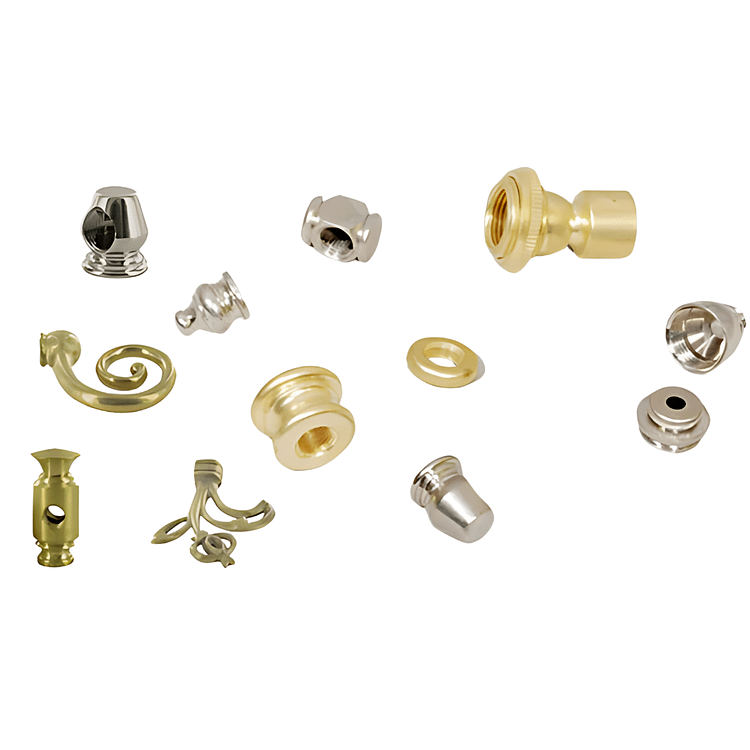

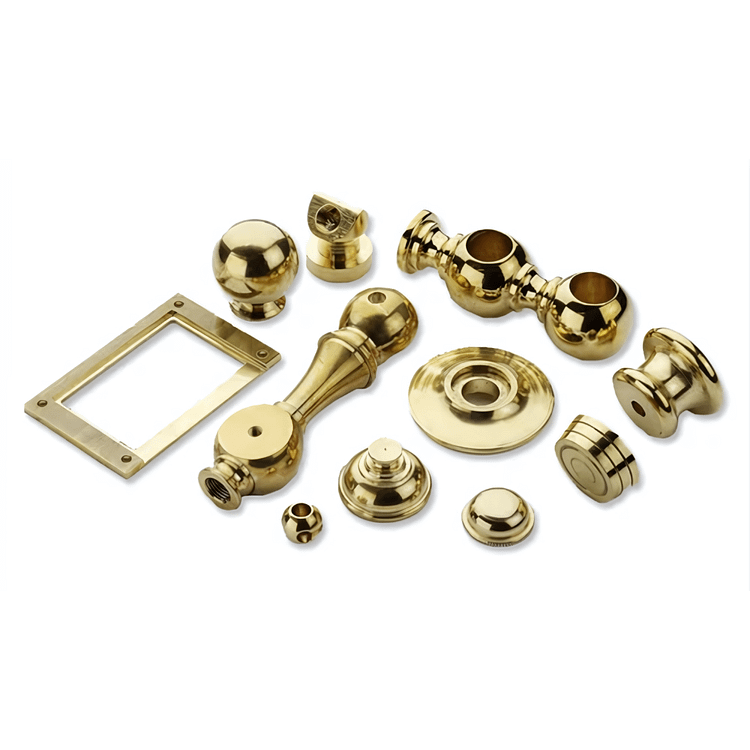

Brass Turned Components for Precision Industrial Applications

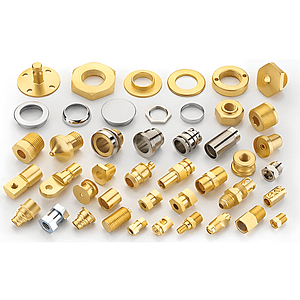

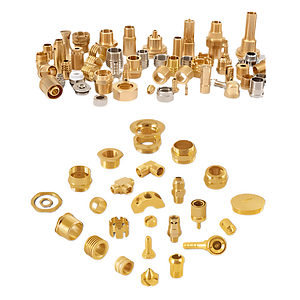

Brass turned components are precision‑machined parts produced on CNC and automatic turning machines for use in automotive, plumbing, electrical, electronics, aerospace and general engineering applications. By combining accurate turning processes with the inherent properties of brass, these components deliver stable dimensions, durability and reliable performance in demanding assemblies worldwide.

