Brass Construction Parts

Brass construction parts are precision-engineered copper-zinc alloy components used in residential, commercial, and industrial building projects worldwide. These architectural brass components include fasteners, fittings, connectors, hardware, railings, and decorative elements that provide structural integrity and aesthetic excellence across construction applications.

Contractors, architects, builders, and property developers choose brass building materials for their superior durability, natural corrosion resistance, and distinctive golden appearance in both functional and decorative installations.

Durability and Strength

Brass construction components deliver high tensile strength (300-600 MPa) and mechanical durability, making them ideal for structural fasteners, connectors, pipe fittings, and load-bearing hardware. The robust nature of brass architectural parts withstands heavy loads, vibration, and harsh environmental conditions without compromising structural integrity over decades of service life.

Corrosion Resistance

Unlike steel construction materials, brass parts offer exceptional resistance to rust, oxidation, and atmospheric corrosion. This natural corrosion protection makes brass construction hardware suitable for outdoor applications, coastal buildings, marine environments, and moisture-exposed installations. Brass components maintain performance and appearance for 30-50+ years, reducing maintenance costs and replacement frequency.

Aesthetic Appeal

The distinctive golden-yellow appearance of polished brass construction parts adds elegance, sophistication, and timeless beauty to architectural elements. Brass railings, door hardware, decorative trim, cabinet fixtures, and building accents enhance visual appeal while providing functional performance. Brass finishes complement both traditional and contemporary architectural styles across residential and commercial construction projects.

Versatility in Applications

Brass building components serve diverse applications in construction including:

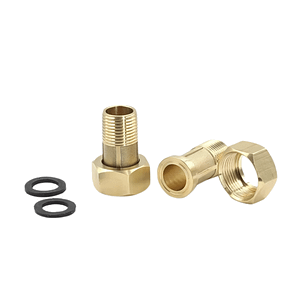

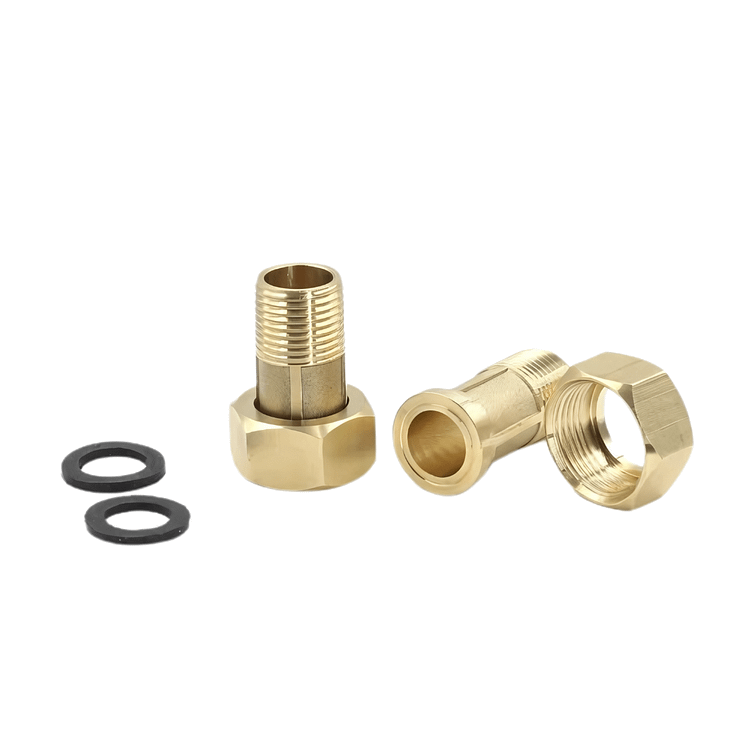

- Plumbing Systems: Pipe fittings, valves, connectors, compression fittings, water supply components

- HVAC Applications: Ductwork fittings, refrigeration connections, heating system hardware

- Electrical Installations: Grounding components, panel hardware, conduit fittings, electrical boxes

- Interior Finishes: Door hardware, cabinet pulls, handrails, decorative trim, lighting fixtures

