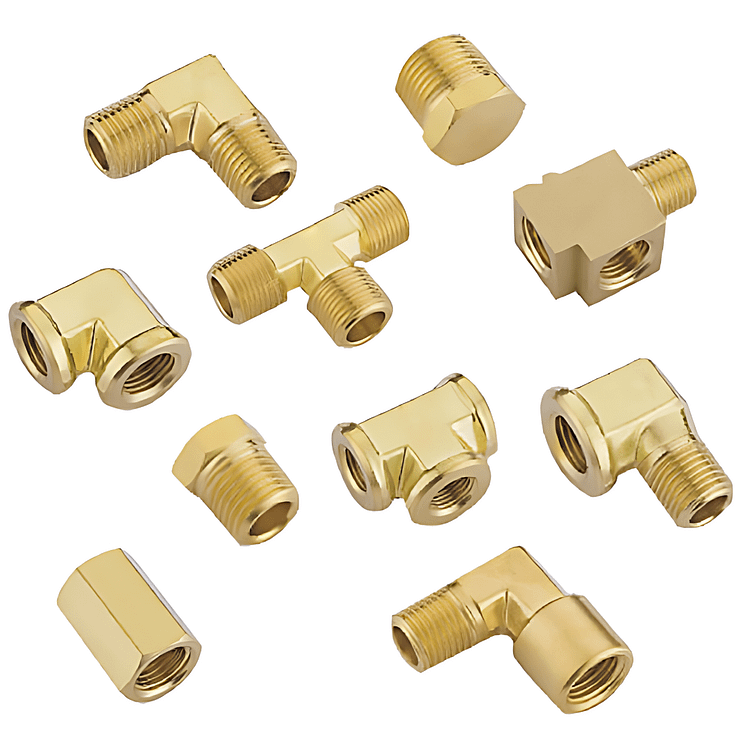

Brass Pipe Fittings for Plumbing, Heating and Gas Systems

Brass pipe fittings are critical components in plumbing, heating and gas distribution systems, used to connect, control and direct the flow of liquids and gases safely. Made from high‑grade copper‑zinc alloys, these fittings offer durability, corrosion resistance and design flexibility, making them a preferred choice for residential, commercial and industrial installations worldwide.

Durability and Mechanical Strength

Brass combines tensile strength with toughness, allowing brass pipe fittings to perform reliably under pressure, temperature changes and mechanical stress. In both domestic and industrial systems, well‑designed brass fittings:

- Withstand high operating pressures without cracking or deforming

- Maintain thread integrity during repeated installation and servicing

- Provide long‑term, leak‑free joints in pipelines and equipment

This robustness supports safer, more reliable water, gas and process‑fluid systems.

Superior Corrosion Resistance

In fluid and gas applications, corrosion can quickly compromise fittings and cause leaks or failures. Brass is naturally resistant to rust and many common chemicals, which makes brass pipe fittings ideal for:

- Potable and non‑potable water supply lines

- Plumbing systems exposed to moisture and varying temperatures

- Many gas and fuel applications where chemical stability is important

This corrosion resistance reduces maintenance requirements and helps extend the service life of complete piping installations.

Versatile Applications Across Liquids and Gases

Brass pipe fittings are used wherever secure, reliable connections are needed in fluid and gas systems. Typical applications include:

- Residential and commercial plumbing: Water supply lines, bathroom and kitchen connections, manifolds and distribution points

- Heating and cooling systems: Boiler connections, radiator circuits, underfloor heating and HVAC piping

- Gas lines and fuel systems: LPG/PNG lines (as permitted by local codes), fuel transfer and low‑pressure industrial gas services

- Industrial processes: Chemical dosing, cooling water, air and inert gas circuits

Their ability to handle both liquids and gases makes brass fittings a practical standard across multiple sectors.

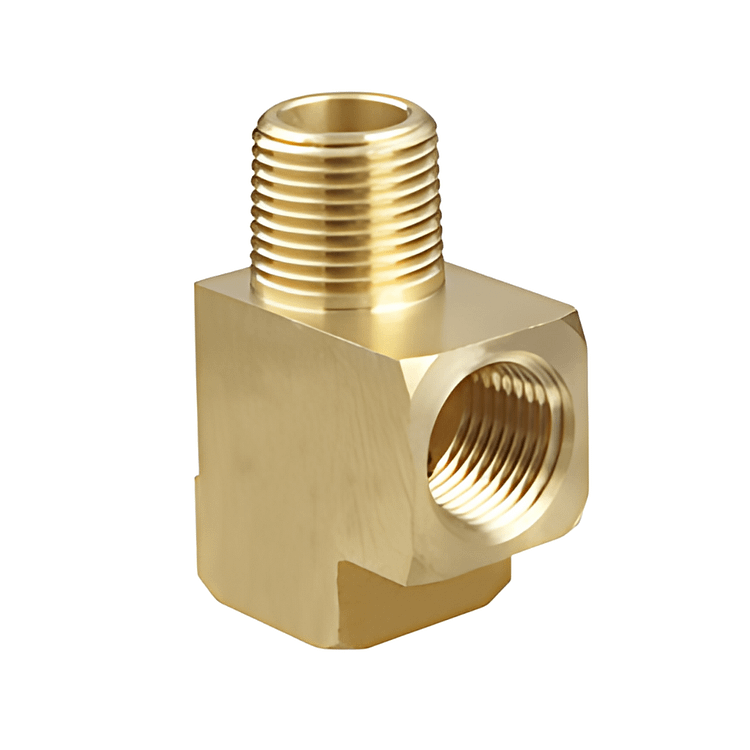

Easy Installation and Multiple Connection Types

Brass pipe fittings are designed for straightforward installation with standard tools, helping installers and maintenance teams work efficiently. They are available in several connection styles, such as:

- Threaded fittings for metal pipes and equipment connections

- Compression fittings for copper and compatible tubing

- Flare and specialized fittings for specific system designs

This range of options allows system designers to choose the most suitable connection method for each application while maintaining reliability and serviceability.

