Brass Meter Parts for Accurate Measurement

Brass meter parts are critical components in water meters, gas meters, energy meters, heat meters and flow meters where accurate measurement and long‑term reliability are essential for billing and resource management. Manufactured from high‑grade brass alloys, these components combine durability, corrosion resistance and precision engineering, making them a preferred choice for meter manufacturers and utilities in residential, commercial and industrial sectors.

Why Brass is Preferred for Meter Components

Brass, a copper‑zinc alloy, offers an excellent balance of mechanical strength, machinability, and corrosion resistance, which is why it is widely used in metering applications worldwide. For OEMs and meter assemblers, brass meter parts deliver stable performance under continuous operation and variable field conditions.

Key properties that make brass ideal for meter parts:

Exceptional Durability for Long‑Life Metering Systems

Metering devices are designed for years of service in the field, often with minimal maintenance access. Brass meter parts offer the durability needed to support such long life cycles.

- Withstand continuous flow, pressure fluctuations, and vibration in pipelines

- Resist wear and deformation in moving or load‑bearing assemblies

- Reduce replacement frequency and lifecycle cost of complete meters

This durability is especially valuable for utilities and OEMs targeting reliable, low‑maintenance metering solutions across large networks.

Corrosion Resistance in Water, Gas and Outdoor Environments

Water and gas meters are commonly installed outdoors, in chambers, basements or industrial areas where they face moisture, temperature variations and contaminants. Brass’s inherent corrosion resistance helps meter components keep their structural integrity and sealing performance over time.

Typical exposure conditions where brass meter parts perform reliably:

- Municipal and industrial water distribution lines

- LPG, PNG, CNG and other gas distribution systems

- Outdoor installations exposed to humidity and weather

- Industrial plants with process vapours and chemical splash

Corrosion‑resistant brass meter components help maintain accurate readings, minimize leakage, and extend service intervals.

Precision and Accuracy: Tight‑Tolerance Brass Meter Parts

Accurate metering is fundamental for fair billing and efficient resource management. Brass’s machinability enables the production of precision components with tight tolerances, smooth threads, and consistent sealing surfaces.

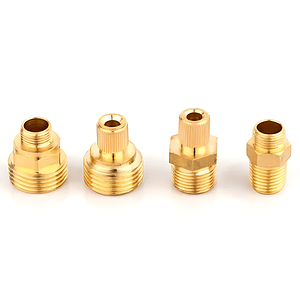

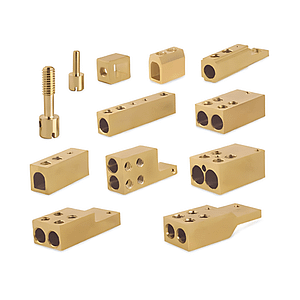

Common precision‑engineered brass meter parts include:

