Brass Medical Parts

Precision Brass Medical Parts for Modern Healthcare

Brass medical parts play a critical role in today’s diagnostic, monitoring, and treatment equipment by combining precision machining, reliability, and biocompatibility in a single material. These components are widely used in medical devices, surgical and dental instruments, and life‑supporting systems where accuracy and safety are non‑negotiable. For OEMs, device manufacturers, and medical engineering teams, brass medical components offer an ideal balance of performance, cost, and manufacturability.

Why Brass for Medical Components?

Brass is a copper‑based alloy engineered for applications that demand tight tolerances, repeatable performance, and long service life. In the medical industry, this makes brass an excellent choice for functional parts that must operate reliably under repeated sterilization and continuous use.

Key advantages of brass medical parts include:

- High machinability for complex, tight‑tolerance geometries

- Strength and durability under cyclic loading and handling

- Natural corrosion resistance in harsh clinical environments

- Biocompatibility and antimicrobial properties (in specific alloys)

These properties make brass suitable for both invasive and non‑invasive medical applications, from fluid control and connection to structural and motion components.

Precision and Accuracy in Brass Medical Parts

In medical technology, precision directly influences patient safety, diagnostic accuracy, and device reliability. Brass is renowned for its ability to be CNC machined into highly intricate shapes with stable, repeatable tolerances.

