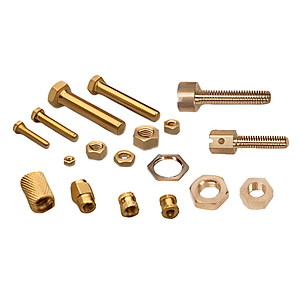

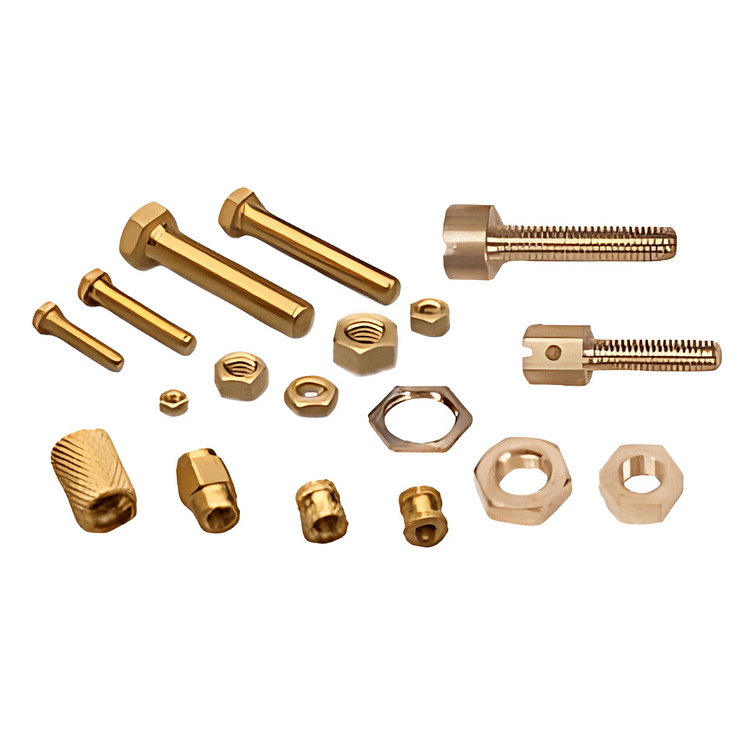

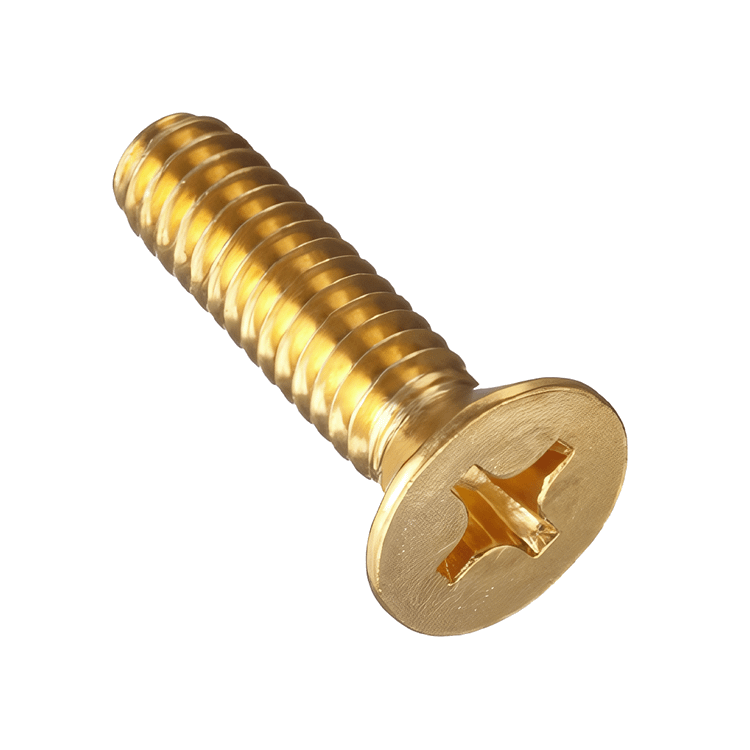

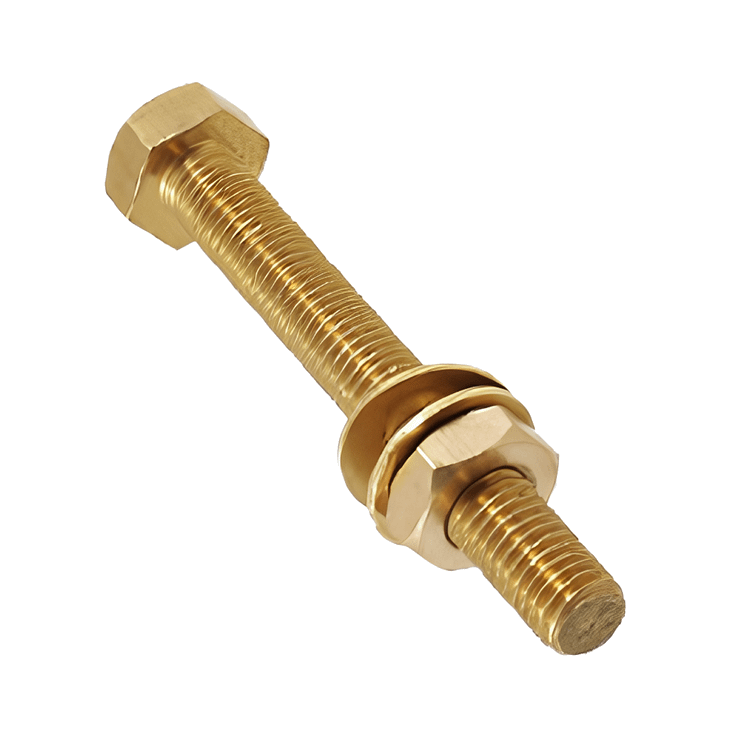

Brass Screws and Brass Bolts for Durable , Corrosion‑Resistant Fastening

Brass screws and brass bolts are essential fastening solutions used in woodworking, electrical, marine, plumbing and industrial applications where strength, corrosion resistance and appearance all matter. Made from a copper‑zinc alloy, these fasteners provide reliable performance in both indoor and outdoor environments, supporting secure, long‑lasting assemblies in global markets.

Durability and Mechanical Strength

Brass screws and bolts offer a strong combination of tensile strength and toughness, making them suitable for both structural and decorative fastening tasks. Properly selected brass fasteners:

- Resist deformation and thread damage during tightening and service

- Maintain clamping force over time, even under vibration and load

- Reduce the need for frequent replacement, improving product longevity

This durability makes brass fasteners a dependable choice for cabinetry, machinery, equipment and architectural elements.

Corrosion Resistance for Harsh and Outdoor Conditions

Unlike many carbon steel fasteners, brass does not rust when exposed to moisture and many common chemicals. This natural corrosion resistance is ideal for:

- Outdoor fixtures and coastal or high‑humidity environments

- Marine hardware and boat fittings

- Plumbing, heating and process systems with water or mild chemicals

Using brass screws and bolts helps keep joints secure and functional even in demanding conditions, lowering maintenance requirements over time.

Electrical Conductivity and Non‑Magnetic Behavior

Brass combines mechanical strength with good electrical conductivity, making brass screws and bolts well suited to electrical and electronic applications. Typical uses include:

- Electrical panels, switchgear and control boxes

- Terminals, connectors and grounding points

- Sensitive devices where non‑magnetic fasteners are preferred

In these roles, brass fasteners support stable, low‑resistance connections and help avoid magnetic interference in delicate equipment.