- Exterior Facades: Cladding fasteners, curtain wall components, window hardware, architectural detailing

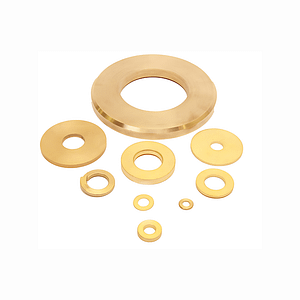

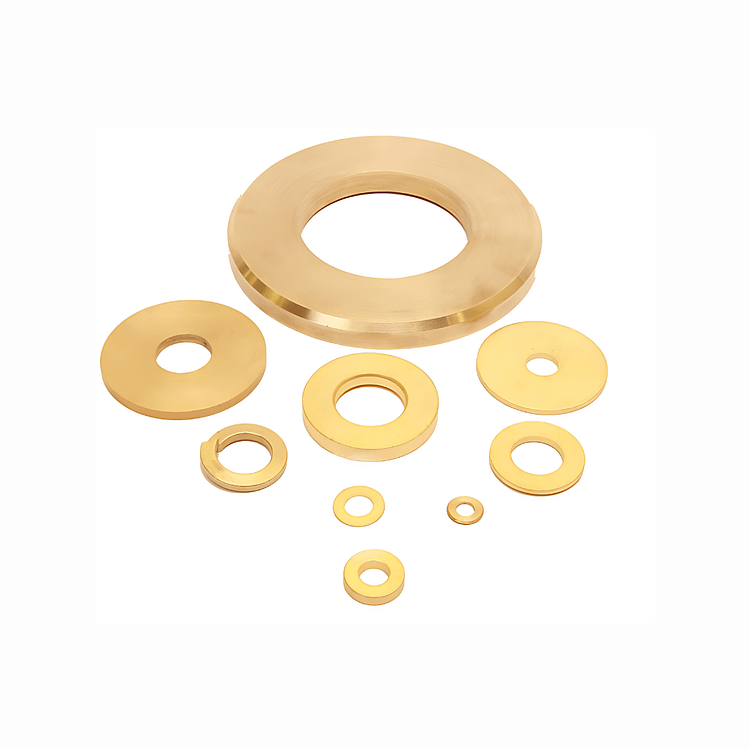

- Structural Connections: Bolts, anchors, brackets, fastening systems for wood, concrete, steel, masonry

This versatility makes brass construction materials indispensable for residential homes, commercial buildings, industrial facilities, and infrastructure projects.

Thermal Conductivity

Brass construction parts exhibit superior thermal conductivity (120 W/m·K), beneficial in temperature-critical construction applications. Brass components efficiently dissipate heat in HVAC systems, electrical installations, and building envelope applications, contributing to energy efficiency, thermal comfort, and stable performance across temperature fluctuations from -40°C to +200°C.

Easy Machinability

Brass alloys offer exceptional machinability (rated 100% baseline per UNS C36000), enabling precise fabrication of construction parts with intricate designs, tight dimensional tolerances (±0.01-0.05mm), and complex geometries. Manufacturers easily produce customized brass building components tailored to specific architectural specifications, project requirements, and design details. This machinability allows cost-effective production of standard and specialty brass construction hardware.

Environmental Sustainability

Brass is 100% infinitely recyclable without property degradation, supporting sustainable construction practices and LEED certification requirements. Using recycled brass construction components reduces virgin material demand by 40-60%, lowers embodied carbon footprint, and minimizes environmental impact. The exceptional durability and 50+ year service life of brass parts reduces construction waste, replacement frequency, and lifecycle costs, contributing to sustainable building goals and circular economy principles.

Conclusion

Brass construction parts provide an optimal combination of durability, corrosion resistance, aesthetic appeal, versatility, and sustainability for modern building applications. Their use in residential, commercial, industrial, and infrastructure projects enhances both structural integrity and architectural beauty, making brass components indispensable in contemporary construction practices.

By incorporating brass building materials into construction designs, architects, engineers, contractors, and builders create functional, durable, and aesthetically superior structures that deliver decades of reliable performance while supporting sustainable building goals and environmental responsibility.