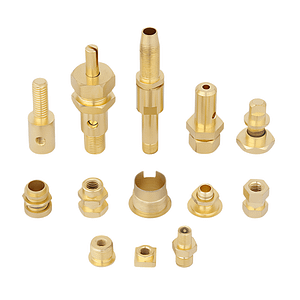

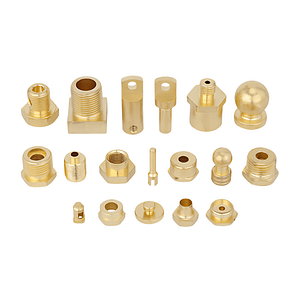

Customized Brass Parts for Precision Applications

Customized brass parts are engineered to meet exact design requirements across automotive, electrical, plumbing, aerospace, medical and architectural applications. Using brass’s excellent machinability, corrosion resistance and strength, manufacturers produce components from customer drawings, CAD models or prototypes—delivering fit, function and performance optimized for specific use cases.

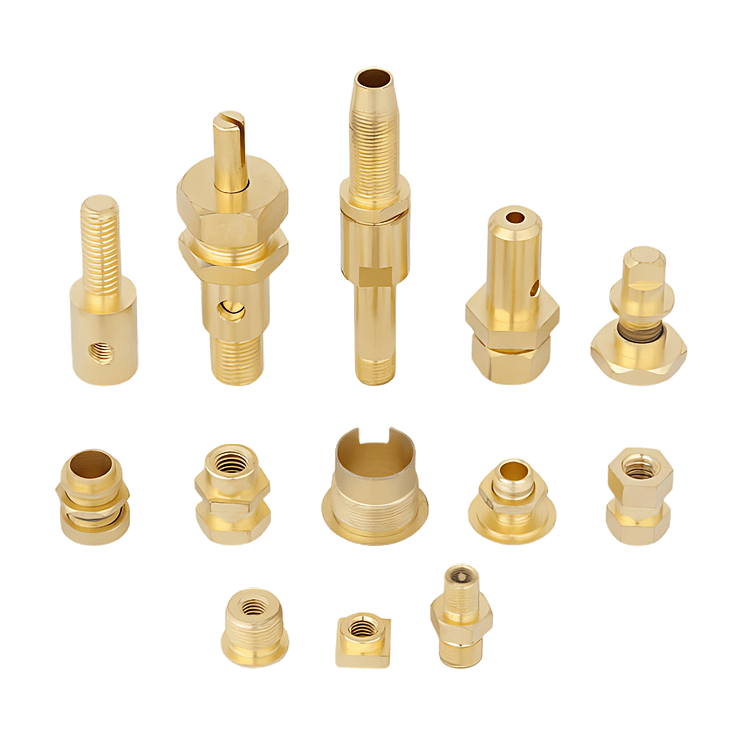

Versatility in Design and Shapes

Brass’s formability supports unlimited design freedom for custom components:

- Complex geometries with undercuts, cross‑holes and multi‑step profiles

- Standard and non‑standard threads, splines and bearing surfaces

- Thin‑walled structures, knurling and decorative surface patterns

- Hybrid parts combining multiple functions in single components

Whether simple brackets or intricate valve bodies, brass handles both functional and aesthetic customization.

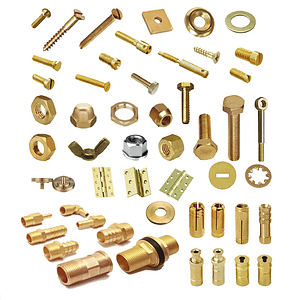

Brass Material Advantages for Custom Parts

Brass combines properties ideal for precision custom manufacturing:

- Outstanding machinability: Clean cuts, minimal tool wear, fast cycle times

- Corrosion resistance: Reliable performance in moisture, salt and chemical exposure

- Strength and wear resistance: Suitable for loaded, dynamic and sealing applications

- Thermal/electrical conductivity: Perfect for heat sinks, contacts and connectors

- Aesthetic golden finish: Premium appearance for visible hardware

These characteristics make brass suitable for both harsh industrial environments and decorative applications.

Tailored Performance Through Alloy Selection

Different brass alloys can be specified to optimize specific performance needs:

- Lead-free brass: Plumbing, potable water, food contact applications

- High‑strength brass: Automotive, aerospace, heavy mechanical loads

- Naval brass: Marine, coastal, high corrosion environments

- Free‑machining brass: Complex geometries, high‑volume production

Surface treatments like nickel plating, passivation or clear coating further enhance corrosion resistance and appearance.

