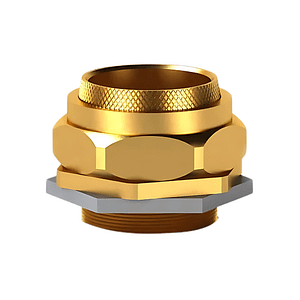

Brass Cable Glands Manufacturer

Brass cable glands are essential components in electrical and instrumentation systems, providing a secure and reliable method for routing and securing cables. These glands create a seal between the cable and the equipment enclosure, protecting against environmental factors such as dust, moisture, and contaminants. Crafted from high-quality brass, these glands offer durability, corrosion resistance, and superior mechanical strength, making them ideal for a wide range of industrial applications.

Robust Construction

Brass cable glands are designed to withstand the rigors of industrial environments. Constructed from solid brass or brass alloys, these glands offer exceptional mechanical strength, ensuring reliable cable management even in demanding conditions. The rugged construction of brass glands provides protection against impacts, vibrations, and abrasion, helping to maintain cable integrity and prevent damage or failure.

Environmental Protection

One of the primary functions of brass cable glands is to provide environmental protection for cables entering equipment enclosures or junction boxes. These glands create a tight seal around the cable, preventing the ingress of moisture, dust, and other contaminants. This protection is essential for maintaining the integrity of electrical and instrumentation systems, particularly in harsh environments such as industrial plants, offshore platforms, and outdoor installations.

Corrosion Resistance

Brass cable glands offer excellent resistance to corrosion, making them suitable for use in both indoor and outdoor applications. Brass is inherently resistant to rust and oxidation, ensuring long-term reliability and performance in corrosive environments. This corrosion resistance helps prolong the service life of cable glands, reducing maintenance requirements and ensuring continued protection for cables and equipment.

Versatility and Adaptability

Brass cable glands are available in a variety of sizes, thread types, and configurations to accommodate different cable diameters and installation requirements. Whether for armoured or unarmoured cables, metric or NPT threads, brass glands can be customized to suit specific application needs. Additionally, brass glands may feature various sealing options, such as neoprene or silicone seals, to provide additional protection against moisture and environmental ingress.

Ease of Installation

Installing brass cable glands is a straightforward process that requires minimal tools and expertise. Most glands feature a simple design with a threaded entry and a compression nut for securing the cable in place. This allows for quick and easy installation without the need for specialized equipment or training. Tightening the compression nut creates a secure and watertight seal around the cable, providing reliable cable management and protection.

Compliance and Certification

Brass cable glands may be certified to various industry standards and regulations, ensuring compliance with safety and performance requirements. Certifications such as IP (Ingress Protection) ratings and ATEX (ATmosphères EXplosibles) certification indicate that the glands meet specific criteria for environmental protection and hazardous area use. Choosing certified brass cable glands provides assurance of quality, reliability, and safety in critical applications.

Conclusion

Brass cable glands are indispensable components in electrical and instrumentation systems, offering secure and reliable cable management solutions for industrial applications. With their robust construction, environmental protection, corrosion resistance, and versatility, brass glands provide peace of mind for engineers, technicians, and facility managers. Whether for indoor or outdoor installations, hazardous or non-hazardous areas, brass cable glands play a vital role in ensuring the integrity and performance of electrical systems in a wide range of industries.