Brass Casting and Forging

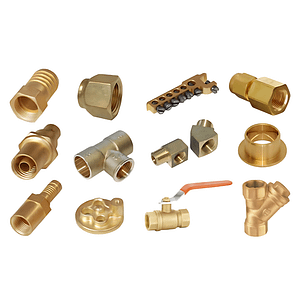

Brass casting and forging are two distinct manufacturing processes used to create high-quality brass components with different characteristics and applications. While both methods involve shaping brass into desired forms, they each offer unique advantages and are chosen based on specific requirements such as strength, complexity, and cost-effectiveness. Let’s explore how brass casting and forging contribute to the production of durable and precise brass parts.

Brass Casting: Forming Complex Shapes with Versatility

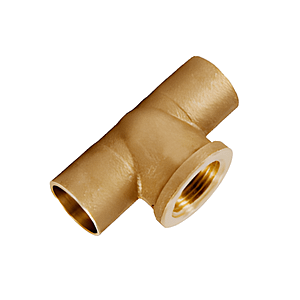

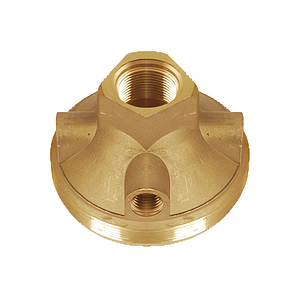

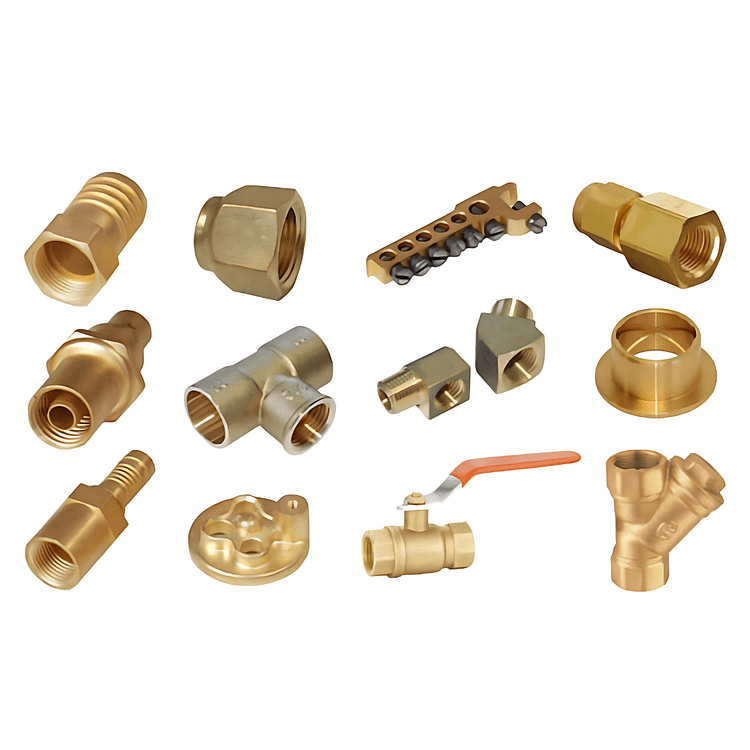

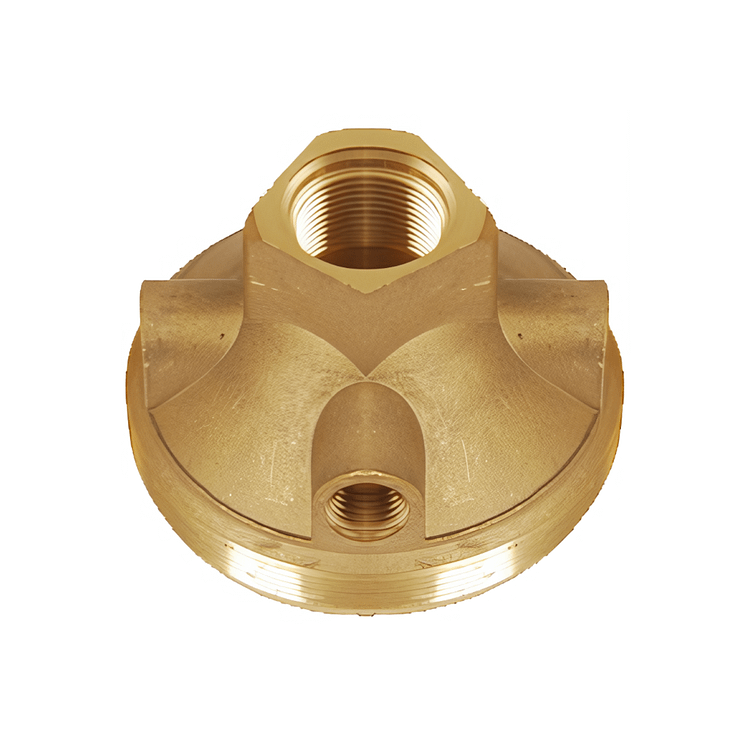

Brass casting involves pouring molten brass into a mold to create a desired shape. This process offers versatility in manufacturing as it allows for the production of intricate and complex shapes with fine details. Brass casting is particularly suitable for components with intricate geometries, irregular shapes, or decorative elements, such as ornamental fixtures, architectural hardware, and artistic sculptures. The flexibility of brass casting enables the creation of custom designs tailored to specific aesthetic or functional requirements, making it a preferred method for producing unique and visually striking brass components.