Aesthetic Appeal for Exposed Installations

Where pipework and fittings remain visible—such as in designer bathrooms, open‑plan kitchens or exposed mechanical rooms—the smooth, golden appearance of brass provides a clean, high‑quality look. Brass pipe fittings:

- Complement both traditional and contemporary interior styles

- Offer a premium visual finish for high‑end residential and commercial projects

- Can be polished or left to develop a natural patina, depending on design preferences

This combination of performance and appearance makes brass fittings attractive for both functional and decorative plumbing concepts.

Thermal Conductivity for Heating Applications

Brass’s good thermal conductivity supports efficient heat transfer in heating and cooling circuits. In systems where heat distribution matters, such as:

- Radiator and convector connections

- Underfloor heating manifolds and circuits

- Boiler and heat‑exchanger connections

Brass fittings help maintain stable, even flow and temperature characteristics, contributing to overall system efficiency and comfort.

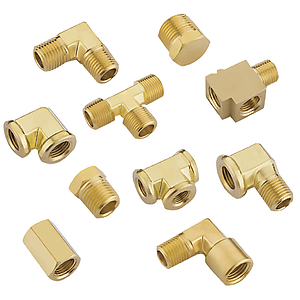

Wide Range and Customization Options

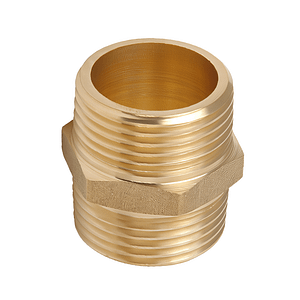

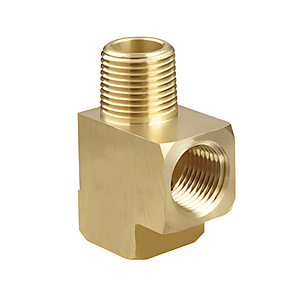

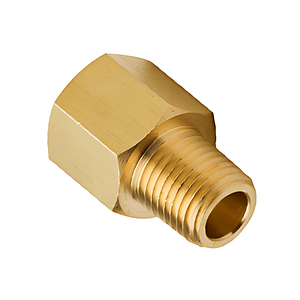

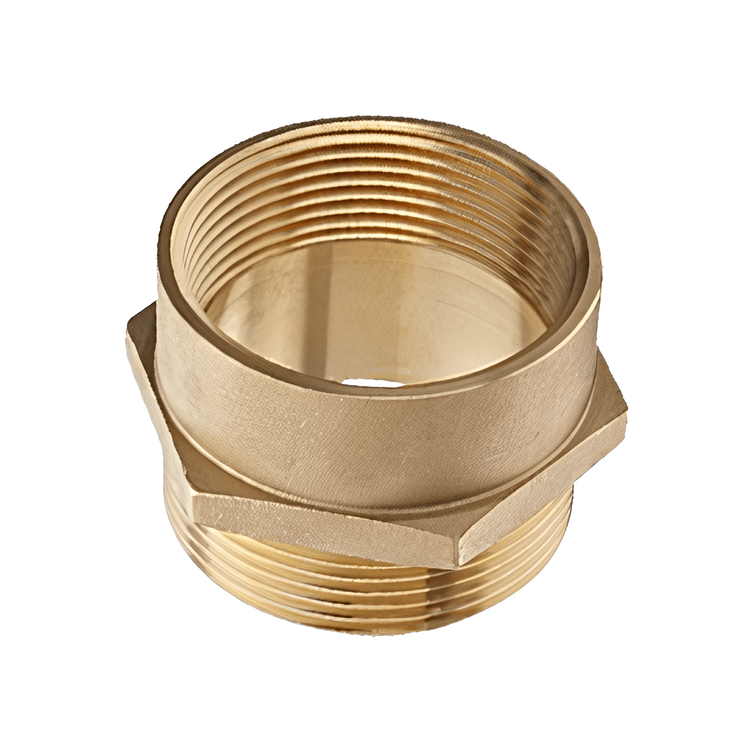

To support different system designs and regional standards, brass pipe fittings are available in a broad range of sizes, shapes and configurations. Common options include:

- Elbows, tees, reducers, unions, nipples, couplings and caps

- Different thread standards (metric, BSP, NPT and others)

- Straight and angled configurations for tight or complex spaces

For specialized projects, fittings can also be manufactured to custom specifications, ensuring compatibility with unique equipment, layouts or performance requirements.

Conclusion

Brass pipe fittings provide a dependable solution for connecting and controlling water, gas and other fluids in plumbing, heating and industrial systems. By combining mechanical strength, corrosion resistance, good thermal properties and visual appeal, they help engineers, installers and building owners achieve long‑lasting, leak‑free and efficient installations. Choosing brass pipe fittings supports reliable system performance, reduced maintenance and a professional finish in applications around the world.