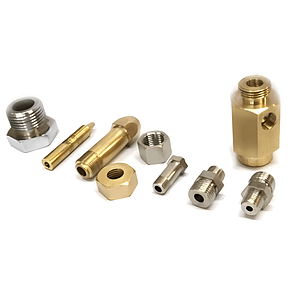

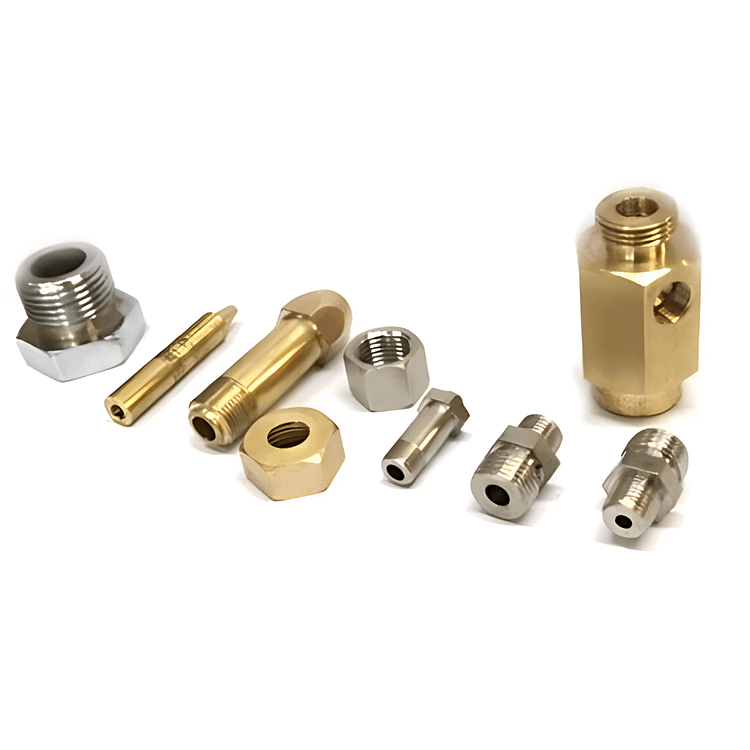

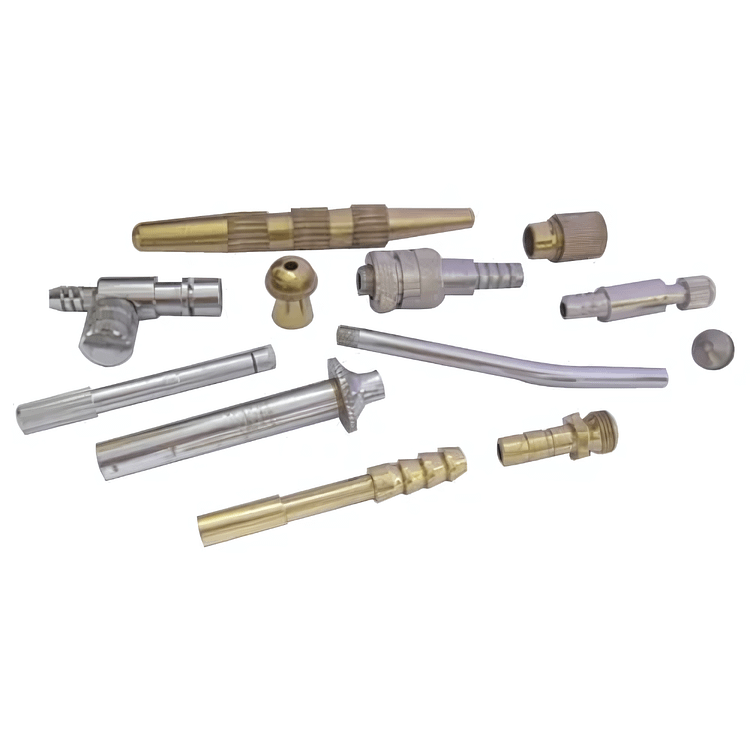

Typical precision‑machined brass medical components include:

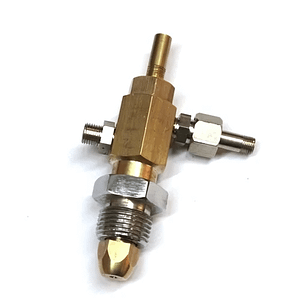

- Micro fittings and connectors for medical tubing and fluid lines

- Housing and internal parts for diagnostic equipment

- Precision elements in blood pressure monitors and imaging devices

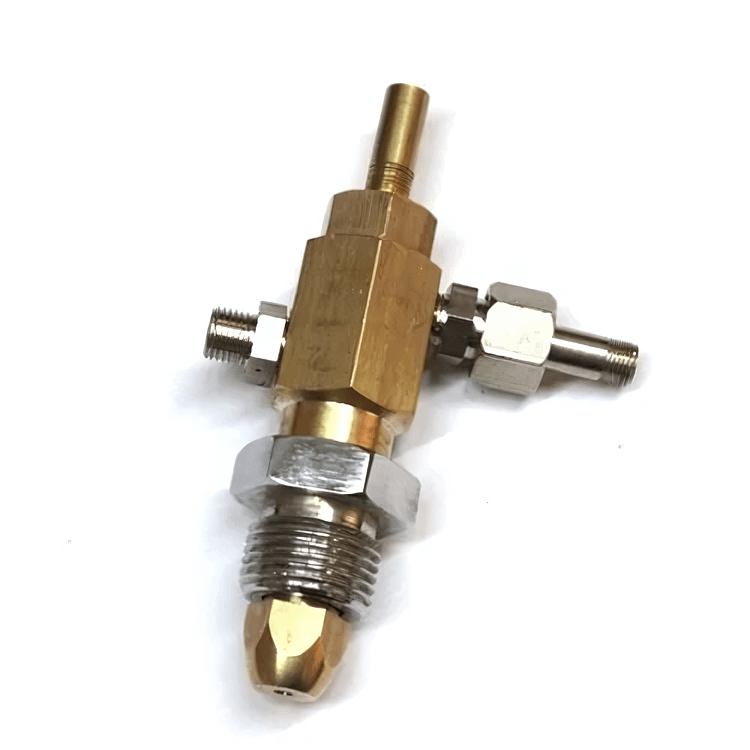

- Valve bodies, stems, and flow‑control components in medical systems

Tight tolerances and stable dimensions help ensure that every connection seals correctly, every reading is accurate, and every mechanical operation is predictable inside critical medical instruments.

Durability and Strength Under Clinical Conditions

Medical devices and instruments are frequently:

- Operated for long hours

- Cleaned and disinfected between uses

- Sterilized using high temperature, pressure, or chemicals

Brass medical parts offer high tensile strength, hardness, and wear resistance, allowing them to withstand repetitive cycles of operation and sterilization without deformation or failure. This durability reduces:

- Component failure rates

- Costly emergency replacements

- Device downtime in clinics and hospitals

Over time, robust brass medical components contribute to a lower total cost of ownership for OEMs, hospitals, and healthcare providers.