Brass Forging: Achieving Strength and Durability through Precision

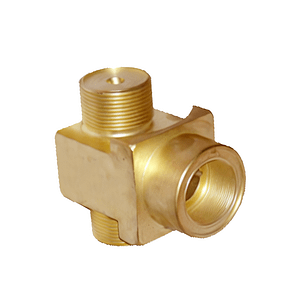

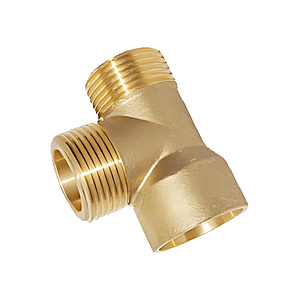

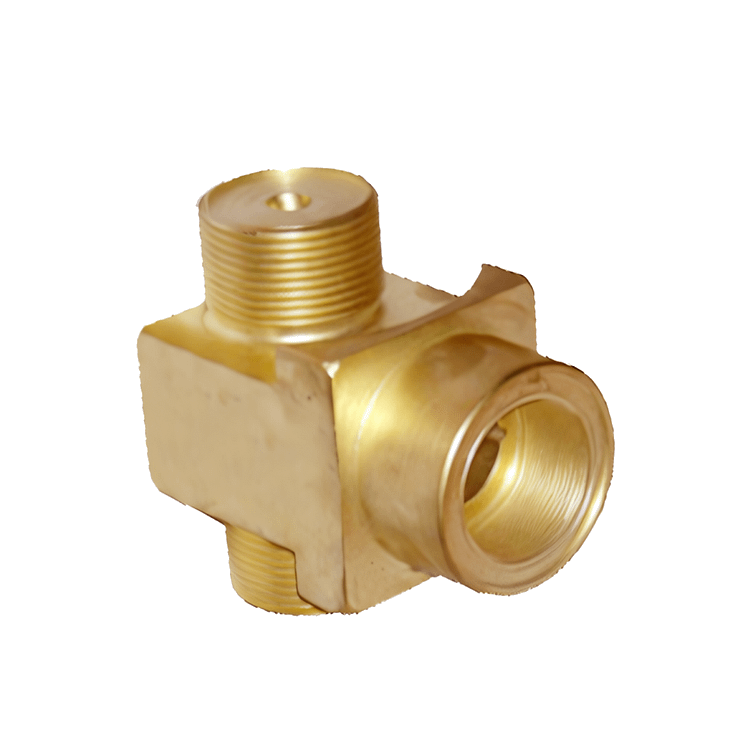

Brass forging is a manufacturing process that involves shaping solid brass billets or bars through controlled deformation under high pressure and temperature. This method produces parts with superior mechanical properties, including increased strength, toughness, and fatigue resistance. Brass forging is ideal for creating components that require high strength-to-weight ratios, precise dimensions, and structural integrity, such as automotive parts, industrial fittings, and tooling components. The precision and consistency achieved through forging ensure that brass parts meet strict performance standards and withstand demanding operating conditions, making them reliable and long-lasting solutions for various applications.

Comparative Advantages and Considerations

While both brass casting and forging offer unique advantages, the choice between the two methods depends on factors such as component design, material properties, production volume, and cost considerations. Brass casting excels in producing complex shapes with intricate details and is well-suited for low to medium volume production runs. On the other hand, brass forging delivers superior strength and mechanical properties, making it ideal for parts subjected to heavy loads or harsh environments. However, forging typically requires more extensive tooling and setup costs, making it more suitable for high-volume production and cost-sensitive applications.

Application Areas and Industry Use

Brass casting and forging find application across various industries, including automotive, aerospace, construction, marine, and manufacturing. Brass castings are commonly used in decorative and architectural applications, plumbing fixtures, artistic sculptures, and ornamental hardware. Brass forgings, on the other hand, are prevalent in critical components such as valves, fittings, fasteners, gears, and electrical connectors, where strength, reliability, and precision are paramount. By leveraging the unique capabilities of both casting and forging processes, manufacturers can produce a wide range of brass components tailored to specific industry needs and performance requirements.

Combining Craftsmanship and Technology

In conclusion, brass casting and forging are indispensable manufacturing processes that contribute to the production of high-quality brass components with distinct properties and applications. While casting offers versatility and design flexibility for creating intricate shapes and decorative elements, forging delivers strength, durability, and precision for producing robust and reliable parts. By harnessing the capabilities of both processes, manufacturers can meet the diverse demands of modern industries while upholding the tradition of craftsmanship and excellence in brass manufacturing.