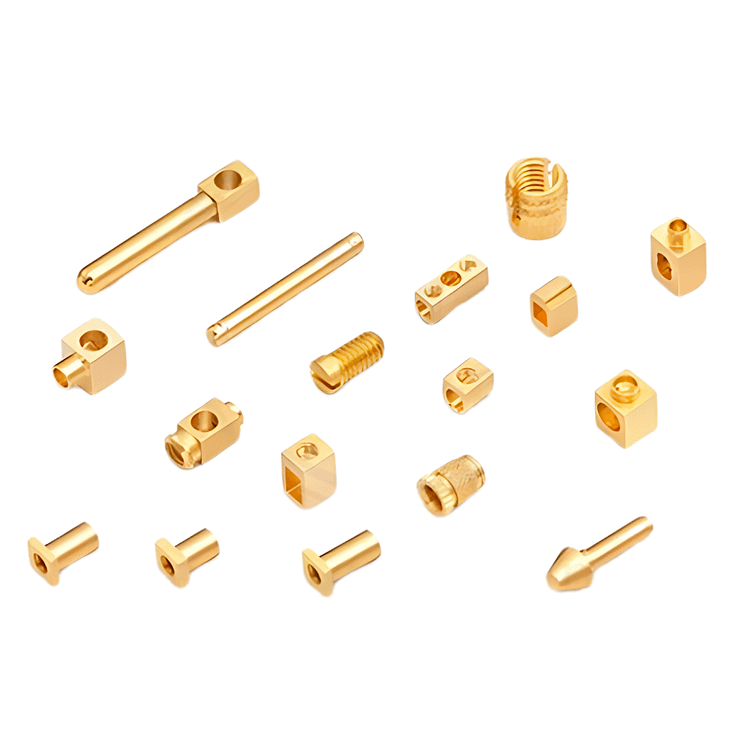

Precision and Dimensional Accuracy

Turning allows brass components to be produced with tight tolerances, clean surfaces and complex external and internal geometries. With modern CNC turning:

- Critical diameters, threads and features are held consistently across large batches

- Complex shapes and multi‑step profiles can be machined in a single setup

- Repeatability is maintained from prototype to full production runs

This precision is vital in sectors such as electronics, medical devices and fluid control, where even small deviations can affect sealing, alignment or functional performance.

Durability, Strength and Corrosion Resistance

Brass, a copper‑zinc alloy, provides an excellent combination of mechanical strength, wear resistance and corrosion resistance. In turned components this means:

- Threads and sealing surfaces stand up to repeated assembly and use

- Parts maintain their integrity under vibration, pressure and thermal cycling

- Components remain reliable in environments exposed to moisture or many common process media

This robustness makes brass turned parts suitable for long‑life applications in automotive, plumbing, instrumentation and industrial systems.

Versatile Applications Across Industries

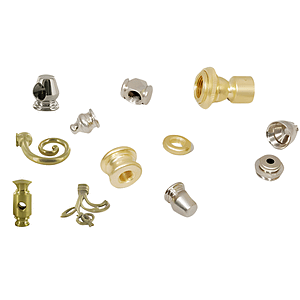

Brass turned components are used wherever compact, accurate and reliable metal parts are needed. Typical application areas include:

- Automotive and transportation: Fuel and fluid connectors, sensor housings, small mechanical linkages and fittings

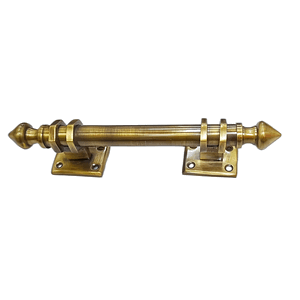

- Plumbing and HVAC: Turned fittings, valve components and connectors for water, gas and heating systems

- Electrical and electronics: Terminals, contact pins, spacers, inserts and precision hardware for connectors and devices

- Aerospace and industrial machinery: Small precision parts in control systems, actuators and instrumentation

This broad applicability allows OEMs and engineers to standardize on brass turned parts for multiple product lines.

Cost‑Effective Manufacturing and Lifecycle

Brass machines efficiently, which reduces cycle times and tooling wear compared with many harder alloys. For buyers this translates into:

- Competitive part costs for both small and large production volumes

- Stable quality with fewer machining defects or rework

- Long‑lasting components that reduce replacement and maintenance frequency

The combination of economical production and long service life makes brass turned components a cost‑effective choice over the full product lifecycle.

Customization and Design Flexibility

The turning process provides extensive flexibility for creating custom parts to exact specifications. Brass turned components can be:

- Produced to customer drawings, CAD models or samples

- Supplied with specific threads, bores, grooves, undercuts and cross‑holes

- Integrated with multiple functions (e.g., sealing, mounting and flow control) in a single part

This design freedom supports optimized assemblies, reduced part count and better performance in specialized applications.

Sustainability and Recycling

Brass is fully recyclable and retains its core properties after recycling, which supports more sustainable manufacturing. Using brass turned components helps:

- Reduce the use of virgin raw materials

- Enable recovery and reuse of machining scrap

- Align products with environmental and ESG objectives without sacrificing performance

Combined with long component lifespan, this makes brass a responsible material choice for precision‑machined parts.

Conclusion

Brass turned components deliver the precision, strength and reliability required in modern automotive, plumbing, electrical, aerospace and industrial systems. With excellent machinability, corrosion resistance, wide application versatility and strong support for customization and sustainability, CNC‑turned brass parts remain a preferred solution for high‑accuracy, high‑performance component needs in global markets.