What Really Makes Up Brass? (Composition, Elements & Endless Uses Explained!)

You see it everywhere – from a gleaming trumpet serenading a crowd to a sturdy doorknob welcoming you home – but what is brass, really? It possesses a certain allure, a warm, inviting glow. But beneath that pleasing aesthetic lies a complex story of alchemy and industry. Brass isn’t some singular, elemental entity plucked from the earth; it’s a carefully constructed alloy, a fantastic melange of metals with a secret recipe. We’re about to embark on a journey deep into its core ingredients, exploring the alchemical dance that gives brass its remarkable properties, and understanding why it’s been a human favorite for millennia. Prepare to uncover everything from its ancient, almost accidental origins to modern controversies, ethical dilemmas, and its surprisingly high-tech future.

Brass, at its heart, is primarily an alloy of copper and zinc. This seemingly simple combination unlocks a world of possibilities.

Copper and Zinc – The Heart of Brass

At its core, brass is a clever and surprisingly nuanced mix of copper and zinc. Think of them as the Batman and Robin of the metal world – copper providing the strength and corrosion resistance, zinc modulating the color and ductility.

However, unlike a fixed comic book dynamic, the “Secret Sauce” of brass lies in its variable ratios. It’s not a fixed recipe etched in stone! Different proportions of copper (typically ranging from 55% to a generous 95%) and zinc (making up the remaining 5% to 40%) create vastly different types of brass. An alloy boasting 85% copper and 15% zinc will behave in markedly different ways, possessing unique characteristics, compared to its sibling composed of 60% copper and 40% zinc. Why this dramatic variance? Because these carefully calibrated ratios directly and profoundly impact fundamental properties like color, tensile strength, malleability, and even resistance to corrosion. The higher the zinc content, for example, the more golden and less reddish the brass becomes, and the greater its strength.

So, what is the chemical composition of brass? It’s a copper-zinc alloy, with the ratio of these elements determining its specific properties. Zinc content profoundly affects these properties. Higher zinc often leads to increased strength and a change in color.

The Supporting Cast: Minor Elements That Make a Major Difference

While copper and zinc form the foundation, the story of brass doesn’t end there. Sometimes, a few carefully chosen extra ingredients are added, a dash of this, a pinch of that, to supercharge the brass, tailoring its capabilities for highly specific tasks. These minor elements act like specialized spices in a chef’s repertoire, transforming a simple dish into a culinary masterpiece.

Take Lead, for example. Historically, it was added to create what’s known as free-machining brass. Think of it as adding butter to dough – it makes the brass easier to cut, shape, and generally work with, lending itself beautifully to intricate designs and precision engineering. Free machining brass like C360 often contains around 2.5-3.7% lead. But wait… there’s a catch, a twist in our tale that we’ll unravel later.

Then there’s Tin, the sea dog’s friend. A touch of tin significantly boosts corrosion resistance, especially against the relentless assault of saltwater. This makes it an invaluable ally in marine applications, ensuring that fittings and fixtures can withstand the harsh ocean environment. Naval brass, for instance, typically incorporates around 1% tin to enhance its durability in maritime settings.

And let’s not forget Aluminum, the protector. Aluminum forms a thin, almost invisible, oxide layer on the surface of the brass, providing even better corrosion resistance than copper or zinc alone can offer. It’s like a microscopic suit of armor, defending against the elements while simultaneously adding a measure of strength to the overall alloy.

Beyond these headliners, a host of other notable elements can contribute their unique talents: arsenic for enhanced dezincification resistance (preventing the zinc from leaching out in certain environments), iron, phosphorus, manganese, silicon, and nickel for added strength and other specialized properties. Each element plays a specific role, a carefully orchestrated performance that results in a material greater than the sum of its parts.

Which elements are added to brass for specific properties? Lead for machinability, tin for corrosion resistance in marine environments, and aluminum for overall corrosion resistance and strength.

