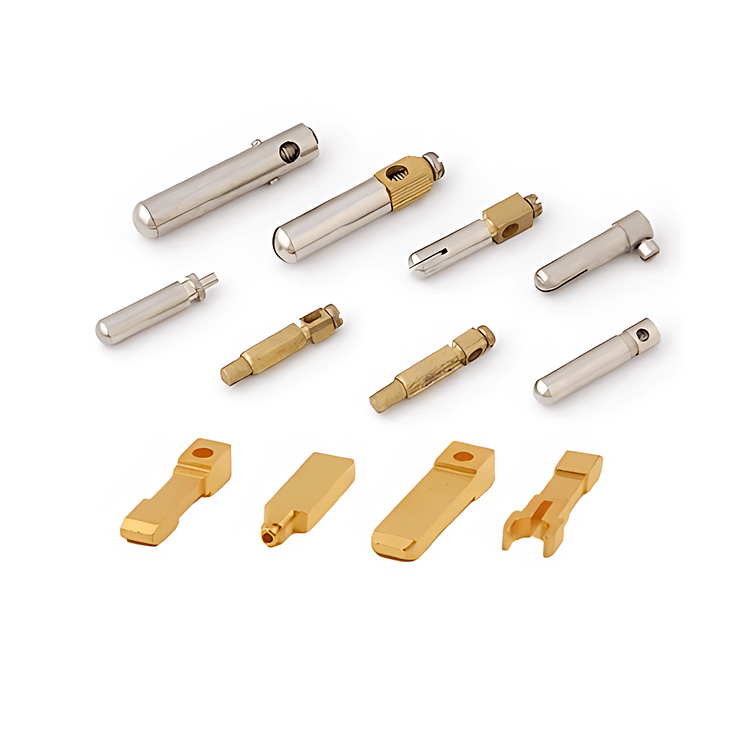

Brass Contact Pin Sockets

Brass contact pin sockets are essential components in electrical and electronic systems, designed to provide reliable and efficient connections between circuit elements. Known for their durability, excellent conductivity, and resistance to corrosion, these sockets ensure stable performance in a variety of applications. Here, we explore the key benefits and uses of brass contact pin sockets.

Durability and Strength

Brass contact pin sockets are valued for their durability and strength. Made from a robust copper and zinc alloy, these sockets can withstand significant mechanical stress without deforming or breaking. This durability ensures long-lasting performance, making them ideal for use in demanding electrical environments.

Excellent Conductivity

One of the primary reasons brass is chosen for contact pin sockets is its excellent electrical conductivity. Brass provides efficient energy transfer, which is crucial for maintaining the performance and reliability of electrical connections. This makes brass sockets perfect for applications requiring stable and low-resistance electrical pathways.

Corrosion Resistance

Brass offers superior resistance to corrosion, an important feature for contact pin sockets exposed to moisture and various environmental conditions. Unlike other metals that may corrode or rust, brass maintains its integrity, ensuring consistent performance over time. This property is particularly valuable in outdoor or industrial applications where exposure to the elements is common.

Versatility in Applications

The versatility of brass allows it to be used in a wide range of applications. Brass contact pin sockets are found in consumer electronics, industrial machinery, automotive systems, and telecommunications equipment. Their adaptability makes them suitable for connecting various electronic components, ensuring reliable performance in complex systems.

Precision and Stability

Brass contact pin sockets are designed to provide precise and stable connections. Their excellent machining properties allow for the creation of sockets with tight tolerances, ensuring a secure fit with contact pins. This precision is crucial in maintaining the stability and integrity of electrical connections, especially in high-frequency or high-current applications.

Easy Machinability

Brass is highly machinable, allowing for the production of contact pin sockets with precise specifications. This ease of machining ensures that brass sockets can be tailored to meet specific design requirements, providing customized solutions for unique applications. The ability to produce high-quality, detailed components enhances the overall functionality of electrical and electronic systems.

Thermal Conductivity

Brass exhibits excellent thermal conductivity, which is beneficial for contact pin sockets that must handle varying levels of electrical current. This property allows brass sockets to dissipate heat efficiently, preventing overheating and potential damage to electrical components. Thermal management is critical in ensuring the longevity and reliability of electronic devices.

Environmental Sustainability

Brass is an environmentally sustainable material due to its recyclability. Using recycled brass in the production of contact pin sockets helps conserve natural resources and reduce environmental impact. The long lifespan and durability of brass components also contribute to sustainability by minimizing waste and the need for frequent replacements.

Easy Installation and Maintenance

Brass contact pin sockets are easy to install and maintain, which simplifies their use in various applications. Their durability and resistance to corrosion mean they require minimal maintenance, ensuring reliable performance with less effort. This ease of use makes brass sockets a practical choice for both large-scale industrial projects and everyday electronic repairs.

Conclusion

Brass contact pin sockets offer a unique combination of durability, conductivity, corrosion resistance, and versatility. These properties make them suitable for a wide range of electrical and electronic applications, from consumer electronics to industrial machinery. By incorporating brass sockets into their designs, manufacturers can ensure the creation of reliable, efficient, and long-lasting electrical connections.