Corrosion Resistance and Sterilization Compatibility

In hospitals, labs, and clinics, components must tolerate:

- Autoclaving

- Steam and moist heat

- Chemical disinfectants and cleaning agents

- Exposure to bodily fluids and biological media

Brass is inherently resistant to corrosion and tarnishing when properly selected and finished, making it highly suitable for parts that must maintain surface integrity and functionality after repeated cleaning and sterilization cycles. Correct alloy selection and surface finishing help medical brass components:

- Resist pitting and surface degradation

- Maintain dimensional stability

- Preserve sealing and thread performance over time

Biocompatibility and Antimicrobial Behavior

Biocompatibility is a key requirement for materials used in medical devices, particularly when they come into direct or indirect contact with patients. Certain brass alloys, especially those with higher copper content and controlled composition, can exhibit inherent antimicrobial properties that help limit bacterial growth on component surfaces.

Applications where brass’s biocompatibility and antimicrobial behavior are beneficial include:

- Components in catheters and fluid management systems (non‑implanted)

- Parts of surgical instruments that contact skin or fluids

- Dental tools and accessories

- Contact surfaces in diagnostic and testing equipment

Brass components can be further paired with appropriate coatings and finishes to align with regulatory and clinical requirements for specific device classes.

Versatile Applications of Brass Medical Parts

Brass medical parts are found across a wide range of healthcare applications, supporting everything from routine examinations to critical care and advanced therapies.

Common use cases include:

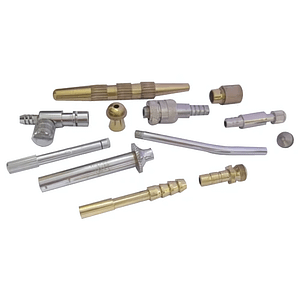

- Connectors, couplings, and fittings for medical tubing and gas lines

- Components in diagnostic and monitoring devices (ECG, blood pressure, imaging, and lab analyzers)

- Parts for surgical instruments, dental tools, and endoscopy equipment

- Structural and functional elements in prosthetic devices and orthopedic systems

- Precision fittings and interfaces in rehabilitation and physiotherapy equipment

This versatility makes brass an excellent platform material for medical OEMs seeking a balance of manufacturability, performance, and flexibility.

Customization, CNC Machining, and Design Flexibility

For modern medical devices, off‑the‑shelf components rarely meet every design requirement. Brass’s outstanding machinability makes it ideal for custom CNC machining, turning, and milling of complex medical geometries.

With advanced CNC machining capabilities, brass medical parts can be customized to:

- Match unique device designs and interface requirements

- Integrate multiple functions into single, compact components

- Achieve specific flow characteristics, mechanical performance, or assembly constraints

- Support fast prototyping and smooth transition to high‑volume production

This adaptability enables faster innovation cycles and more robust designs for medical OEMs and engineering teams.

Functional and Aesthetic Benefits in Medical Devices

Beyond mechanical performance, brass offers several functional and visual advantages that support both engineering and user experience:

- Smooth, polished surfaces that are easy to clean and visually professional

- Non‑magnetic behavior in many brass alloys, beneficial near sensitive imaging systems and electronics

- A high‑quality appearance that supports perception of reliability and hygiene in clinical environments

These traits matter in medical and dental settings, where the look and feel of instruments can influence user trust and confidence.

Why Choose Boltorq BrassMet for Brass Medical Parts?

Working with a dedicated brass component specialist brings better control over quality, material selection, and delivery reliability. Boltorq BrassMet offers:

- Precision CNC machining for complex brass medical geometries

- Support for tight tolerances and demanding surface finish requirements

- Material guidance for alloy selection based on application, sterilization method, and regulatory needs

- Scalable production capacity for prototypes, pilot batches, and full‑scale manufacturing

Our team collaborates closely with design, sourcing, and quality teams to ensure that each brass medical component meets your technical, functional, and compliance expectations.