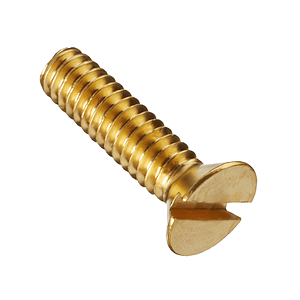

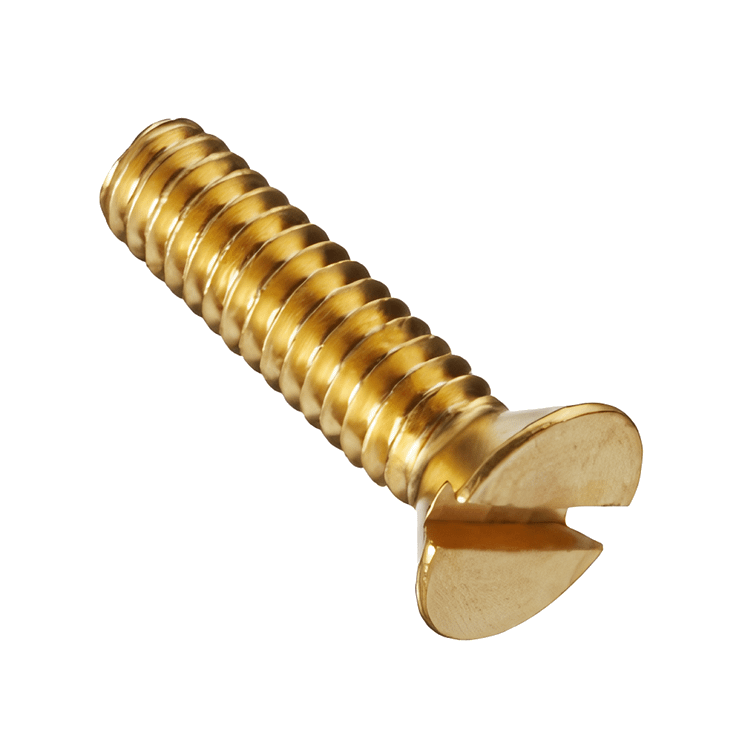

Aesthetic Appeal for Visible Installations

The warm, golden color of brass adds a premium, decorative finish wherever fasteners remain visible. Brass screws and bolts are often specified for:

- High‑end furniture, cabinetry and joinery

- Decorative hardware and architectural details

- Visible fixings on musical instruments, lighting and interior fittings

Their timeless appearance complements both classic and modern designs, enhancing the overall visual quality of finished products.

Versatile Applications Across Sectors

Because brass balances strength, corrosion resistance, conductivity and aesthetics, brass screws and bolts are used across many industries, including:

- Woodworking and furniture: Cabinet screws, trim screws and decorative fixings

- Plumbing and heating: Fastening fittings, flanges and brackets in wet environments

- Marine and offshore: Hardware exposed to salt air and splash zones

- Automotive and machinery: Non‑rusting, conductive fasteners in selected assemblies

This versatility makes brass fasteners a practical standard for manufacturers, installers and repair professionals.

Machinability and Custom Fastener Options

Brass is highly machinable, which supports efficient production of standard and custom fasteners. Brass screws and bolts can be supplied in:

- Multiple thread standards and pitches (metric, UNC/UNF, etc.)

- Various head styles (countersunk, pan, round, hex, socket and more)

- Custom lengths, diameters and special forms based on drawings or samples

This flexibility allows brass fasteners to be tailored to specific applications, ensuring compatibility and optimal performance.

Environmental Sustainability

Brass is fully recyclable and retains its core properties after recycling, which supports more sustainable manufacturing and supply chains. Using brass screws and bolts helps:

- Reduce reliance on virgin raw materials

- Encourage scrap recovery and closed‑loop material use

- Lower waste through long service life and fewer replacements

This makes brass fasteners a responsible choice for projects with environmental and ESG targets.

Conclusion

Brass screws and brass bolts deliver a unique combination of durability, corrosion resistance, electrical conductivity and aesthetic appeal, making them suitable for applications ranging from fine woodworking and decorative fixtures to plumbing, marine and electrical installations. With strong machinability and customization options, brass fasteners provide secure, long‑lasting and visually pleasing connections that support high‑quality construction and manufacturing worldwide.