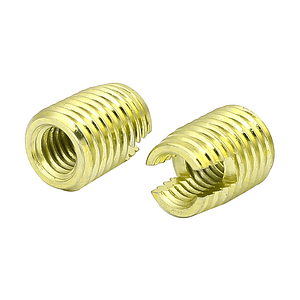

Brass Inserts

Brass inserts are essential components used to reinforce and provide reliable threaded connections in various materials, including plastics, wood, and metal. These inserts feature internal threads and are designed to be embedded or pressed into pre-drilled holes or molded recesses, creating durable and secure fastening points. Crafted from high-quality brass alloys, these inserts offer exceptional strength, corrosion resistance, and versatility, making them a preferred choice for a wide range of applications across industries.

Reinforcing Threaded Connections

One of the primary functions of brass inserts is to reinforce threaded connections in materials that may not offer sufficient strength or durability on their own. By embedding brass inserts into plastic, wood, or composite materials, manufacturers can create reliable and long-lasting threaded fastening points. This reinforcement prevents thread stripping, pull-out, or loosening over time, ensuring the integrity and reliability of assemblies in various applications, including furniture, electronics, automotive, and consumer products.

Versatility in Material Compatibility

Brass inserts are compatible with a wide range of materials, making them suitable for diverse applications and industries. Whether used in thermoplastics, thermosets, wood, or metal, brass inserts provide secure and stable threaded connections that withstand various environmental conditions and loads. The versatility of brass inserts allows for seamless integration into different materials and manufacturing processes, offering flexibility in design and assembly.

Superior Strength and Durability

Brass inserts offer superior mechanical properties, including high tensile strength, hardness, and toughness, ensuring reliable performance in demanding applications. Unlike plastic or aluminum inserts, brass inserts provide robust threaded connections that can withstand high loads, vibrations, and temperature fluctuations. This strength and durability make brass inserts suitable for critical applications where safety, reliability, and longevity are paramount.

Corrosion Resistance

Brass inserts are inherently resistant to corrosion, making them suitable for use in indoor and outdoor environments. Brass, an alloy of copper and zinc, offers excellent resistance to rust, oxidation, and chemical corrosion, ensuring long-lasting performance even in harsh conditions. This corrosion resistance protects brass inserts from degradation over time, maintaining their integrity and reliability in various applications, including marine, automotive, and industrial settings.

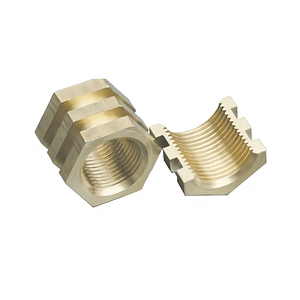

Easy Installation and Assembly

Installing brass inserts is a straightforward process that requires minimal tools and expertise. Inserts can be pressed, molded, or heat-inserted into pre-drilled holes or molded recesses, depending on the application and material. Once installed, brass inserts provide immediate threaded connections that are ready for fastening with screws, bolts, or studs. This ease of installation streamlines assembly processes, reducing production time and costs while ensuring consistent and reliable results.

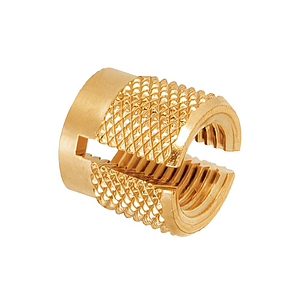

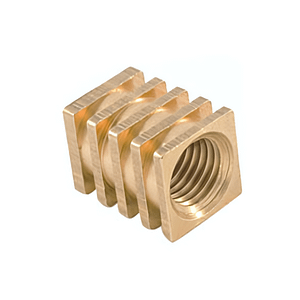

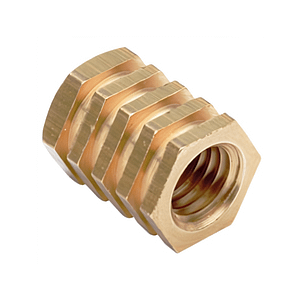

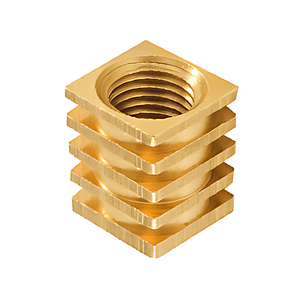

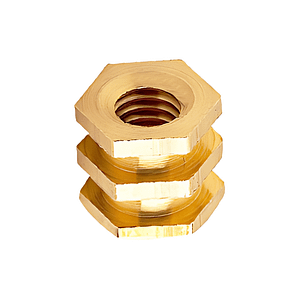

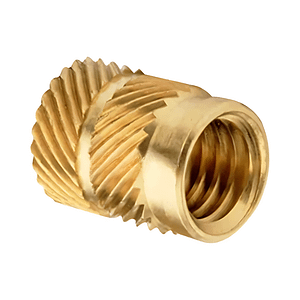

Customization Options

Brass inserts are available in a variety of sizes, thread types, and configurations to suit different applications and design requirements. Whether for metric or imperial threads, coarse or fine pitches, standard or custom lengths, brass inserts can be tailored to meet specific project needs. Additionally, inserts may feature knurled or flanged exteriors for enhanced retention and stability in the host material, providing added security in critical applications.

Conclusion

Brass inserts are indispensable components that provide strength, reliability, and versatility in threaded connections across industries. Whether used in plastics, wood, or metal, brass inserts offer superior mechanical properties, corrosion resistance, and ease of installation, making them an ideal choice for a wide range of applications. With their ability to reinforce threaded connections, brass inserts enhance the integrity and durability of assemblies, ensuring long-lasting performance and reliability in diverse environments.