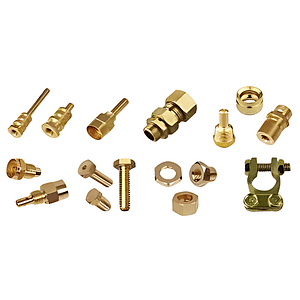

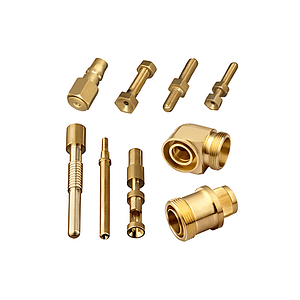

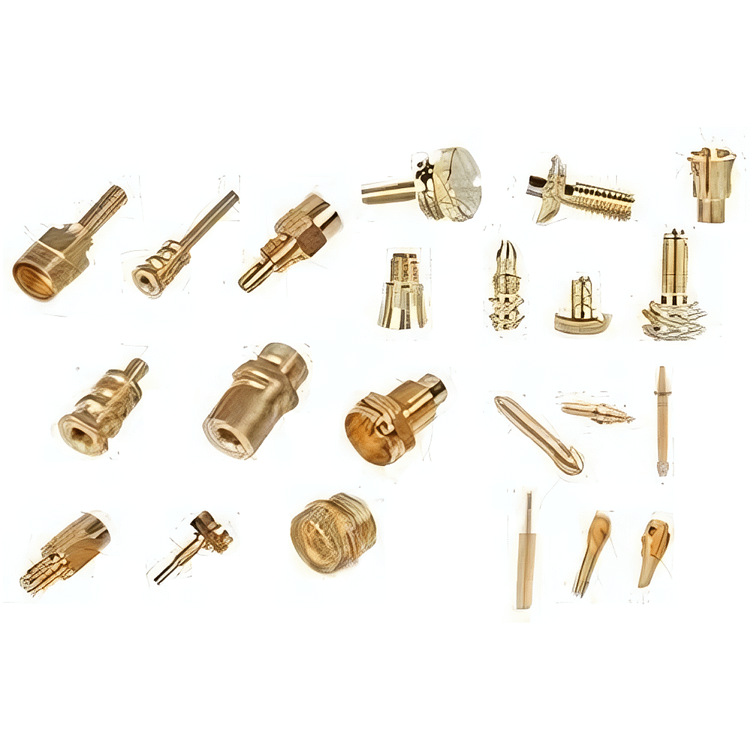

Brass Auto Parts

Brass auto parts play a crucial role in the automotive industry, known for their exceptional durability, precision, and reliability. These components are integral to the performance and safety of vehicles, making brass a preferred material for a wide range of automotive applications. From fuel systems to electrical components, brass auto parts ensure that vehicles operate efficiently and effectively.

Durability and Strength

One of the primary reasons brass is favored in the automotive industry is its outstanding durability. Brass is an alloy composed of copper and zinc, which imparts significant strength and resistance to wear and tear. This makes brass auto parts ideal for applications that experience high levels of stress and friction, such as engine components, bearings, and transmission parts. The durability of brass ensures that these parts have a long service life, reducing the frequency of replacements and maintenance.

Corrosion Resistance

Brass auto parts are also highly resistant to corrosion. This is particularly important in the automotive industry, where components are often exposed to harsh environmental conditions, including moisture, road salt, and various chemicals. The corrosion resistance of brass helps prevent rust and degradation, ensuring the longevity and reliability of automotive components. This property is especially beneficial for parts used in fuel systems, braking systems, and cooling systems, where exposure to corrosive substances is common.