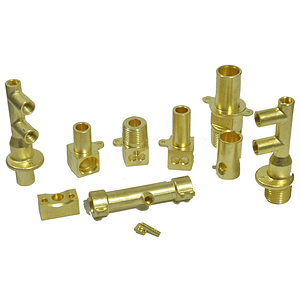

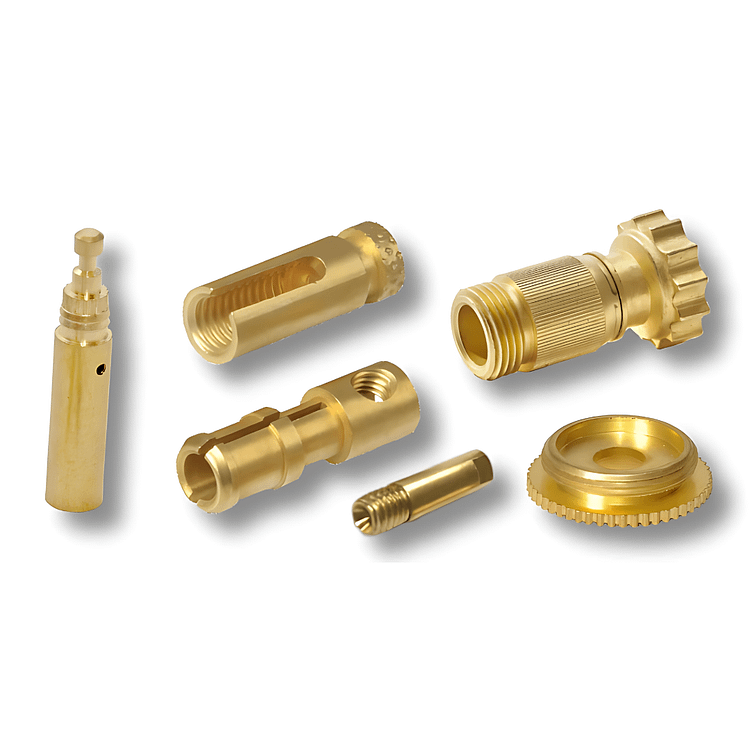

Precision Manufacturing Processes

Custom brass parts leverage multiple complementary manufacturing methods:

- CNC turning/milling: High accuracy (±0.01mm), complex 3D contours

- Automatic screw machining: High‑volume, tight‑tolerance cylindrical parts

- Casting/forging: Near‑net shapes for complex, high‑stress components

- Secondary operations: Drilling, tapping, grinding, plating, assembly

Quality control includes dimensional inspection, material certification and functional testing to customer specifications.

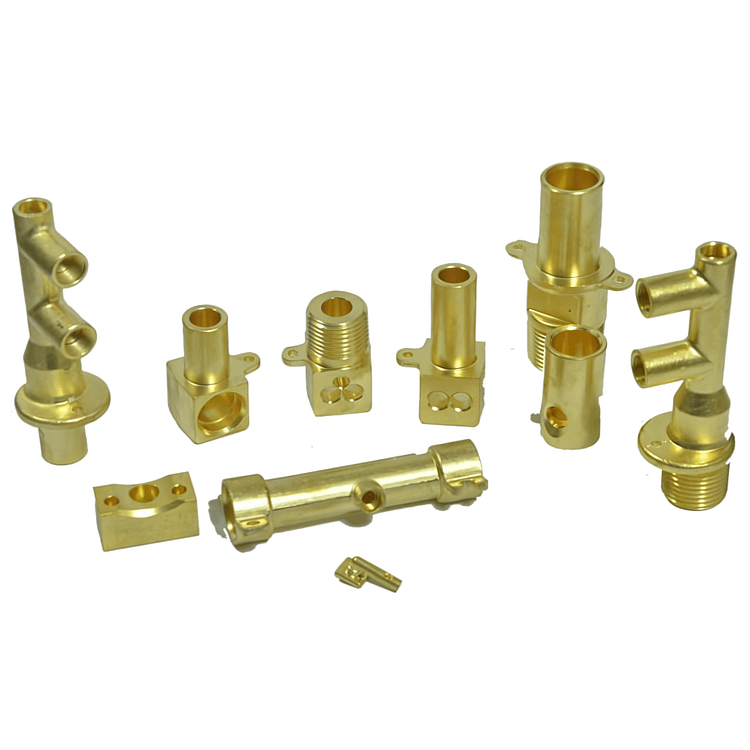

Wide Range of Applications

Customized brass parts find applications across various industries, including automotive, aerospace, electronics, plumbing, architecture, and more. From intricate components in precision instruments to robust fittings in heavy machinery, brass parts offer versatility and reliability in diverse environments.

Engineering Collaboration and Support

The custom brass manufacturing process typically includes:

- Design consultation: Optimizing manufacturability and performance

- Prototyping: Rapid samples for fit and function validation

- Material selection: Matching alloy to application requirements

- Tooling and process development: Production setup for consistent quality

- Production and delivery: Scalable manufacturing with reliable lead times

Close collaboration ensures parts meet technical specifications, budget and schedule requirements.

Cost‑Effective Custom Solutions

Custom brass parts balance performance and economics:

- Efficient machining reduces per‑part costs at moderate volumes

- Long service life minimizes replacement and maintenance

- Material properties reduce assembly failures and warranty claims

- Design optimization eliminates expensive secondary operations

Superior lifecycle performance often offsets initial customization costs.

Conclusion

Customized brass parts provide unmatched design flexibility, precision manufacturing and material performance for applications where standard parts fall short. From complex automotive connectors to architectural hardware, brass’s machinability, strength, corrosion resistance and aesthetic appeal support tailored engineering solutions across industries worldwide.