electrical grounding applications, heat dissipation assemblies, and conductive pathways in power distribution systems.

Premium Aesthetic Appearance

The distinctive golden luster of brass fasteners provides a professional, high-quality finish for visible applications including architectural hardware, marine fittings, decorative assemblies, antique restoration, and premium furniture manufacturing.

Superior Machinability and Formability

Brass alloys offer exceptional machinability ratings (80-90% relative to free-cutting steel), enabling production of complex thread geometries, precise dimensions, intricate head designs, and custom fastener configurations with minimal tool wear.

Non-Magnetic and Non-Sparking Properties

Brass fasteners are completely non-magnetic, making them essential for MRI equipment, navigation instruments, electronic devices, and scientific apparatus. Their non-sparking characteristics ensure safety in explosive atmospheres and hazardous environments.

BOLTORQ Brassmet: Leading Brass Fastener Manufacturer in Jamnagar

BOLTORQ Brassmet has established itself as a trusted name in the manufacturing of brass components. Here’s why BOLTORQ Brassmet stands out in the brass fasteners market:

- High-Quality Materials: BOLTORQ Brassmet uses premium-grade brass to ensure the durability and reliability of their fasteners.

- Precision Engineering: Their components are manufactured with exacting precision to meet stringent requirements.

- Wide Range: BOLTORQ Brassmet offers a variety of brass fasteners tailored to different needs and specifications.

- Rigorous Testing: Each product undergoes extensive testing to ensure it meets or exceeds industry standards for performance and safety.

- Customer Support: BOLTORQ Brassmet provides exceptional customer service, helping clients select the right components for their specific applications.

Types of Brass Fasteners by BOLTORQ Brassmet

1. Brass Screws – Versatile Threaded Fastening Solutions

Precision-manufactured brass screws featuring various head styles (flat, round, pan, oval, hex, socket), drive types (slotted, Phillips, Pozidriv, Torx, hex socket), and thread profiles for diverse fastening applications.

Industrial Applications:

- Electrical switchgear and control panels

- Marine hardware and deck fittings

- Electronic equipment assembly

- Musical instrument manufacturing

- Furniture and cabinetry hardware

- Automotive interior components

- HVAC system installations

Available Configurations:

- Head Styles: Flat head, round head, pan head, oval head, hex head, socket head, button head, truss head

- Drive Types: Slotted, Phillips (PH), Pozidriv (PZ), Torx (T), hex socket, square drive

- Thread Types: Machine screw threads, wood screw threads, self-tapping, thread-forming

- Sizes: M1.6 to M12 (metric), #0-80 to 1/2″-13 (imperial)

- Lengths: 3mm to 150mm available

Technical Specifications:

- Tensile strength: 300-500 MPa depending on alloy

- Hardness: 70-120 HV (Vickers)

- Torque capacity: 0.5-25 Nm based on size

- Corrosion resistance: 500+ hours salt spray per ASTM B117

2. Brass Bolts – Heavy-Duty Fastening Solutions

High-strength brass bolts engineered for structural connections, machinery assembly, and heavy-duty applications requiring superior load-bearing capacity and vibration resistance.

Primary Applications:

- Structural construction and steel fabrication

- Industrial machinery and equipment

- Automotive engine assemblies

- Marine propulsion systems

- Pump and valve assemblies

- Pressure vessel connections

- Railway infrastructure

Product Specifications:

- Head Types: Hex head, square head, carriage, T-bolt, eye bolt, U-bolt

- Thread Standards: ISO metric coarse/fine, UNC/UNF, BSW/BSF

- Grades: Standard brass (CuZn37), high-strength brass (CuZn40), lead-free brass

- Sizes: M3 to M24 (metric), 1/4″ to 1″ (imperial)

- Lengths: 10mm to 300mm

Performance Characteristics:

- Proof load: 60-70% of tensile strength

- Shear strength: 200-400 MPa

- Temperature range: -40°C to +200°C

- Thread accuracy: ISO 965-2 Class 6g/6H

- Vibration resistance: DIN 267 Part 27 compliant

3. Brass Nuts – Precision Threaded Components

High-precision brass nuts manufactured to exact thread tolerances, available in multiple configurations including standard hex nuts, lock nuts, wing nuts, and specialty designs.

