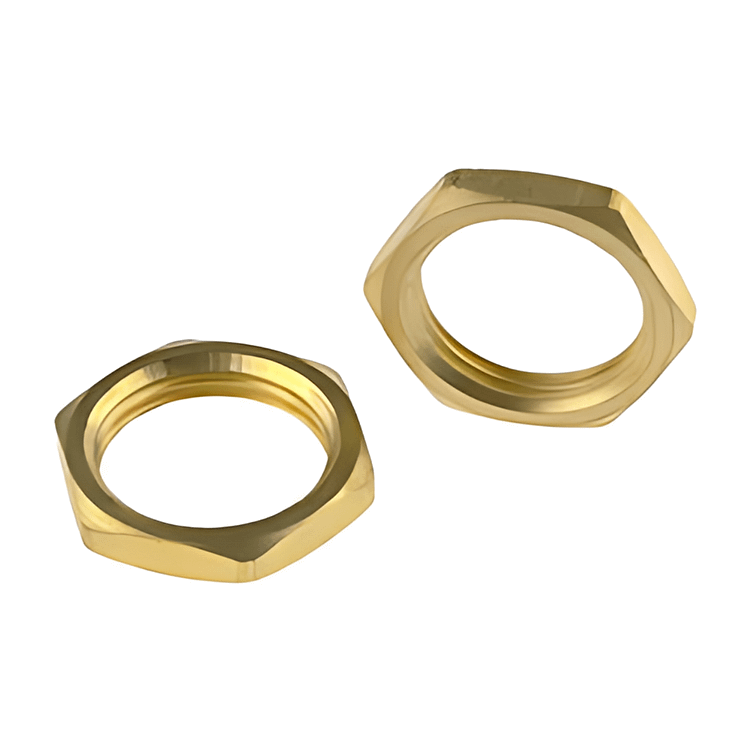

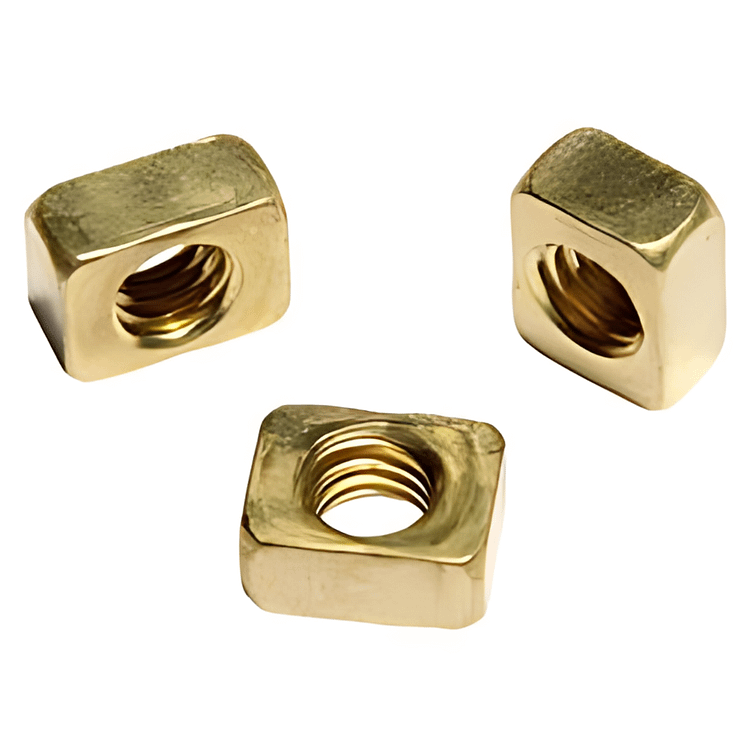

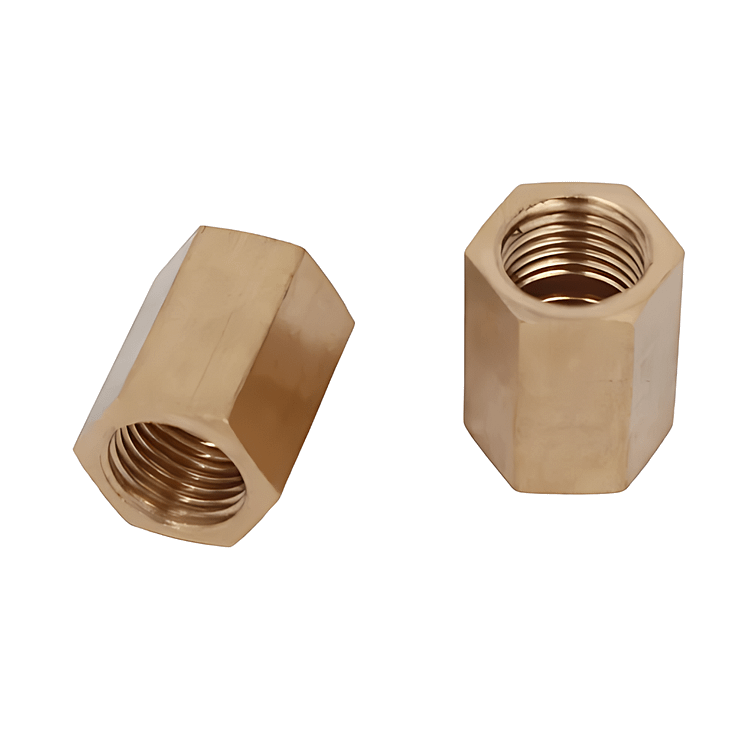

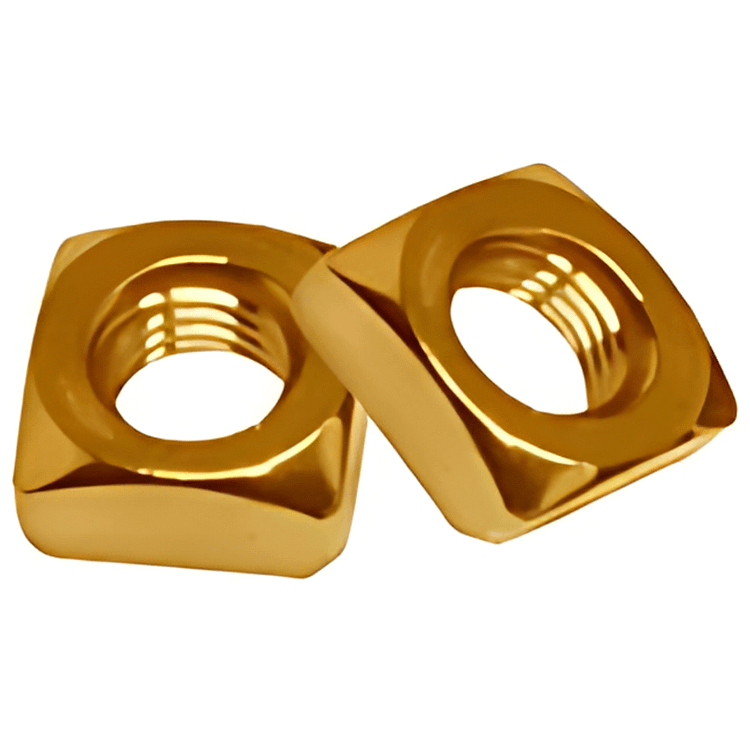

Brass Nuts for Industrial, Electrical and Decorative Applications

Brass nuts are essential threaded fasteners used to secure bolts, screws and studs in applications where strength, corrosion resistance and conductivity are all important. They are widely used in electrical panels, plumbing systems, automotive assemblies, marine hardware, construction fixtures and decorative products across global markets.

Durability and Mechanical Strength

Brass, a copper‑zinc alloy, provides a stable combination of tensile strength and toughness, allowing brass nuts to perform reliably under repeated tightening, vibration and load. Well‑engineered brass nuts:

- Resist deformation and thread damage during assembly and service

- Maintain clamping force over time, supporting joint integrity

- Perform consistently in both light‑duty and heavy‑duty assemblies

This durability helps reduce loosening, failures and unplanned maintenance in equipment and structures.

Corrosion Resistance for Harsh Environments

In many applications, fasteners are exposed to water, humidity, salt spray or mild chemicals. Brass nuts naturally resist rust and many forms of corrosion, making them well suited for:

- Plumbing and sanitary fittings exposed to water and moisture

- Marine and coastal hardware exposed to salt‑laden air

- Outdoor architectural and construction applications

- Industrial equipment that undergoes routine cleaning

By retaining their surface quality and dimensions, brass nuts help maintain secure joints and clean aesthetics over long service periods.

Electrical Conductivity for Panels and Devices

Because brass combines mechanical strength with good electrical conductivity, brass nuts are widely used in electrical and electronic applications where fasteners must also carry or connect current. Typical uses include:

- Electrical panels and switchgear terminals

- Busbar and earthing/grounding connections

- Connectors, clamps and contact assemblies

- Power distribution and control equipment

In these roles, brass nuts support stable, low‑resistance connections, reducing the risk of hot spots and improving overall system reliability.

