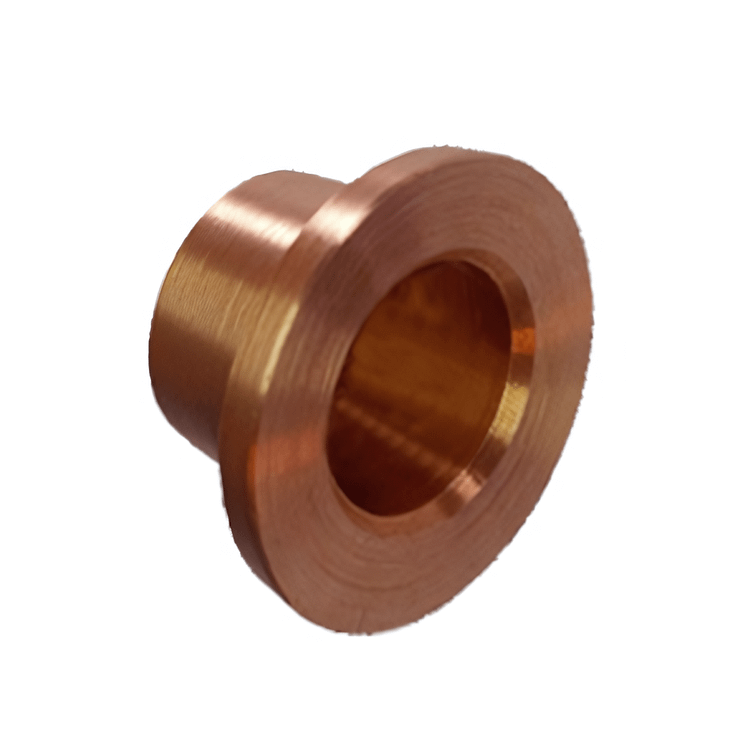

Bronze Alloys Casting for Durable Industrial Components

Bronze alloys casting creates strong, corrosion‑resistant metal parts by pouring molten bronze into molds, producing components for industrial machinery, marine hardware, valves, bearings and architectural applications. These castings combine traditional craftsmanship with modern alloy engineering for reliable performance in demanding environments.

Bronze Alloy Composition

Bronze alloys are primarily copper and tin (typically 88/12 ratio), with additions like aluminum, silicon, manganese or phosphorus to enhance specific properties:

- Tin bronze: High strength, wear resistance for bearings and gears

- Aluminum bronze: Superior strength, corrosion resistance for marine and aerospace

- Silicon bronze: Weldability, toughness for structural castings

- Leaded bronze: Improved machinability for precision parts

Alloy selection matches the mechanical, corrosion and machinability needs of each application.

Versatile Industrial Applications

Bronze castings serve where strength, corrosion resistance and durability are critical:

