Brass Hardware Parts: The 2026 Guide to Quality, Trends, and Industrial Applications

In 2026, the global shift toward sustainable and high-durability materials has placed brass hardware parts at the center of both industrial engineering and luxury architecture. Brass is no longer just a “traditional” choice; it is a high-performance alloy essential for everything from EV battery connectors to antimicrobial door hardware.

At Boltorq Brassmet, we specialize in precision-engineered brass components that bridge the gap between aesthetic elegance and industrial-grade strength.

Top 2026 Trends in the Brass Hardware Industry

The demand for brass has surged by over 60% in high-end construction and technical manufacturing. Here is what is driving the market this year:

- Warm Metallic Finishes: Moving away from cold “matte black,” 2026 is the year of Brushed Brass and Champagne Bronze. These finishes offer a muted, sophisticated look that develops a unique patina over time.

- Antimicrobial Infrastructure: Due to its natural copper content, brass is being prioritized for “high-touch” surfaces in public spaces and hospitals to naturally reduce bacterial spread.

- Eco-Conscious Manufacturing: Brass is 100% recyclable. Industry leaders are now focusing on Lead-Free Brass Alloys (like C36000 or DZR) to meet strict environmental and health compliance standards.

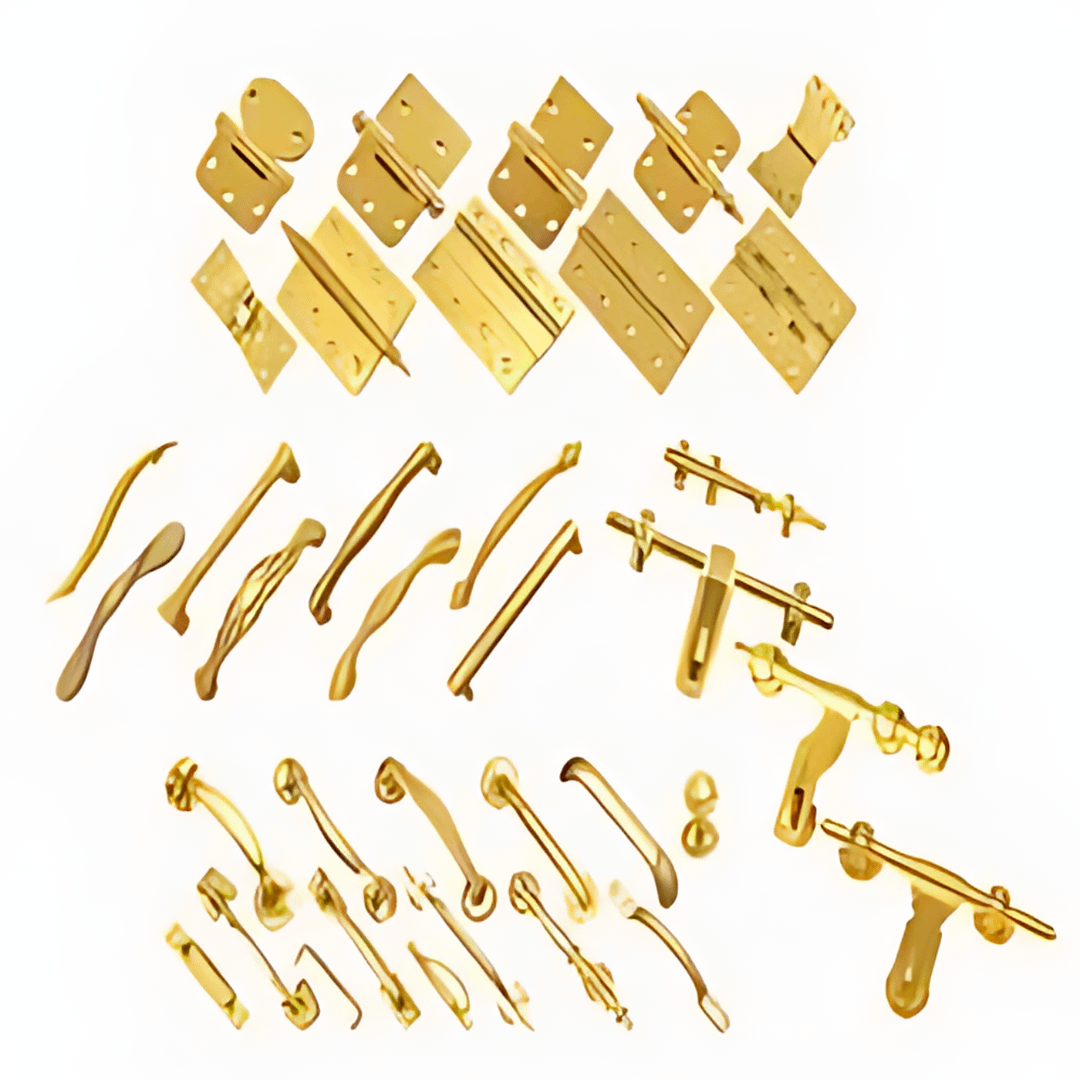

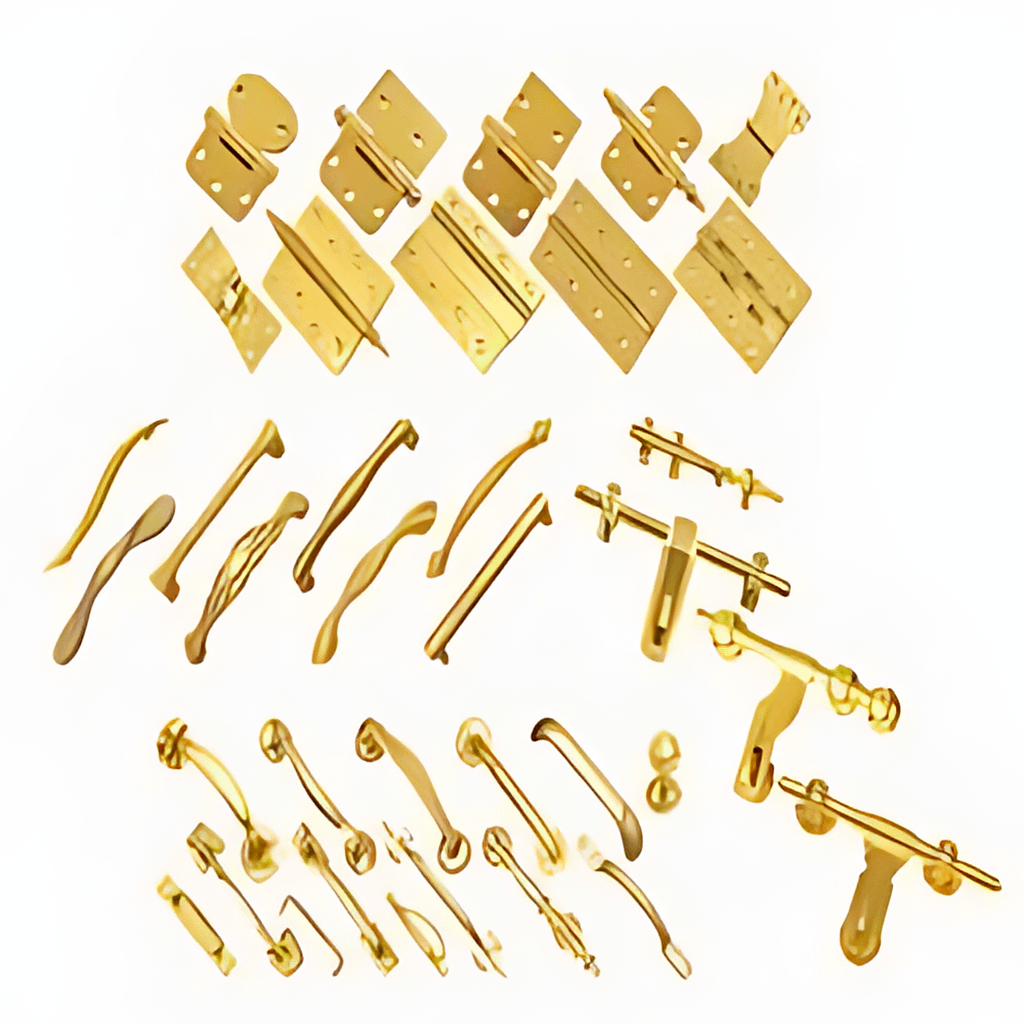

Essential Categories of Brass Hardware Parts

Whether you are sourcing for a commercial build or a precision machine, understanding the categories of hardware is key.

1. Builder & Architectural Hardware

This includes the “visible” components that define a space’s character:

- Door Handles & Levers: Known for their tactile comfort and “heft.”