Versatile Applications Across Industries

Brass nuts can be specified in numerous sectors thanks to their balanced technical and visual properties. Common application areas include:

- Plumbing and HVAC: Securing fittings, valves and brackets in water and gas systems

- Automotive and machinery: Fastening components that need vibration resistance and good appearance

- Electrical and electronics: Terminals, contact assemblies and panel hardware

- Construction and furniture: Visible fixings and hardware elements

- Marine and outdoor products: Fixtures that must resist corrosion while remaining attractive

This versatility makes brass nuts a practical standard choice for OEMs, fabricators and installers.

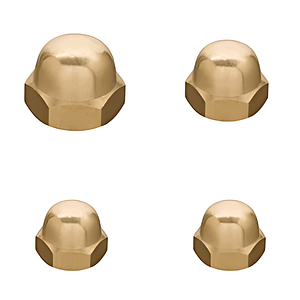

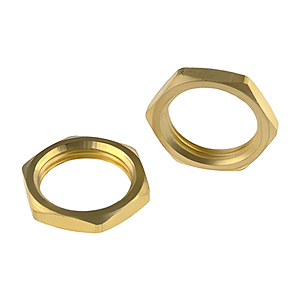

Aesthetic Appeal and Finish Options

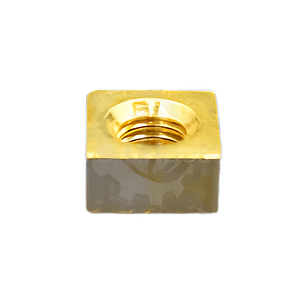

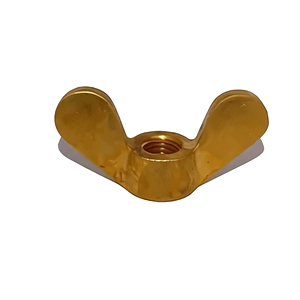

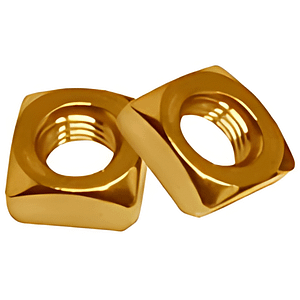

The natural golden color and smooth surface of brass provide a clean, professional look wherever fasteners remain visible. Depending on the design requirement, brass nuts can be:

- Supplied in natural or polished finish for a bright metallic appearance

- Surface‑treated or coated to match specific color and design themes

- Used as a visible design feature in furniture, lighting and architectural hardware

This aesthetic flexibility allows designers to use brass nuts not only for function, but also as part of the overall visual concept.

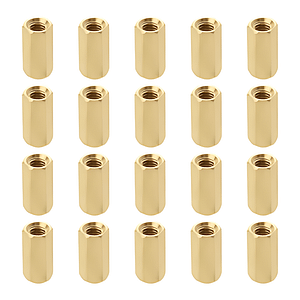

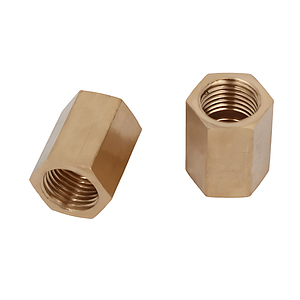

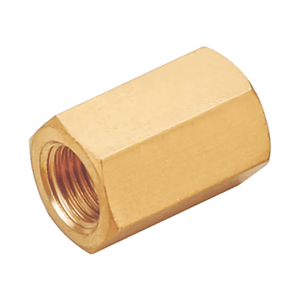

Machinability and Customization

Brass is highly machinable, making it ideal for producing standard and custom nuts with precise threads and complex geometries. Manufacturers can offer brass nuts in:

- Multiple thread standards (metric, UNC/UNF and others)

- Different profiles such as hex, square, coupling and special shapes

- Various heights, widths across flats and bore sizes

- Customized designs based on drawings, samples or CAD data

High machinability supports consistent quality across large production runs while keeping manufacturing efficient and cost‑effective.

Sustainability and Resource Efficiency

Brass is fully recyclable and can be re‑melted without losing its key properties, which supports more sustainable manufacturing and procurement. Using brass nuts helps:

- Reduce dependence on virgin raw materials

- Support scrap recovery and closed‑loop material use

- Align projects with modern environmental and ESG objectives

Long service life further contributes to lower material turnover and reduced waste.

Conclusion

Brass nuts combine mechanical strength, corrosion resistance, electrical conductivity and visual appeal in a single fastener solution. Their wide suitability—from electrical panels and plumbing systems to machinery, marine hardware and decorative fixtures—makes them a preferred choice for manufacturers, engineers, installers and designers worldwide. With excellent machinability and customization options, brass nuts provide reliable, long‑lasting fastening solutions that can be tailored to the technical and aesthetic needs of global applications.