Common Applications:

- Plumbing systems and pipe connections

- Electrical conduit and junction boxes

- Pneumatic and hydraulic assemblies

- Industrial machinery fastening

- Automotive transmission systems

- Musical instruments and hardware

- Scientific and laboratory equipment

Configuration Options:

- Styles: Hex nut, square nut, wing nut, cap nut, dome nut, flange nut, coupling nut, lock nut

- Thread Types: ISO metric, UNC/UNF, BSW/BSF, NPT/BSPT for pipe threads

- Sizes: M1.6 to M24 (metric), #0-80 to 1″ (imperial)

- Height: Standard, thin (jam nut), thick, extra-thick

- Locking Features: Nylon insert, metal prevailing torque, serrated flange

Quality Features:

- Thread tolerance: ISO 965-2 Class 6H

- Hexagon tolerance: ISO 4032/4033

- Load capacity: Grade 4, 5, or 8 equivalent

- Surface finish: Natural brass, nickel-plated, tin-plated

- Traceability: Lot codes for quality tracking

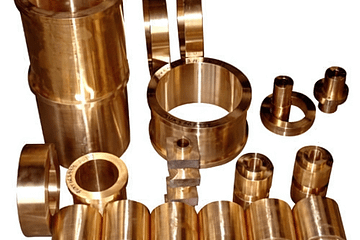

4. Brass Washers – Load Distribution Components

Precision brass washers designed to distribute fastener loads, prevent surface damage, provide electrical insulation, and ensure proper tension in bolted assemblies.

Application Sectors:

- Electronic circuit boards and assemblies

- Automotive electrical systems

- Marine equipment installations

- Architectural curtain walls

- HVAC equipment mounting

- Pressure vessel flanges

- Solar panel installations

Washer Types:

- Flat Washers: Standard (DIN 125, ISO 7089), large OD, extra-large, fender washers

- Spring Washers: Split lock (DIN 127), wave washers, Belleville disc springs

- Specialty Washers: Shoulder washers, finishing washers, sealing washers, star washers

- Sizes: M2 to M24 (metric), #2 to 1″ (imperial)

- Thickness: 0.5mm to 5mm

Engineering Benefits:

- Load distribution: 200-500% surface area increase

- Anti-vibration: Spring washers reduce loosening

- Electrical isolation: Prevents galvanic corrosion

- Surface protection: Prevents marring of finished surfaces

- Thermal expansion compatibility: Matches brass fasteners

5. Brass Rivets – Permanent Fastening Solutions

Solid, semi-tubular, and blind brass rivets providing permanent mechanical joints for applications where welding is impractical, aesthetics matter, or dissimilar materials require joining.

Industrial Applications:

- Aircraft interior assemblies (non-structural)

- Leather goods and luggage manufacturing

- Sheet metal fabrication

- Electrical enclosure assembly

- Jewelry and decorative hardware

- Musical instrument construction

- Historical restoration projects

Rivet Classifications:

- Solid Rivets: Round head, flat head, countersunk, brazier head

- Semi-Tubular Rivets: Standard, oval head, truss head

- Blind Rivets: Pop rivets with brass mandrel

- Drive Rivets: Hammer-set installation

- Sizes: 1.5mm to 12mm diameter, 3mm to 50mm length

Installation Specifications:

- Installation methods: Pneumatic, manual, automatic feed systems

- Grip range: 2mm to 25mm depending on type

- Shear strength: 150-400 MPa

- Tensile strength: 200-500 MPa

- Head styles: Flush, protruding, decorative

6. Brass Anchors (Brass Unifix) – Structural Mounting Solutions

High-holding-power brass anchors for secure mounting in concrete, brick, stone, drywall, and hollow wall applications, providing reliable load transfer in construction and installation projects.