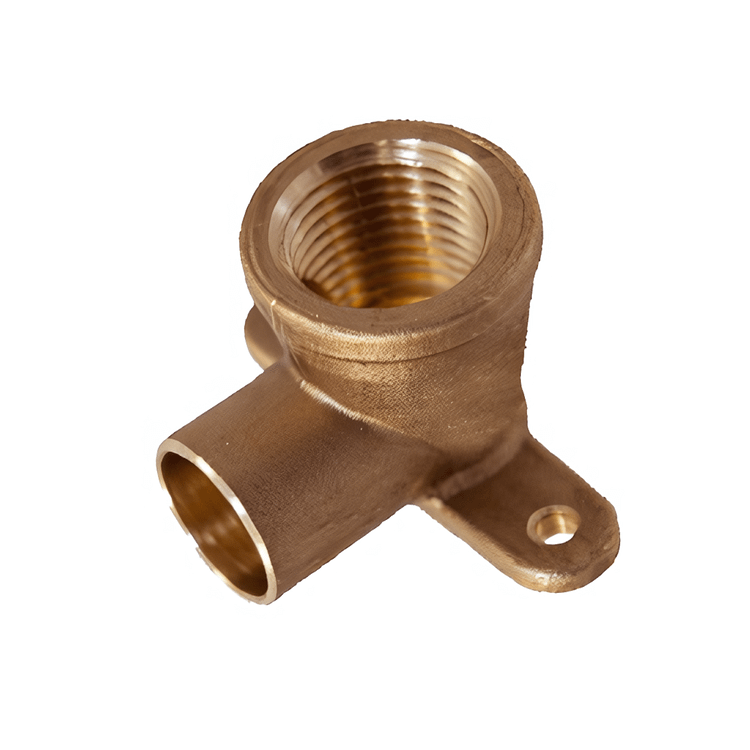

- Marine and offshore: Propellers, pump impellers, valve bodies, fittings

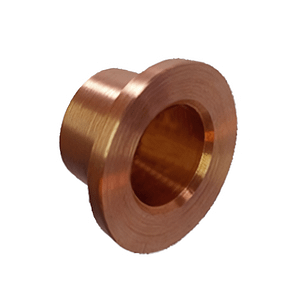

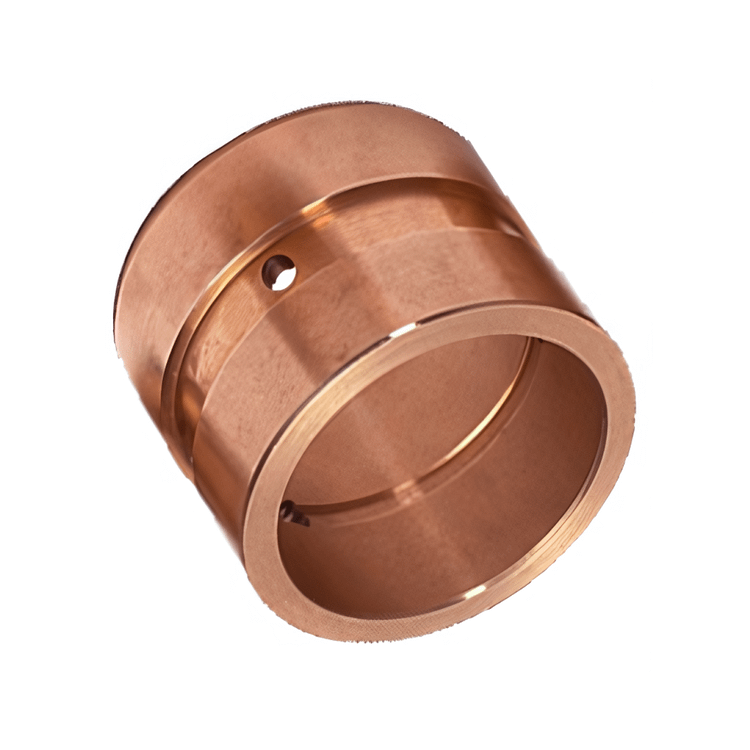

- Industrial machinery: Bearings, bushings, gears, wear plates

- Valves and fittings: Bodies, bonnets, seats for water, oil and gas service

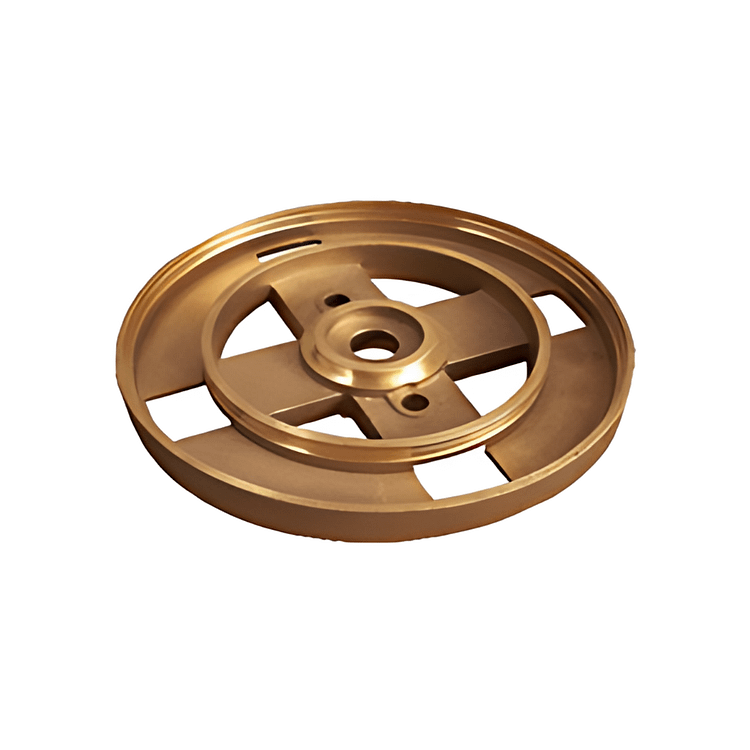

- Architectural and artistic: Door hardware, sculptures, decorative elements

Cast bronze parts excel in both high‑load mechanical roles and decorative applications requiring long‑term outdoor exposure.

Intricate Detailing and Complex Geometries

The casting process captures fine details, undercuts and internal passages that machining alone cannot achieve efficiently:

- Thin walls, ribs and intricate cores

- Multi‑port valve bodies and manifolds

- Artistic patterns and surface textures

- Near‑net shapes that minimize finishing

Lost wax (investment) and sand casting both support high design freedom for complex bronze parts.

Superior Durability and Corrosion Resistance

Cast bronze components withstand harsh conditions better than many ferrous metals:

- Excellent resistance to seawater, industrial fluids and atmospheric corrosion

- High fatigue strength for dynamic loads and vibration

- Natural wear resistance in sliding contact applications

- Stable performance across wide temperature ranges

This longevity reduces maintenance and replacement costs in marine, industrial and infrastructure projects.

Customization and Bespoke Production

Bronze casting supports fully custom components tailored to engineering requirements:

- Pattern/mold design based on customer drawings or 3D models

- Alloy selection for specific mechanical, thermal or corrosion needs

- Controlled casting processes for consistent quality

- Secondary machining, finishing and testing to final specifications

This flexibility serves both prototype development and production quantities.

Eco‑Friendly and Recyclable Material

Bronze is one of the most recyclable engineering metals, retaining full properties after remelting:

- High scrap recovery rates from manufacturing and service

- Reduced need for virgin copper and tin

- Long component life minimizes material turnover and waste

Sustainable sourcing and recycling make bronze casting environmentally responsible.

Conclusion

Bronze alloys casting produces durable, corrosion‑resistant components with excellent mechanical properties and design flexibility for marine, industrial, valve and architectural applications. Combining time‑tested casting techniques with modern alloy engineering, bronze castings deliver long‑life performance where strength and reliability matter most.