A Blast from the Past: The Ancient History of Brass

The story of brass is not just a tale of chemistry and engineering; it’s a journey through human history itself. Brass wasn’t “invented” overnight by some lone metallurgist in a lab coat! Its early forms were often stumbled upon quite accidentally, a happy consequence of heating copper with zinc-rich ores. Imagine early metallurgists experimenting with different combinations, not fully understanding the processes at play, yet unlocking a material with remarkable potential.

Early evidence of brass production stretches back to the 3rd millennium BCE in the Middle East and Mediterranean regions. The Greeks, with their penchant for naming things, knew it as “oreichalcos,” a term shrouded in both history and myth. The Romans, ever the pragmatic engineers, embraced brass wholeheartedly, calling it “orichalcum” and deploying it extensively for coins, decorative objects, and even military gear from the 3rd century BCE onwards. Brass became an integral part of Roman civilization, a testament to its versatility and enduring appeal.

But how did these ancient civilizations manage to create brass without the benefit of modern metallurgy? The answer lies in a process known as the “Calamine Process,” a testament to the ingenuity of our ancestors. This involved heating copper with zinc ore (calamine, hence the name) and charcoal in a crucible. As the mixture heated, the zinc in the ore would vaporize and infuse itself into the solid copper. Think of it as a form of metallic impregnation, a slow and painstaking process that required both skill and patience. This method remained the dominant technique for brass production in Europe all the way up to the 18th century.

Why this roundabout approach? Because extracting pure metallic zinc was remarkably tricky due to its relatively low boiling point. The zinc would simply vaporize before it could be collected in a liquid form. Other civilizations, however, charted a different course. China, as early as the 10th century AD, and India developed techniques for producing metallic zinc earlier than their European counterparts.

The Industrial Revolution, with its advancements in mining and metallurgy, finally unlocked the secrets of efficient zinc extraction. This, in turn, revolutionized brass production, ushering in an era of mass manufacturing and widespread availability.

Brass in the Modern World: Where Does It Shine Today?

Brass’s enduring legacy stems from its remarkable versatility. Its unique combination of properties—strength, corrosion resistance, malleability, and aesthetic appeal—means it’s found virtually everywhere in the modern world, often playing a silent, unassuming role.