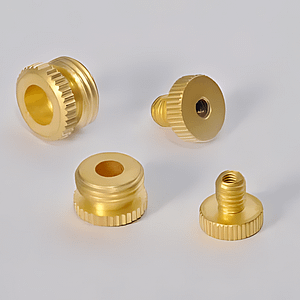

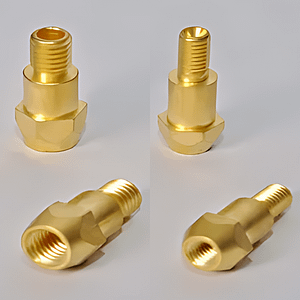

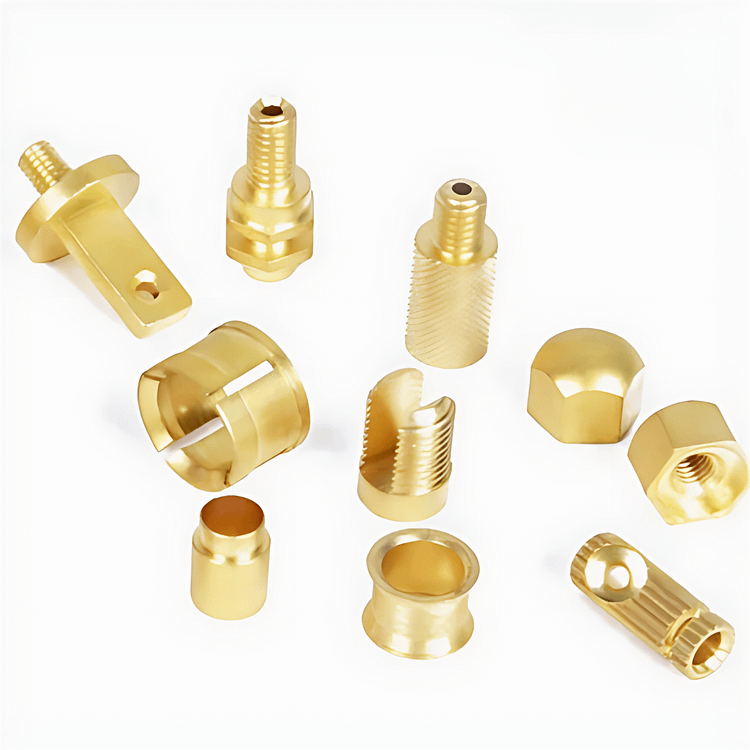

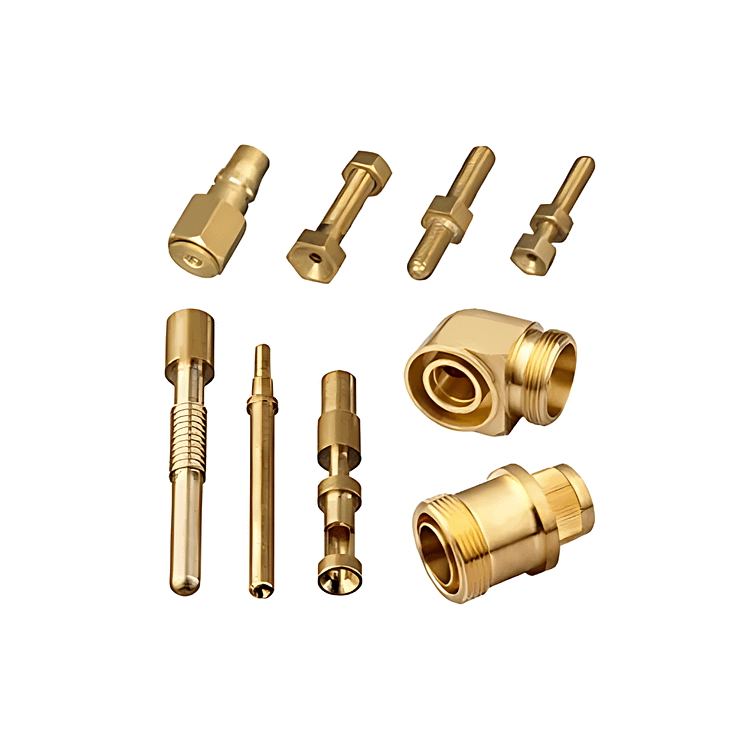

Precision and Machinability

Precision is paramount in automotive engineering, and brass excels in this regard. The machinability of brass allows for the production of highly precise and intricate components, essential for modern vehicles’ complex systems. CNC (Computer Numerical Control) machining and other advanced manufacturing techniques enable the creation of brass auto parts with tight tolerances and detailed geometries. This precision ensures that components fit together perfectly, contributing to the overall efficiency and performance of the vehicle.

Thermal and Electrical Conductivity

Brass has excellent thermal and electrical conductivity, making it suitable for a variety of automotive applications. In electrical systems, brass is used for connectors, terminals, and various electrical components due to its superior conductivity and resistance to electrical corrosion. In terms of thermal properties, brass is used in radiators, heat exchangers, and other cooling system components where efficient heat transfer is crucial.

Versatility in Applications

The versatility of brass allows it to be used in a wide range of automotive applications. In fuel systems, brass components such as fuel injectors and fittings ensure reliable fuel delivery and combustion. In braking systems, brass parts provide the necessary strength and precision for effective braking performance. Brass is also used in transmission systems, HVAC (heating, ventilation, and air conditioning) components, and various engine parts, highlighting its adaptability across different automotive functions.

Sustainability and Recyclability

Brass is a sustainable material due to its recyclability, which is increasingly important in the automotive industry’s push towards greener practices. Recycled brass maintains its properties and performance, reducing waste and conserving resources. This aligns with the industry’s goals to minimize environmental impact and promote sustainable manufacturing practices.

Conclusion

Brass auto parts are indispensable in the automotive industry, offering durability, precision, and reliability. Their resistance to corrosion, excellent machinability, and superior thermal and electrical conductivity make them ideal for a wide range of applications, from fuel and braking systems to electrical components and cooling systems. The versatility of brass, combined with its sustainability, ensures that brass auto parts continue to be a vital component in automotive engineering. As the industry evolves and the demand for high-performance, reliable components grows, brass auto parts will remain essential in driving innovation and efficiency in vehicle design and manufacturing.