Construction Applications:

- Electrical panel mounting

- HVAC equipment installation

- Architectural fixture attachment

- Marine dock hardware

- Industrial shelving systems

- Seismic-rated connections

- Facade and cladding systems

Anchor Types:

- Expansion Anchors: Wedge anchors, sleeve anchors, drop-in anchors

- Screw Anchors: Self-drilling, self-tapping concrete screws

- Hollow Wall Anchors: Toggle bolts, molly bolts, snap toggles

- Adhesive Anchors: Chemical anchor systems with brass rods

- Sizes: M6 to M20, load ratings 50kg to 5000kg

Performance Ratings:

- Pull-out strength: 2kN to 50kN depending on size and substrate

- Shear capacity: 1.5kN to 40kN

- Safety factors: 4:1 minimum per ICC-ES standards

- Corrosion resistance: Suitable for exterior use

- Installation standards: Per ASTM E488, ACI 318

Key Features and Benefits of BOLTORQ Brassmet’s Brass Fasteners

1. Engineering-Grade Durability and Longevity

BOLTORQ brass fasteners deliver operational lifespans exceeding 20-30 years in marine environments and 50+ years in interior applications, with documented failure rates below 0.05% under specified load conditions.

2. Superior Corrosion Protection Performance

Accelerated corrosion testing demonstrates 1000+ hour neutral salt spray resistance per ASTM B117, 720+ hour acidic salt spray per ASTM G85-A3, and excellent performance in dezincification testing per ISO 6509 and ASTM D2036.

3. Precision Thread Manufacturing

ISO 965 Class 6g/6H thread tolerances ensure perfect mating with standard nuts and tapped holes, eliminating cross-threading, reducing assembly torque variation to ±5%, and enabling automated assembly processes.

4.Non-Sparking and Non-Magnetic Properties

Brass fasteners provide essential safety in explosive atmospheres (ATEX/IECEx zones), petrochemical facilities, grain handling, and environments where magnetic interference affects sensitive instruments or MRI equipment.

5. Low-Friction Installation Characteristics

Natural lubricity of brass reduces installation torque by 15-25% compared to steel, minimizes galling and seizing, enables higher preload accuracy, and extends tool life in automated assembly operations.

6. Electrical Grounding and EMI Shielding

Conductivity at 28% IACS provides reliable electrical paths for grounding systems, lightning protection, static discharge, and electromagnetic interference (EMI) shielding in sensitive electronic environments.

The Manufacturing Excellence of BOLTORQ Brassmet

Material Selection

BOLTORQ Brassmet begins with high-quality brass, ensuring that their fasteners possess the necessary mechanical and physical properties. The alloy composition is carefully controlled to achieve the desired balance of strength, corrosion resistance, and conductivity.

Precision Machining

Advanced machining processes are used to manufacture brass fasteners to precise dimensions and tolerances. This ensures a perfect fit and reliable performance in their intended applications.

Surface Finishing

Surface finishing techniques such as polishing, plating, and coating enhance the appearance and corrosion resistance of the fasteners. This not only improves their aesthetic appeal but also extends their service life.

Quality Control

Every brass fastener undergoes stringent quality control measures, including dimensional inspections, performance evaluations, and durability testing, to ensure they meet the highest industry standards.

Custom Solutions

BOLTORQ Brassmet is committed to innovation and offers custom solutions tailored to specific client requirements. Whether it’s a unique fastener design or a special alloy composition, BOLTORQ Brassmet can provide components that meet the most demanding applications.

Applications of Brass Fasteners

Construction

In the construction industry, brass fasteners such as bolts, screws, and anchors are used to secure structural elements and ensure the stability of buildings and infrastructure. Their strength and corrosion resistance are crucial in this demanding environment.