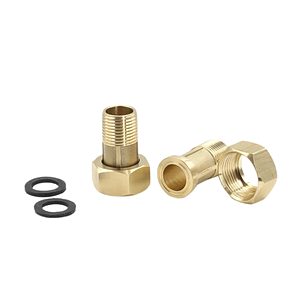

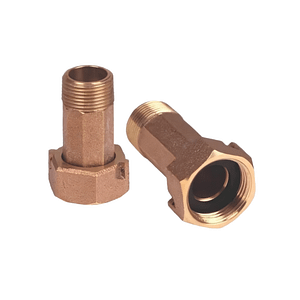

- Couplings, nuts, and bodies for water meter connections

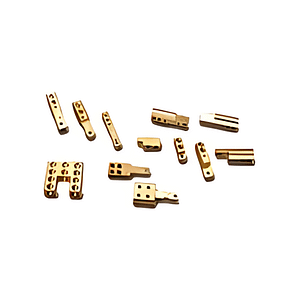

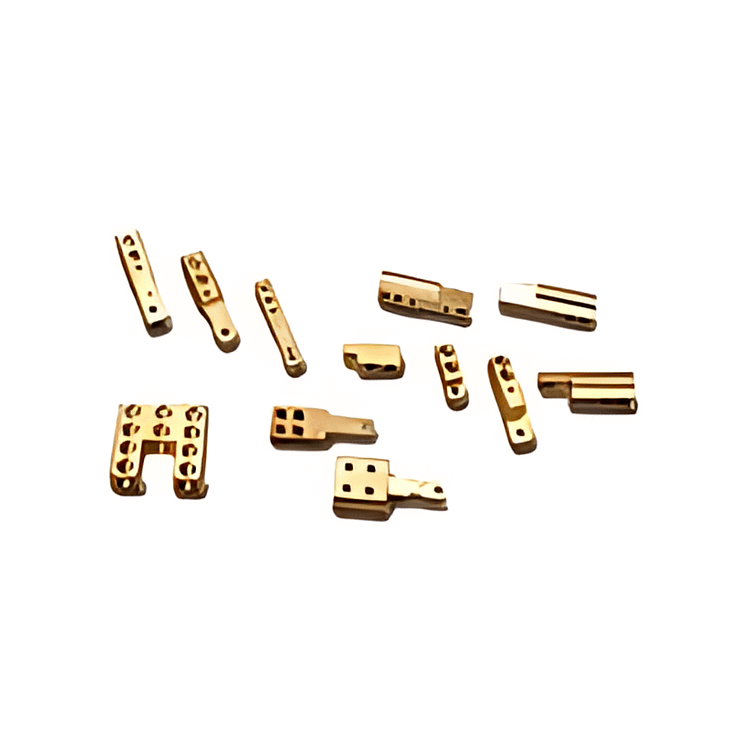

- Terminals, links, and screws for energy/electricity meters

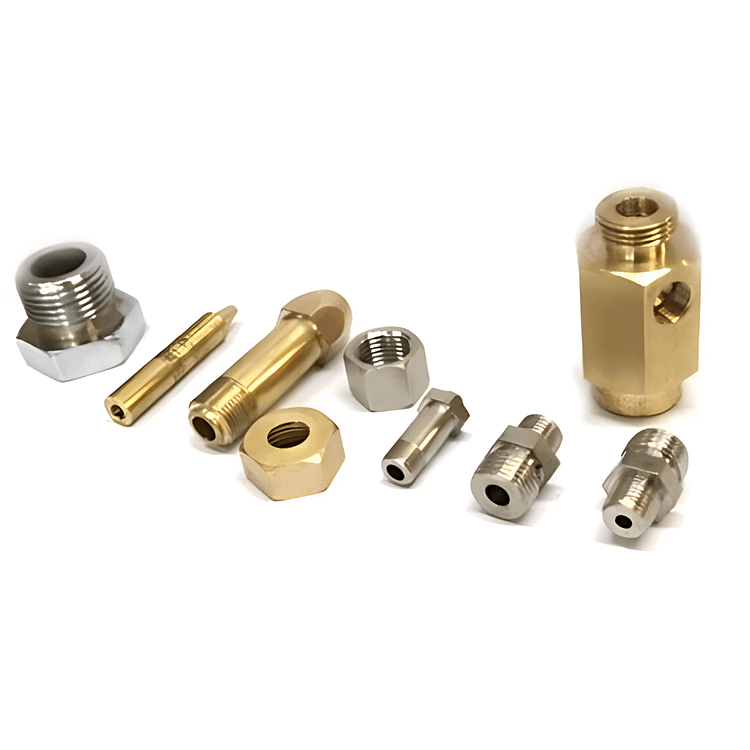

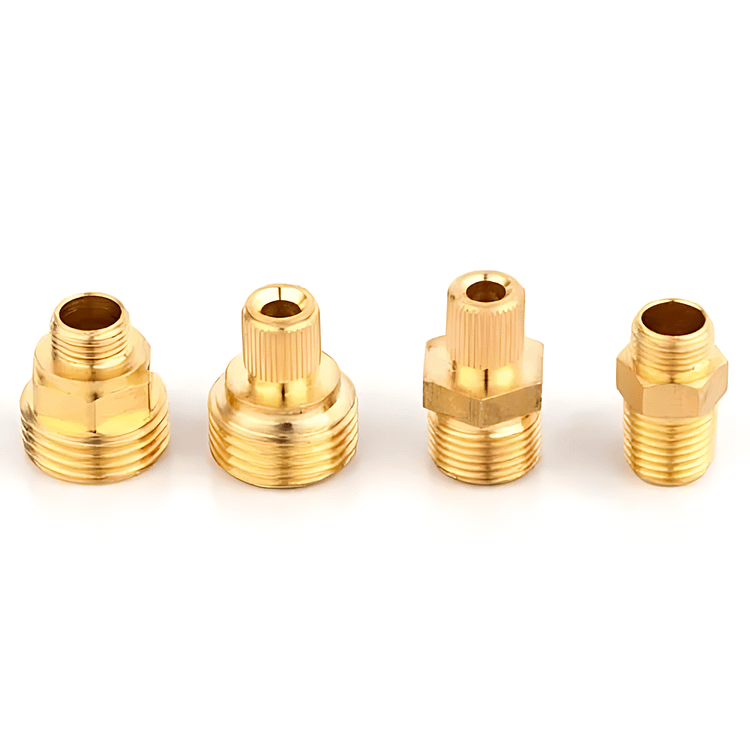

- Fittings and valve components for gas meters and fuel meters

- Inserts, gears, and internal elements for heat and flow meters

Consistent dimensions and surface finishes help ensure accurate flow measurement, stable electrical contact, and reliable mechanical operation through the life of the meter.

Wide Application Range Across Meter Types

Brass meter parts are used across multiple metering technologies and industries, making them a versatile choice for manufacturers and integrators.

Typical applications:

- Water meters: Bodies, couplings, connectors, and fittings for residential, commercial and industrial water metering.

- Gas meters: Brass meter parts for LPG, PNG, CNG and industrial gas metering, including precision fittings and internal components.

- Energy/electricity meters: Terminals, links, screws and other brass energy meter components for single‑phase and three‑phase meters.

- Heat meters: Brass parts in heat and BTU meters for thermal energy measurement in heating and cooling systems.

- Flow and pressure meters: Brass fittings, housings and couplings in flow meters and pressure gauges used in pipelines and process systems.

- Fuel meters: Brass components in fuel dispensing, vehicle fuel meters and machinery fuel measurement systems.

Custom Brass Meter Parts and CNC Machining Capability

Standard off‑the‑shelf parts cannot cover every OEM requirement, so customization is key in modern metering projects. With CNC machining and precision turning, brass meter parts can be tailored to unique product designs.