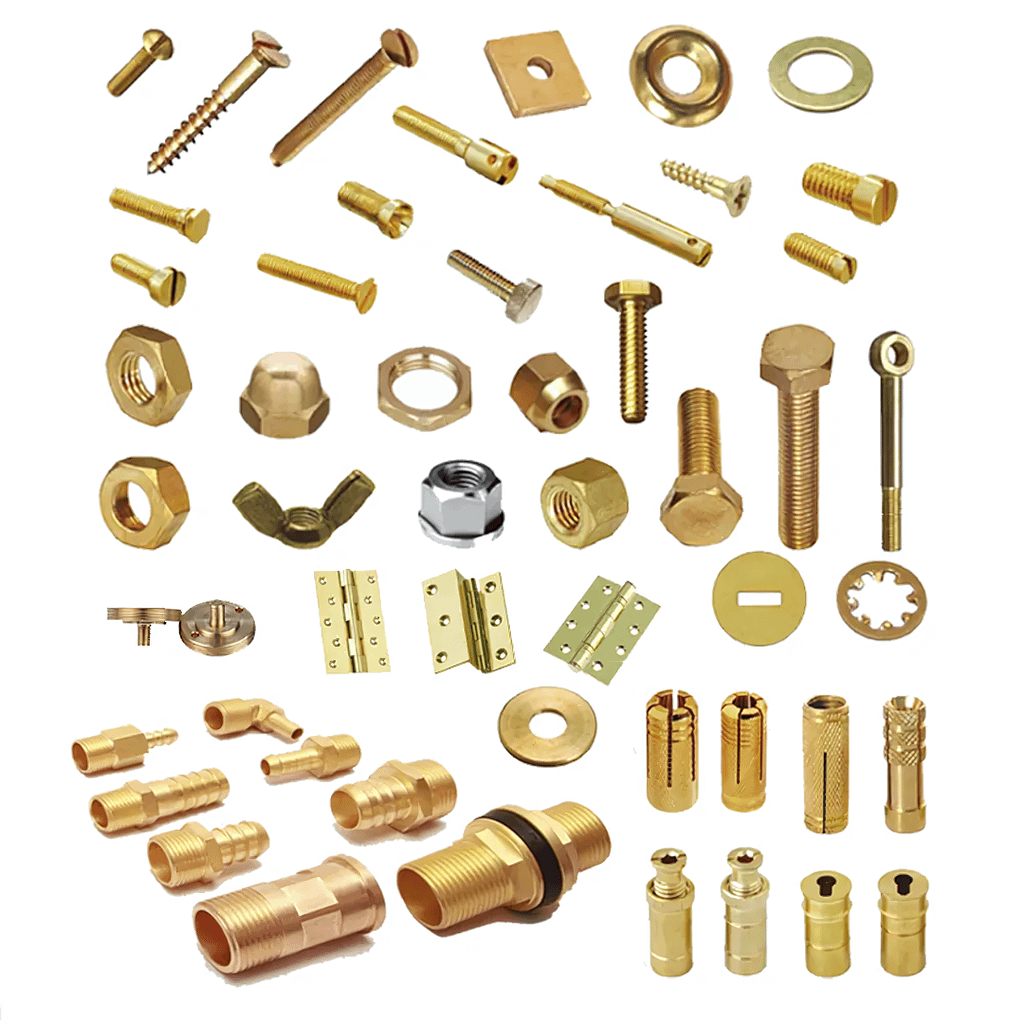

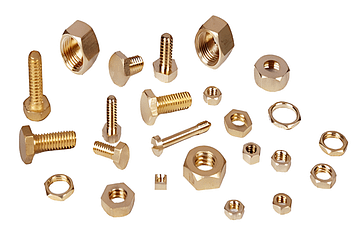

Consider Plumbing. Unseen yet indispensable, brass forms the backbone of our water systems. Valves, faucets, pipe fittings—all rely on brass for its durability, corrosion resistance, and machinability. It’s also a key component in radiators and heat exchangers, efficiently transferring heat while resisting the corrosive effects of water. And let’s not forget dielectric couplings, where brass prevents galvanic corrosion between dissimilar metals, ensuring the longevity of our plumbing systems.

Then there are Musical Instruments. From the soaring notes of a trumpet to the mellow tones of a trombone, brass brings music to our ears. Its acoustic properties, malleability (allowing it to be shaped into complex forms), and durability make it the ideal material for creating instruments that produce rich, resonant sounds.

Out on the open water, Marine Hardware depends on brass to battle the brine. Fittings, fixtures, fasteners, propellers, and nautical instruments all rely on brass’s ability to withstand the corrosive effects of saltwater. Naval brass, with its addition of tin and sometimes arsenic, excels in this demanding environment.

Even in the realm of Electronics, brass plays a crucial role. Connectors, terminals, switches, sockets, wiring parts, and battery components all utilize brass for its excellent electrical conductivity. It also finds application in heat sinks, efficiently dissipating heat from sensitive electronic components, as well as in grounding systems, transformers, and antennae.

What are common uses of brass? Plumbing components, musical instruments, marine hardware, and electrical connectors are just a few examples of brass’s widespread applications.

The Lead Problem: A Bitter Pill in Brass’s History

The story of brass, like many tales of human innovation, isn’t without its darker chapters. The inclusion of lead in brass, while initially seen as a technological boon, has cast a long shadow over its history.

Why was lead added in the first place? Quite simply, it dramatically improved machinability, making the brass easier to cut, shape, and form. However, the bitter truth is that lead is a potent toxin, with no safe level of exposure.