- Cabinet Pulls & Knobs: Available in polished, antique, or satin finishes.

- Hinges & Pivot Systems: Engineered to support heavy, modern 12-foot vertical spans.

2. Precision Industrial Components

For engineering and manufacturing, brass offers low friction and high conductivity:

- Electrical Connectors & Terminals: Critical for the automotive and telecom sectors.

- Sensor Housings: High-precision M8 to M50 sizes used in industrial IoT.

- Fasteners & Inserts: Brass screws and nuts that provide corrosion resistance where steel fails.

How to Choose High-Quality Brass Hardware

Don’t be fooled by “brass-plated” imitations. Here is the Boltorq Quality Checklist:

| Feature | Solid Brass (Premium) | Brass-Plated (Budget) |

| Weight | Heavy, dense feel. | Significantly lighter. |

| Magnet Test | Non-magnetic. | Often attracts magnets (steel core). |

| Durability | Won’t chip or flake. | Coating can peel in humid areas. |

| Patina | Ages beautifully into a rich bronze. | Turns “rusty” or grey when plating fails. |

Pro Tip: Always request a Material Test Report (MTR). In 2026, reputable manufacturers like Boltorq Brassmet provide traceable certificates ensuring the alloy composition meets ASTM or ISO standards.

Maintenance: Keeping Your Brass Hardware Pristine

To maintain the luster of your hardware without damaging the protective lacquer, follow these 2026 “Green Cleaning” steps:

- Lacquered Brass: Clean only with a soft, damp microfiber cloth. Avoid ammonia-based window cleaners, as they strip the protective coating.

- Unlacquered (Raw) Brass: If you prefer the “golden shine” over the natural “aged patina,” use a mild solution of white vinegar and baking soda to gently restore the brilliance.

- Avoid Abrasives: Never use steel wool or scouring pads; they create micro-scratches that trap grime and accelerate tarnishing.

Why Source from Boltorq Brassmet?

Located in the heart of India’s brass hub, Boltorq Brassmet Industries combines a decade of heritage with AI-integrated precision machining. We provide:

- Customized Solutions: Parts manufactured to your exact blueprints.

- DZR & Lead-Free Options: Future-proofed for health and safety regulations.

- Global Export Quality: Serving infrastructure projects across Europe and the USA.

Ready to elevate your project with premium brass hardware?

Explore our full catalog of decorative and industrial parts at boltorqbrassmet.com or contact our technical team for a custom quote today.

What is the difference between solid brass and brass-plated hardware?

Solid brass is an alloy of copper and zinc throughout the entire piece, offering superior durability and natural corrosion resistance. Brass-plated hardware is typically made of steel or zinc with a thin layer of brass on the surface. While cheaper, plating can flake, rust, or wear off over time. At Boltorq Brassmet, we specialize in solid brass to ensure lifelong performance.

Does brass hardware rust or corrode?

Brass does not “rust” like iron or steel because it contains no iron. However, it can develop a patina (a green or brown surface oxidation) over time when exposed to oxygen and moisture. This patina actually acts as a protective layer. For harsh environments, we recommend DZR (Dezincification Resistant) brass to prevent deep-seated corrosion.

Is brass hardware antimicrobial?

Yes! Brass is a copper-based alloy, and copper has natural oligodynamic properties that kill bacteria, viruses, and fungi within hours of contact. This makes brass hardware parts like door handles and cabinet pulls an excellent choice for hospitals, schools, and high-traffic commercial buildings.

Can you manufacture custom brass parts based on specific drawings?

Absolutely. Boltorq Brassmet is a leading manufacturer in Jamnagar equipped with advanced CNC and VMC machinery. We can produce custom brass hardware parts ranging from complex electrical connectors to bespoke architectural fittings based on your 2D/3D CAD designs and material specifications.

Why is brass preferred for electrical hardware parts?

Brass is an excellent conductor of electricity, though slightly less than pure copper. However, it is much stronger and more resistant to mechanical wear than copper. This makes it the ideal material for terminals, pins, and connectors that need to maintain a secure physical connection while conducting power.

How do I identify high-quality brass hardware?

You can identify quality through three tests:

- The Scratch Test: A small scratch in an inconspicuous area should reveal a consistent golden yellow color throughout.

- The Weight Test: Solid brass is significantly heavier than aluminum or zinc alloys.

- The Magnet Test: Pure brass is non-magnetic. If a magnet sticks, it is likely brass-plated steel.

0 Comments