Customization options include:

- Sizes and dimensions as per drawing, sample, or specification

- Different thread types and forms for global standards

- Custom shapes: round, hex, long, stepped and special profiles

- Material grades and alloy compositions per application needs

CNC‑machined brass meter components ensure repeatability across large production runs, supporting both domestic and export‑grade metering products.

Surface Finishes, Testing and Quality Standards

For meter manufacturers, consistent quality is as important as design. Brass meter parts can be supplied with various finishes and are tested to meet relevant industry and customer standards.

Typical surface finishes:

- Natural brass or nitric‑washed clean finish

- Nickel plating, chrome plating or electro‑tinning

- Special coatings or treatments for enhanced corrosion resistance

Quality and testing practices:

Key Benefits of Brass Meter Parts

Using brass for meter components provides a balanced combination of performance, cost, and sustainability.

Main benefits:

- Durability: Long service life under mechanical stress and environmental exposure.

- Corrosion resistance: Reliable operation in water, gas, and outdoor conditions.

- Precision: Tight‑tolerance machining for accurate measurement and stable connections.

- Versatility: Suitable for water, gas, energy, heat, flow, and fuel metering systems.

- Low maintenance: Minimal upkeep required; periodic inspection and cleaning are often sufficient.

- Conductivity: Good electrical and thermal conductivity for energy and heat meter applications.

- Recyclability: Brass is recyclable, supporting sustainability and circular‑economy initiatives.

- Cost‑effectiveness: Competitive total cost of ownership due to long life and stable performance.