The primary concern revolves around Leaching. Lead can leach from brass plumbing, especially older fixtures, contaminating our drinking water. This poses a significant health risk, particularly for children, whose developing brains are especially vulnerable to lead’s damaging effects. Furthermore, FDA investigations have revealed lead leaching from certain brass and aluminum cookware into food. Yikes!

It’s crucial to understand that even the term “Lead-Free” doesn’t guarantee the complete absence of lead. Current U.S. standards allow for up to 0.25% lead in wetted surfaces for plumbing. The uncomfortable reality is that even brand-new “lead-free” faucets can leach lead into the water during the first few weeks of use. This raises a critical question: are our current standards truly adequate to protect public health?

The Health Impacts of lead exposure are devastating. In children, it can impair brain development, lower IQ, and cause behavioral problems. In adults, it can contribute to heart problems, kidney damage, reproductive issues, and neurological changes.

In response to these concerns, a wave of Regulatory Pushback has emerged. The U.S. Safe Drinking Water Act (SDWA) defines “lead-free” and mandates certification through organizations like NSF/ANSI 372. California’s Prop 65 requires warnings for even trace amounts of lead, even those below the “lead-free” threshold. In January 2023, California implemented a new ban on faucets that leach more than 1 microgram of lead. Globally, efforts are underway to develop truly lead-free alloys.

Is brass safe to use? The presence of lead in some brass alloys poses a health risk, particularly in plumbing applications. However, regulations are tightening, and the industry is moving towards lead-free alternatives.

The Brass Renaissance: Innovations & Future-Proofing the Alloy

Despite the challenges posed by lead contamination, the story of brass is far from over. In fact, a “Brass Renaissance” is underway, driven by a commitment to sustainability, innovation, and responsible manufacturing.

The Green Shift towards sustainable manufacturing is transforming the industry. The use of recycled brass scrap is becoming increasingly common, with many alloys boasting 90%+ recycled content. This drastically reduces energy consumption and CO2 emissions compared to using virgin metals. The development of lead-free alloys is accelerating, paving the way for safer plumbing and consumer products. Energy-efficient technologies like induction furnaces and AI-driven optimization are further reducing the environmental footprint of brass production. And waste reduction strategies, such as precision casting, CNC machining, and closed-loop systems, are minimizing material waste and maximizing resource utilization.

Recycling is at the heart of this transformation. Brass is infinitely recyclable without losing its desirable properties, making it a true circular economy champion. Future technologies like AI-powered sorting, laser separation, and “urban mining” from electronic waste promise to further enhance recycling efforts and unlock new sources of valuable materials.

The Antimicrobial Advantage of brass is also gaining recognition. Copper, and by extension brass, naturally kills bacteria and viruses on contact. This inherent antimicrobial property is being harnessed in healthcare settings, where brass is being used for high-touch surfaces in hospitals to reduce the spread of infections. Future research is focused on enhancing the efficacy and durability of this antimicrobial effect, as well as expanding its application to a wider range of surfaces.

Finally, the industry is continually experimenting with New Alloy Combinations, optimizing properties for emerging industries and applications.

Conclusion: Brass – An Enduring Legacy, A Brilliant Future

From its accidental discovery in antiquity to its critical role in modern technology, brass has traversed an incredible journey through human history.

Its unique composition, a carefully balanced blend of copper, zinc, and strategically chosen minor elements, bestows upon it a remarkable combination of properties, making it suitable for a vast array of applications. However, past practices, particularly the inclusion of lead, have prompted critical reevaluation and spurred vital innovations.

Looking ahead, brass is poised for continued success. With the advent of lead-free alloys, the adoption of sustainable manufacturing practices, and the exploitation of its inherent antimicrobial potential, brass is evolving to meet the demands of a rapidly changing world. It is not merely a metal of the past, but a material of the future.

Your Next Brass Adventure

Thinking about using brass in your next project? Be sure to look for lead-free certifications to ensure the safety of your application. Explore further the fascinating world of brass!

0 Comments