Automotive

Brass fasteners in the automotive industry ensure secure and durable connections in various components, from engine parts to interior panels. Their strength and corrosion resistance are critical in this demanding environment.

Electronics

Brass fasteners are used in electronics to secure components within devices and enclosures. Their excellent conductivity and corrosion resistance make them ideal for these applications.

Marine

In the marine industry, brass fasteners such as screws, bolts, and rivets are used to secure components exposed to harsh marine environments. Their corrosion resistance ensures long-term performance and reliability.

Industrial Machinery

Brass fasteners are used in industrial machinery to provide secure and durable connections. This includes nuts, bolts, and washers that enhance the efficiency and durability of the machinery.

Home Improvement

In home improvement projects, brass fasteners are used for tasks such as securing fixtures, assembling furniture, and attaching decorative elements. Their aesthetic appeal and corrosion resistance make them a popular choice for homeowners.

Environmental and Safety Considerations

Sustainability

BOLTORQ Brassmet is dedicated to sustainable manufacturing practices. Brass is a recyclable material, and the company ensures that waste is minimized during production. Their products are designed for long-term use, reducing the need for frequent replacements and contributing to environmental conservation.

Safety Standards

All brass fasteners by BOLTORQ Brassmet comply with international safety standards, ensuring they provide reliable protection and performance in their intended applications. Their components are tested for durability and safety, making them a trustworthy choice for manufacturers.

Conclusion

Brass fasteners by BOLTORQ Brassmet represent the pinnacle of quality, durability, and performance in the manufacturing industry. With a comprehensive range of products designed to meet various applications, BOLTORQ Brassmet has become a trusted name in the field. Their commitment to precision engineering, quality assurance, and customer satisfaction ensures that their brass fasteners are not only reliable but also built to last. Whether you’re working on a construction project, automotive assembly, or electronics application, BOLTORQ Brassmet has the right brass fasteners to meet your needs.

Explore the Range of BOLTORQ Brassmet Brass Fasteners

To learn more about BOLTORQ Brassmet and their extensive range of brass fasteners, visit their website or contact their customer service team. Experience the quality and reliability that only BOLTORQ Brassmet can provide.

FAQs

1. What are the main benefits of using brass fasteners?

Brass fasteners offer excellent durability, corrosion resistance, and high thermal and electrical conductivity. They provide reliable and long-lasting performance in various applications.

2. Can brass fasteners be used in high-temperature environments?

Yes, brass has excellent thermal conductivity and can withstand high temperatures, making it suitable for use in applications requiring heat dissipation.

3. How do I choose the right brass fastener for my application?

Consider factors such as the type of material, environmental conditions, and specific requirements of your application. Consulting with BOLTORQ Brassmet’s customer service can also help you make the right choice.

4. Are BOLTORQ Brassmet fasteners environmentally friendly?

Yes, brass is a recyclable material, and BOLTORQ Brassmet employs sustainable manufacturing practices to minimize waste and environmental impact.

5. Do brass fasteners require special maintenance?

Brass fasteners are low-maintenance but should be regularly inspected for any signs of wear or damage. Cleaning them periodically will help maintain their appearance and performance.

By choosing BOLTORQ Brassmet, you are investing in fasteners that combine quality, durability, and exceptional performance, ensuring the success of your projects for years to come.

See more about out our products:

Brass Fitting Parts by BOLTORQ Brassmet: A Comprehensive Guide

Brass Cable Glands by BOLTORQ Brassmet: A Comprehensive Guide

Brass Auto Parts by BOLTORQ Brassmet: Driving Excellence in Automotive Components

Brass Inserts by BOLTORQ Brassmet: The Ultimate Guide

Brass Turned Components by BOLTORQ Brassmet: Precision, Quality, and Reliability

0 Comments